- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- unloading systems

Results for

Unloading systems - Import export

FEMIA INDUSTRIE

France

Right when your products arrive at the plant, receiving, the beginning of the processing process, is a key element in the performance of your production line. Indeed, the receiving hoppers must be adapted to your unloading system and this first step contributes substantially to the smoothing out of the flows in the preparation line. The receiving solutions that we offer are intended for the unloading of the product coming from the field by avoiding losses of raw material, by preserving the integrity of the latter and by ensuring a continuous and controlled flow rate on the line Hoppers – whether underground or not – with a system of elevators, manual load hoppers (…), our range of receiving machines allows us to set up a solution in line with the method of unloading used (truck, bag, tips, containers.)With a concern for preserving our customers’ products, we have developed hoppers that are specifically designed for certain vegetables according to their shapes and weights.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® ECO is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The ECO series is the basic model of the OKTOMAT® emptying stations and is ideally suited for the majority of applications dealing with free-flowing to poorly flowable materials. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable. Due to its pedestal form, the ECO is particularly space-saving in width, the height is individually adjustable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS Classic is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its portal form it is particularly space-saving in depth and the increased tension force allows even high-density materials to be emptied without a problem. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

OKTOMAT® SOS is an emptying station for the automatic emptying of Octabin and BigBags. A pallet jack is enough to move the container under the emptying station. The bulk bags can be completely and trouble-free emptied from above. The OKTOMAT® uses a vibrating suction head and the automatic bag tightening mechanism pulls the foil inlet or BigBag upwards. The material flows towards the middle and is continuously sucked. The SOS series with its full equipment is ideally suited for the majority of applications and difficult tasks. The integrated oscillating systems for foil / BigBag tightener and suction head enable the emptying of free-flowing to heavily bridge-forming materials. Due to its pedestal form, the OKTOMAT® SOS is particularly space-saving in width, the height is individually adjustable. OKTOMAT® emptying stations are easy to use, low maintenance, robust and durable.

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quote

ROLLON GMBH

Germany

Versatile transfer system for metal sheet handling, designed as the main element in a series of presses which eventually combine with load/unload systems. The system features high positioning precision with heavy duty cycles and high dynamics, and is also available for very extended lengths. It manages cantilever loads to keep one side of the series free for operations. The system is driven by a belt with Ω transmission. The Z axes can be placed at different distances, according to the loads. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Ideal automation solutions for loading and unloading of parts on machining centres, presses, measuring stations, etc… Convenient, accurate, repeatable and reliable! The CLA Robot Cell is composed of the following: - A polyarticulated robot or scara with specific grippers - A camera device for part recognition - Automatic camera calibration - Parts loading/unloading system - Protection (cage, mats, detection, etc) - Each application is studied and simulated in order to define the ideal solution - Microplates screening. CLA is a center of expertise of Mitsubishi robots

Request for a quote

FERPLAST SNC

Italy

To be installed at the exit of the packaging machines and welding machines. ROTATING TABLE OF ACCUMULATION WITH STAINLESS STEEL STRUCTURE AND NYLON PLAN The rotary table of accumulation is generally used in the final part of the packaging lines and facilitates the discharge of the packs, facilitating the sampling operations by the operator. The rotating tables with nylon plan are available with a diameter of 800, 1200 or 1400 mm, and are suitable for bottles, cans and products that can overturn in the concave or convex turntables. The flat rotating tables can be equipped with loading systems and automatic unloading and thus be used as "accumulation areas" between an automatic machine and another. Edges and sides nylon version Flat turntable with holding sides, polyethylene plan, useful height of 810 mm and a mechanical speed variator.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

LIS B135L - DIY concrete mixer ideal for small projects Bucket with 2 double kneaders Cast iron rack and pinion reinforced mouth Bearing box on the outside of the bucket unloading system pedal brake

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut, optimize, stock and handle the bars, suitable for mass productions, based on a shear CGS 500, mounted on a mobile frame, with blade of 500 mm (20''), VMT measuring and cutting track to cut the bars to size and unload them on the right or left. In the VMT SUPERFAST version, the roller conveyors and the unloading systems are divided into two parts individually operated. This ensures a much faster working cycle.

Request for a quote

SCHNELL SPA

Italy

IPC 40 is the plant for the production of radius bars with bends in a single, automatic process. It is composed of the radius machine CER 40, the bidirectionalbending machine P 45 PRO and has an unloading system for the completed bars. It is possible to fabricate 2 bars simultaneously in the diameter range between Ø10 mm and Ø 40 mm.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut, optimize, stock and handle the bars, suitable for mass productions, based on a shear CGS 300, mounted on a mobile frame, with blade of 300 mm (12''), VMT measuring and cutting track to cut the bars to size and unload them on the right or left. In the VMT SUPERFAST version, the roller conveyors and the unloading systems are divided into two parts individually operated. This ensures a much faster working cycle.

