- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- union nut

Results for

Union nut - Import export

CIC - KLAUS CZERWONKA

Germany

Made of nickel-plated brass with union nut

Request for a quote

FLUX-GERÄTE GMBH

Germany

The horizontally installed, compact container pump MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top. It is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. Benefits: - Can be used where ceilings are low - Allows pumping directly from floor-level outlets, even when containers are stacked - Significantly higher flow rate and pressure compared to draining by gravity - Minimal space requirement - Simple disconnection from IBC with union nut - Delivery against closed valve (e.g. hand nozzle, flap valve etc.) possible - Suitable for use in hazardous areas zone 1

Request for a quote

FLUX-GERÄTE GMBH

Germany

The pump-kit MINIFLUX is designed for emptying IBCs via their floor-level outlet. Designed as an alternative to a vertical pump, the MINIFLUX can be used when an IBC is not accessible from the top. It is suitable for applications when gravity draining via the outlet tap is insufficient e.g. rapid dispensing or transfer to another container in a higher location. Power can ideally be provided by a commutator or compressed air motor. Product attributes: - For pumping out of IBCs directly from the outlet (with standard S60 x 6 thread) - Simple connection of the pump to the outlet by union nut - Compact design - Can be dismantled into two parts via clamp - Low overall weight of 1.2 kg - No need to mount pump to top of container - Does not require access to the container from above - Ideally combined with commutator motor or compressed-air motor Benefits: - Can be used where ceilings are low - Allows pumping directly from floor-level outlets, even when containers are stacked

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ C67 HPW CleanStar ultra pure 2/2-way diaphragm valve is manually operated. All medium wetted parts are made of PVDF or PTFE. —High purity due to cleanroom manufacturing —High Flow version —High flow rates —Minimal deadleg —Optional flow direction —Also available as T valve —The valve is available with ECTFE union nut as an option. Thus you achieve: brief equipment rinsing times, clearly improved Kv values (High Flow), high "MTBF" and reduced costs

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ C60 CleanStar ultra pure 2/2-way diaphragm valve has a plastic piston actuator and is pneumatically operated. A stroke limiter and an optical position indicator are integrated as standard. All medium wetted parts are made of PVDF or PTFE. —High purity due to cleanroom manufacturing —High Flow version —High flow rates —Minimal deadleg —Optional flow direction —Also available as T valve —The valve is available with ECTFE union nut as an option. Thus you achieve: brief equipment rinsing times, clearly improved Kv values (High Flow), high "MTBF" and reduced costs

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

Fittings Our manufacturing site in Switzerland produces over 100 different types of fitting under cleanroom conditions in compliance with DIN 16901-140. The fitting bodies are made of PFA, while the union nuts are made of PFA, PVDF or CPFA. We stock all the connections available on the market too. Emmen cleanroom plant GEMÜ has be producing valves and fittings at its new cleanroom plant in Emmen (Canton of Lucerne, Switzerland) since September 2012. A state-of-the-art manufacturing and assembly facility was built here when, thanks to commercial success, the capacity of our site in Rotkreuz could no longer keep up with demand. When planning and developing the facility, designers focused on creating a contemporary quality management system that is fit for the future. The result is that product and production quality are ensured, for example, by using specific inspected raw materials and through audits carried out by customers and official bodies.

Request for a quote

BELLUNO PLAST S.R.L.

Italy

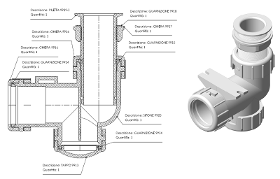

9921 Elbow kit 1 inch gas consisting of the following elements: 9919/1 1-inch gas drain 9918 gasket for 1-inch gas drain 9917 ring nut for 1 inch gas drain 9916 union nut (2 pcs) 9914 sealing gasket diameter 32 9915 sealing gasket dm. 30 9921/1 elbow connection

Request for a quote

BELLUNO PLAST S.R.L.

