- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- used milling machine

Results for

Used milling machine - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories of printer, which function is for support stand.They were made by aluminum, then use CNC Milling machine to process, then doing black anodize.

Request for a quote

SIKO GMBH

Germany

Profile DA10R/1: Version with two counters (4 or 5 decades) and fine reading Predestined for use with wood milling machines Hollow shaft, max. Ø 35 mm Display can be designed for “mm” or “inch”

Request for a quote

SIKO GMBH

Germany

Version with two counters (4 or 5 decades) and fine reading. Predestined for use with wood milling machines. Hollow shaft, max. Ø 30 mm. Display can be designed for “mm” or “inch”.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

The question of the ideal milling cutter is dependent upon the material to be machined. A single-tooth cutter is often an advantage for ""soft"" materials (PVC, Perspex, Kömacel, etc), wooden materials (chip- or flakeboard) and non-ferrous metals (soft aluminium, Alcubond, etc.), as the problem of cutting erosion in comparison to clogging recedes. A double flute is better suited to very hard plastics and harder types of aluminium (short chipping). Milling cutters with 4 or more flutes are predominantly used to mill metals. SINGLE-TOOTH MILLING CUTTERS Single-tooth milling cutters are mainly used for machining ""soft"" materials. Their extra large chipping space guarantees an ideal chipping removal and high stock removal rate. MULTI-TOOTH MILLING CUTTERS Multi-tooth milling cutters are used for machining ""harder"" materials. Smoother running is achieved, as several cutting edges are always in contact. The more flutes the tool has, the smaller the individual chippings will be.

Request for a quote

MVA D.O.O.

Slovenia

Using modern CNC turning and milling machines we achieve fast and precise machining of casted parts.

Request for a quote

MVA D.O.O.

Slovenia

Using different CNC turning and milling machines we can manufacture metal parts made from various materials and provide galvanic or other types of coatings.