Request for a quote

ASTRA LT AB

Lithuania

„Astra LT” road tanker is engineered and manufactured in a state-of-the-art facility in Alytus, Lithuania. Close cooperation between our engineers and end users helps us develop modern solutions. We have analysed many existing tankers in the European market and, together with end users, we have carefully studied the advantages and imperfections of present designs. We then have taken that information to develop our model, applying the latest technology to create the new Advanced Road Tanker. Really lightweight. Only 6,130 kg is quite impressive for a 3-section 30 m3 pressure-less tanker equipped with a hygienic/air pressure unloading system. Every element is designed

Request for a quote

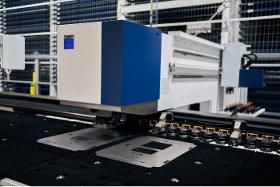

SINOP SMP

Czech Rep.

Technology of CNC punching offers unbeatable accuracy, reliability and productivity. Our CNC punching machines gives us various processing capabilities such as thread forming, profiling and much more. Our machine TruPunch 5000 is equipped with Sheet Master – the automated loading and unloading system enabling the unrivalled process efficiency. Efficient punching of holes and shapes Threading, shape forming and punching of complex contours The active die guarantees scratch-free surface Automatic feeding of metal sheets and unloading of products with automated Sheet Maste Mild steel up to 5 mm, stainless steel up to 4 mm Maximal size of the metal sheet 3000 x 1500 mm

Request for a quote

EUROLASER GMBH

Germany

Loading and unloading during cutting process - increased system duty Easier accessibility of the pieces produced by moving the material support Increasing efficiency by minimising downtime Easy handling Automatic table shift after cutting process possible System is not encapsulated - Robot assembly possible (24/7 - operation) New material is located on the top shuttle table - thereby no material remaining is falling on the new material. Shuttle Table System automatic (STA) Table shift at the touch of a button Process starts automatically after cutting is finished Time saving by optimised processes Minimising supervision of the laser system Additional manual handling possible Snapping table module in after the shuttle process prevents incorrect handlings Of course, the Shuttle Table System is still available as a mere manual version.

Request for a quote

TARET

Poland

The product perfectly eliminates physical effort during all kinds of work on the farm, such as: moving loose materials, transporting seed material or collecting stones from fields. The box is equipped with a manual quick unloading system, a popular tipper.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LVD

Belgium

The FA-L automatic load/unload system is designed to keep pace with today’s high-speed fiber and CO2 laser cutting machines. It can unload a processed sheet and load the next sheet in just 40 seconds. By keeping a continuous, uninterrupted production flow, the system maximizes machine throughput. The FA-L is ideal for large-volume applications with common material type, thickness and size. KEY FEATURES Automated production from stored raw material to stacked finished part Fast loading system Automatic sheet thickness control and automatic sheet separator devices ensure efficient material loading Intuitive touch screen graphical user interface PRODUCTIVITY-ENHANCING OPTIONS Second loading pallet Belt-driven unload system for scratch-free unloading Full integration with an existing warehouse MODELS Available for Sirius Plus, Electra and Phoenix systems

Request for a quote

LVD

Belgium

COMPACT, COST-EFFECTIVE AUTO LOAD/UNLOAD SYSTEM Process work faster with the PA Autoload system. This automatic load/unload device reduces manual worksheet handling by as much as 80% to make punching operations more productive.The PA loads and unloads material from the same side of the machine for space-saving efficiency. High process stability allows unmanned production. KEY FEATURES Reduce manual handling times by up to 80% Full brush table configuration Handles delicate part nests Includes autoload interface PRODUCTIVITY-ENHANCING OPTIONS Auto load ready package allows factory installation or future retrofit MODELS Available for VX, V, M and PX-Series punch presses

Request for a quote

KEDY

Turkey

Manual All controls are made by the operator via the control button. Each crane is controlled by an operator. Semiautomatic H Busbars are an automatic transport system from the unloading area to the loading area. The system is suitable for automatic operation. Transitions between stations are made by operator control. Waiting and immersion times are automatic in the boilers. Automatic operation when necessary, but in case of failure, intervention with external operators, transitions between boilers are made by the operator. Fully Automatic The whole process is controlled from the skada screen. There is no need for an operator at the beginning of the cranes. All boiler chemical controls are made automatically from the skada screen. Transitions between stations are made automatically to unloading stations. It has the possibility of easy maintenance and intervention with remote access. Lifting drive is with chain gear system and it is supported by rollers on the guide rail

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Handling Systems for Handling Printed Circuit Boards JUKI’s handling solution includes a wide range of reliable products to assure the secure handling of printed circuit boards involving SMT manufacturing conveyors; loaders and unloaders; buffers for PCBs; other systems such as turn units, stacker units; customised solutions for individual customer requirements etc. JUKI believes in durability and reliability. Our handling products are suitable for the requirements both of small and large production systems – while providing a highly attractive price performance ratio. Our partner Electro Design has more than 30 years of expertise in the development and manufacturing of handling systems for the electronic industry. In 1987, the company marketed its first conveyor belt and has since sold about 5,000 units to customers worldwide.