Italy

9922 1-inch gas T-kit consisting of the following elements: 9919/1 1-inch gas drain 9917 ring nut for 1 inch gas drain 9918 gasket for 1-inch gas drain 9916 union nut (3 pcs) 9914 sealing gasket diameter 32 (2 pcs) 9915 sealing gasket dm. 30 9922/1 1-inch gas T-piece

Request for a quote

BELLUNO PLAST S.R.L.

Italy

9910 - 1 inch gas siphon kit consisting of the following elements: 9919/1 1" drain 9918 gasket for 1" drain 9917 1"drain fixing ring nut 9916 union nut (2 pcs) 9914 sealing gasket diameter 32 (2 pieces) 9915 sealing gasket dm. 30 9920 1" siphon 9913 Inspection plug

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

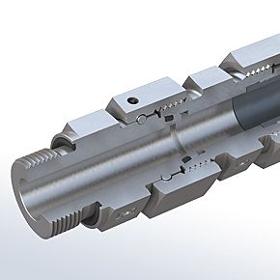

Due to the 24° taper (with o-rings) located on the fitting body itself, STAUFF Connect Tube Fittings with 24° Taper / O-Ring (DKO) represent a logical further development of traditionally available adjustable standpipe tube fittings with factory-assembled cutting rings and union nuts. The retention function is assured by a special swivel nut with a wire-pin located in a groove, which is factory-assembled by the manufacturer. The embedded o-ring on the 24° taper ensures a high level of protection against leakage. Thanks to the large number of available types and designs, almost all common types and combinations of adjustable fittings can be implemented. With regards to their dimensioning and general design, STAUFF Connect Tube Fittings with 24° Taper / O-Ring (DKO) fully comply with the latest versions of the ISO 8434-1 standard. They are thus completely interchangeable with conventional adjustable standpipe tube fittings.

Request for a quote

EISELE GMBH

Germany

- One interface for compressed air, gases, liquids, electrical and electronic signals - Fits to Eisele Adaptive insets - Can be assembled as bulkhead - Material Al nickel-plated or stainless steel - Temperature range -20 to +120 °C - Working pressure range -0,8 to 0 bar or 0 to 24 - Up to max. 14 connections

Request for a quote

SANHA GMBH & CO. KG

Germany

The innovative SANHA installation system NiroTherm® combines high-quality NiroTherm® press fittings with a black sealing ring made from EPDM (=ethylene propylene diem rubber) and NiroTherm® stainless steel system tubes. The system is produced from the material 1.4301 (AISI 304). Due to the well-known corrosion resistance of stainless steel, NiroTherm® offers installers therefore a real alternative compared to conventional steels when it comes to closed systems in humid atmospheres such as screed. Since it needs considerably less isolation against humidity*, the installation is faster and labour costs accordingly lower. In addition to the system description, NiroTherm® system press fittings are marked on the outside with a red dot. * This does not affect thermal insulation necessitated by national energy efficiency laws. NiroTherm® system pipe, material no. 1.4301, reduced wall thickness, in 6 m lengths, for cooling, compressed air, heating and industrial applications

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Manufacture by machining is battling against the rising cost of materials and long machining times. That's why many companies are finding our forming process for hollow parts of increasing interest. We have other forming options for machine-finishing in-house. Our cold-forming process is distinctive – including for thin-walled hollow parts because of: rolled (chip-free manufacture) external threads suitable surfaces for maximum corrosion requirements Some examples of Conform® hollow parts and nuts: sensor housing union nuts for hydraulic, brake and fuel lines clinch nuts

Request for a quoteResults for

Union nut - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (6)

- Drainage systems and equipment (3)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Portable electrical pumps (2)

- Nuts and bolts (1)

- Clutches (1)

- Connectors, plumbing (1)

- Mechanical transmission - components (1)

- Nuts (1)

- Temperature sensing devices (1)

- Vehicles - mechanical components and parts (1)