- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- waste drying

Results for

Waste drying - Import export

FLOTTWEG SE

Germany

Transport and disposal costs, at over 70 percent, represent by far the largest cost item in sludge dewatering. A powerful dewatering assembly is thus an important criterion. With a Flottweg HTS Decanter in the C series, you can achieve the highest possible total dry solids in the dewatered sludge, thereby continuously saving on transport and disposal. More than 50 years of experience in the dewatering of sewage sludge and continuous further development have gone into the design of the Flottweg HTS Decanter. This experience, combined with references from the entire world, makes Flottweg one of the leading providers of mechanical separation technology. The HTS Decanter is attractive for its performance, its efficiency, and its high cost-effectiveness. The decanters in the Flottweg C series cover a throughput range from about 5 to over 150 cubic meters per hour. We can offer you comprehensive know-how and customized systems.

Request for a quote

MACFAB SYSTEMS LTD

Ireland

The MACFAB Bag Press Compacts waste into a chamber lined with a black refuse bag. Once completed the full refuse bag of compacted waste takes up less space.

Request for a quote

TEKNOVA PRINTING AND CHEMICAL INDUSTRY TRADE

Turkey

Turquoise SF is designed for today’s generatİon of high speedsheet-fed presses which is a high- tech, high performance fountain solution and FOGRA approved one it gives clean and quick start up with reduced ink consumption.This allows to printers to work with less water,less ink consumption, quick dry and less waste. Becauseof Teknova has sophisticated technoolgy we also offer to printers more healthy and safe products with a very effective preservative ingridents which prevents bacteria growth.In pipe sand dampening system. TurquoiseSF has alcohol reduction system, anti foaming agent and fully biodegradable system in its formulation. PROPERTIES Easyand quick start up.Noneedto change the press adjustme nt s Minimumink emulsifıcations,oink can stayconsistentduring pres run. Veryquİck adoptatİon wİth dİfferent ink andpaper qualİty Enables IPA usage quickly reduced down to %50 with no noticeable loss of performance, so enjoy the benefits of reduced cost.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

If no procedures for biological or chemical exhaiust air cleaning are to be used efficiently, the thermal treatment is regarded as method of choice. The basic thermal processes are Recuperative thermal oxidation Regenerative thermal oxidation Catalytic oxidation. The focus of our products lies particularly in the periphery of especially challenging special solutions Waste treatment Sewage sludge drying Waste water treatment Landfill aftercare Specialpurpose solutions for the chemical industry Food industry In general at corrosive media, at risk of condensation, and especially high specifications for the pure gas Since 2018 we are working close with our sister company Airprotech Srl. from Magenta/Italy in the field of thermal exhaust air cleaning. Beside our core products our range of products in the field thermal exhaust air cleaning is broadened Airprotech is specialised in the development, the manufacture and the supply of turnkey plants for thermal cleaning

Request for a quote

RAYPA

Spain

The AE-DRY floor standing automatic vertical autoclaves with top loading access deliver great performance for general labware sterilization in many industries, educational and medical facilities and research institutes with the aim of increasing the productivity of the laboratory The AE-DRY autoclaves are intended for the sterilization of a wide range of solid materials such as unwrapped and wrapped items, small porous objects and hollow ware type B (slightly deep and broad cavities), glass, plastic, metallic objects and waste bags. The drying feature and the automatic water control level reduce operator time dedicated to the autoclave leading to facilitate the sterilization procedures in the general laboratory. Contact us now or visit our website for more information.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

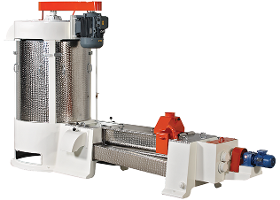

PARSMEGA MAKINA

Turkey

It cleans the stone, soil, all dust particles and bacteria of the wheat with water. It has a double seal device that prevents oil and water from mixing. The entry point of the wheat into the washing tub is moved back and forth to adjust the time the wheat stays in the water. The upper screw rotates rapidly and agitates the water, performing the washing process. Foreign materials (stones, etc.) heavier than wheat sink to the bottom and are thrown out by the gizzard screw rotating in the opposite direction. Light substances such as dust, straw and garbage in the wheat are collected on the surface of the water and thrown out with water through the husk hole. The wheat dragged by the upper screw goes to the vertical drying section working with the centrifugal system. Rapidly rotating pallets in vertical drying throw the product towards

Request for a quoteResults for

Waste drying - Import exportNumber of results

7 ProductsCountries

Company type