Request for a quote

INOTECH MACHINING SRL

Romania

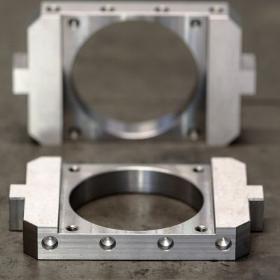

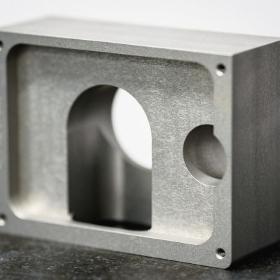

We manufacture milled parts in all dimensions and shapes: from large milled workpieces to small parts that require increased precision. We have extensive experience in manufacturing custom milled parts for various industries and uses: the heavy industry, the automotive and aeronautics industry, the food and agriculture sector, the medical, research, and pharma sectors. Our modern park of CNC milling machines allow us to deliver flawless milled parts in the shortest time. - 3axis, 4 axis, and 5 axis machines. - From 10 x 10 x 10mm to 2000 x 10000 x 1500mm. The materials we usually use are steel, stainless steel, and aluminum but we can also use brass, cast iron, plastic.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconium oxide jars 60 times the hardness of regular steel, highly wear-resistant and resistant to acid and solvents. The grinding jars are extensively applied to in the fields of Paint, Ink, Geology, Metallurgy, Electronics, Construction Material, Ceramics, Chemical Engineering, Light Industry, Medicine, Environmental Protection and so on. Each jar set includes grinding jar, jar lid, rubber sealing gasket and different sizes of mixed zirconium oxide grinding balls. Specification: .High cost-effective, low wear and long lifetime. .High specific gravity, high efficiency. .Highly wear resistant to acid and solvents. .Highly polished, smooth, easy to clean, low abrasion to the equipment. .High mechanical strength, good toughness, impact resistance, no broken beads. .Mainly used for lab planetary ball mill machines.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture milled parts in all dimensions and shapes: from large milled workpieces to small parts that require increased precision. We have extensive experience in manufacturing custom milled parts for various industries and uses: the heavy industry, the automotive and aeronautics industry, the food and agriculture sector, the medical, research, and pharma sectors. Our modern park of CNC milling machines allow us to deliver flawless milled parts in the shortest time. - 3axis, 4 axis, and 5 axis machines. - From 10 x 10 x 10mm to 2000 x 10000 x 1500mm. The materials we usually use are steel, stainless steel, and aluminum but we can also use brass, cast iron, plastic.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture milled parts in all dimensions and shapes: from large milled workpieces to small parts that require increased precision. We have extensive experience in manufacturing custom milled parts for various industries and uses: the heavy industry, the automotive and aeronautics industry, the food and agriculture sector, the medical, research, and pharma sectors. Our modern park of CNC milling machines allow us to deliver flawless milled parts in the shortest time. - 3axis, 4 axis, and 5 axis machines. - From 10 x 10 x 10mm to 2000 x 10000 x 1500mm. The materials we usually use are steel, stainless steel, and aluminum but we can also use brass, cast iron, plastic.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture milled parts in all dimensions and shapes: from large milled workpieces to small parts that require increased precision. We have extensive experience in manufacturing custom milled parts for various industries and uses: the heavy industry, the automotive and aeronautics industry, the food and agriculture sector, the medical, research, and pharma sectors. Our modern park of CNC milling machines allow us to deliver flawless milled parts in the shortest time. - 3axis, 4 axis, and 5 axis machines. - From 10 x 10 x 10mm to 2000 x 10000 x 1500mm. The materials we usually use are steel, stainless steel, and aluminum but we can also use brass, cast iron, plastic.

Request for a quote

INOTECH MACHINING SRL

Romania

We manufacture milled parts in all dimensions and shapes: from large milled workpieces to small parts that require increased precision. We have extensive experience in manufacturing custom milled parts for various industries and uses: the heavy industry, the automotive and aeronautics industry, the food and agriculture sector, the medical, research, and pharma sectors. Our modern park of CNC milling machines allow us to deliver flawless milled parts in the shortest time. - 3axis, 4 axis, and 5 axis machines. - From 10 x 10 x 10mm to 2000 x 10000 x 1500mm. The materials we usually use are steel, stainless steel, and aluminum but we can also use brass, cast iron, plastic.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg offers the highest-quality precision machined mill-turned parts that are engineered to fit your specific application needs. Our CNC mill-turn machining utilizes the latest technology and the highest level of craftsmanship to create parts with the perfect fit and accuracy for any project. What is Mill-Turn Machining? Mill-turn machining is a type of precision CNC machining that uses advanced machines to create a variety of complex parts. The machines used for mill-turn machining combine both milling and turning operations into one setup. Capable of performing multiple simultaneous operations such as drilling, milling, and tapping, mill-turn machining is ideal for parts that require complicated geometries. We Specialize In: Multi-Axis Machining Milling Turning Thread Milling Drilling Tapping Slotting Chamfering Common Applications for Mill-Turned Parts is automotive, medical, aerospace, and food & beverage, etc. Contact us: sales@mxmparts.com

Request for a quote

TECHNOGROUP

Bulgaria

We are using CNC-Lathe and CNC-Milling machines in the detail manufacture. Thanks to our partners, we have succeeded to launch serial production and within the frames of low tolerance of materials of all kinds and quantities.

Request for a quote

MECANUMERIC

France

Designed for fine, precise, intensive works in small formats, the CharlyDMCII milling machines are used for many applications: metal engraving, fine machining, plasturgy, design, rapid prototyping, electronics… STRENGTHS • Rigid steel/cast aluminium structure. • Double guide grinded steel prismatic rails and preloaded ball beatings. • Transmission by ball screws. • Fixed table / mobile gantry kinematics • Available in servo-brushless motorization. • Economical version with step by step motorization. • Design and ergonomy. • Small footprint. • Available with automatic tool change. • Very high frequency spindle for machining and fine works. • Parts held by vacuum table (option). • ISO programming, industry standard. • Machining of soft materials and metals. • Quality and industrial performances of Charlyrobot machines. • Compliant with European safety directive Machine 2006/42/CE. Models DMCII 301/303 DMCII 601/603 DMCII 6121/6123 X stroke 310 mm 610 mm 610 mm Y stroke (without...