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT container blenders are specially designed for gentle product blending and flexible pick up of various containers. The hydraulic clamping system ensures absolutely secure take-up of the blending container. The PLC and recipe-controlled blending process provides optimal adaptation to the blended goods. The Servolift horizontal clamp bar system easily picks up various container sizes or adapters for drums and small containers. The ability to extend the handling functions of lifting, lowering, inverting, pivoting the blender columns provides many applications for the container blender. This is extended through optional installed and auxiliary systems such as automatic feed and unloading, chopping in the blending container, spray system to add liquids to the blended product, prior and follow-on weighing machinery, dosed unloading, NIR systems, etc.. Blend in a closed system Technical description Stainless steel or cGMP-compliant design Take up blending containers which are...

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer discharging device for residual liquid permits emptying residual liquids from reusable bottles. Bottles with large quantities of residual liquid can be fed into the machine via a bypass. Cleaning occurs during continuous material flow. In addition to turning and cleaning, differences in height can be overcome at the same time. Technical data: —Conveyor performance: up to 60,000 units/h —Overhead track: up to 10 m —Difference in height: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid —electrical control system —loading and unloading belts —water lances for cleaning support of the cleated chain

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer depalletizer is an economical alternative to a completely automatic machine. It is used when processing small to mid-sized numbers of items. An individual arrangement of depalletizers lets one person operate several machines. Easy operation allows for a short training period for new personnel. Technical data: —Use of EURO pallets (1200x800 mm) or special sizes (1200x1000 mm) —Pallet height: up to 2250 mm —Pallet weight: up to 1000 kg —Depalletizer performance: up to 64 layers/h for 8 pallets —Independent electrical control system Optional equipment: —Unloading belts —Accessible platform according to customer request

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer head space moistener permits moisting of the cap with the fluid in the container. Machine dimensions depend on the conveyor performance and the desired moisting time. Moisting occurs during continuous material flow. The machine is a space-saving solution due to the vertical moisting track. The design permits products to run through the machine without turning process, if necessary. Technical data: —Conveying performance: up to 60,000 units/h —Moisting path: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid with maintenance doors —electrical control system —loading and unloading belts

Request for a quote

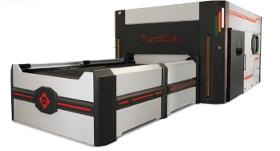

LASER ISSE LASER TECHNOLOGIES

Turkey

3000x1500mm / 4000x2000mm / 6000x2000mm Standard size Cutting Bed Fiber & Disk Laser Option Laser Power Range between 1kW-12kW Autofocus – Manual Focus Cutting Head Options Ramping Shuttle Table Advanded TurcCut New Generation HMI Metalix CAD/CAM Nesting Edge Detection Sensor Robotic Unloading Option Patented Back Reflection Sensor AVAILABLE FEATURES Robotic Integration Auto – Feeder Solutions Gantry System Unloading Laser Marking Unit Custom Size Cutting Bed Monitoring Camera Integration Existing Production Line I/O Connection (Ethernet)

Request for a quote

NORMIT

Slovakia

Tilting pan with indirect heating and integrated stirrer is designed for frying, steaming, cooking vegetables, fish, meat, sauces, pasta with constant stirring, eliminating the risk of burning or uneven heat treatment. Processes: •Stewing •Cooking •Evaporation •Frying •Deep frying Advantages: • Equipped with a duplicator and electric heating elements. • Fast heating and high thermal efficiency. • Reinforced stirrer with Teflon scraper, which in continuous mode cleans not only the entire bottom, but also the walls of the pan, ensuring a perfect result. • Tilt ensures complete unloading of the working container. • Made of high-quality food-grade stainless steel AISI304 or AISI316L. • Easily sanitizable • No dead zones. Technical specification: Working volume up to 130l Recommended Termooil heating Frying temperature up to 160 C Stirring device: yes Product unloading type: electric driven tilt system Dimensions (LxHxW): 1800x1900x1400 mm Weight: 350 kg

Request for a quoteResults for

Unloading systems - Import exportNumber of results

34 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (4)

- Plastics - machines and material for industry (4)

- Conveyor belts (3)

- Industrial cutting machine tools (3)

- Automation - systems and equipment (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Broaching - machine tools (1)

- Broaching - steels and metals (1)

- Buckets and grabs, crane (1)

- Catering - machinery and equipment (1)

- Compactors and crushers (1)

- Conveyor systems (1)

- ELECTRICAL SYSTEMS (1)

- Goods lifts (1)

- Handling - Machines & Equipment (1)

- Harvesting machinery and equipment (1)

- Industrial tools (1)

- Internal transport systems (1)

- Steam polishers (1)

- Turntables (1)