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling and boring machines, as well as machining centers. While the controls have undergone continuous development during this period, the basic operational technique has remained the same. You will find also these principles implemented in the TNC 640, the HEIDENHAIN contouring control for milling and milling/turning operations: shop-oriented programmability with graphic support, many field-proven cycles and an operational design you'll recognize from other HEIDENHAIN controls. Shop-oriented programming You program conventional milling and drilling operations, and with the TNC 640 also turning operations, yourself at the machine, in plain language dialog—the workshop-oriented programming language from HEIDENHAIN. The TNC 640 provides you with optimum support with practical prompts, questions and expressive graphical aids—for turning operations, too.

Request for a quote

MANTIS CHEMIE GMBH

Germany

The PMMA BLANK is developed to be used in milling machines for making temporary restorations, for gingiva formation after placing dental implants and for accurate determination of the occlusal contacts before placing zirconium prosthetic structures. The WAX BLANK are used in the fabrication of wax modeling, in the lost wax process for casting, making denture restorations and for frameworks for crown and bridge models . It was developed for cast and pressing techniques.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

AHP PLASTIK MAKINA

Turkey

Different forms of radius notches can be machined according to various Standards.The notches are at different radius and angles. Micrometer notches at 0.01 sensitivity. Continuous machining is possible with electric motors. 1 TS EN ISO 179-1 A type notch knife is given together with the machine. Notch knives for various Standards(optional); ISO 180 Type A, Type B ISO 179 Type A, Type B, Type C

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

F. ZIMMERMANN GMBH

Germany

With the FZ100 Portal Milling Machine Zimmermann has managed to achieve 6-axis machining using the patented in-house developed M3ABC 3-axis Milling Head. This concept sets new standards in the volume machining of aluminium, composite and model making materials as well as in the High Speed Cutting of steel and cast iron, where conventional 2-axis fork heads with A- and C-axis have long reached their limits in the 5-axis simultaneous machining. Advantages: - Machining four times faster is possible - Perfect quality thanks to the six axes - Highest accuracy possible

Request for a quote

F. ZIMMERMANN GMBH

Germany

The 5-axis portal milling machine FZ 25 is a universal solution for the machining of highly complex and at the same time voluminous components. Model materials as well as composites through to light alloys can all be machined with this HSC gantry machine. This machine range fulfils the specific requirements of many sectors: - In the automobile design where large models need to be produced (e. g. cars on a scale of 1:1). - In pattern and tool making, especially in connection with very large workpieces with deep contours need to be machined (e. g. large rotation-symmetric moulds such as tanks and pools, etc.). - In the boatbuilding and shipbuilding industries, where huge work areas are required in all three axes, since the components are often elongated in shape. - In the aircraft industry, e. g. for milling panels, other large parts and components with extreme contours. In the wind energy industry with its long thin blades and bulbous hubs.

Request for a quoteResults for

Used milling machine - Import exportNumber of results

36 ProductsCompany type

Category

- Milling - machine tools (12)

- Milling - steels and metals (7)

- Machine tools - metal machining (5)

- Ceramics, industrial (1)

- Dentistry - products (1)

- Labelling machines (1)

- Mechanical transmission - components (1)

- Milling - woodworking machinery (1)

- Numerical control systems - minicomputers and mainframes (1)

- Perforation of steels and metals (1)

- Precision engineering - portable power tools (1)

- SMALL METAL PARTS (1)

- Sensors (1)

- Testing equipment (1)