- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- torque sensors

Results for

Torque sensors - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This torque sensor is qualified for static and dynamic measurements on non-rotary applications. Further the measurement of reaction torques on rotating machine parts is possible. Especially the torque sensors with flanges are preferred. They are mounted between motor and stator, e.g. in agitator drives. This enables a maintenancefree torque measurement. For individual measuring tasks the design of our torque sensors can be adapted to the customer’s installation conditions. More application examples: Test structures in the field of precision mechanics Determination of friction torques Acquisition of breakage moments on screw caps The design has been optimized regarding overall length, weight and volume, so that axial forces up to relatively high limit values and bending moments of up to 20 % of the measuring range have only a small effect to the influence of the measuring element.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

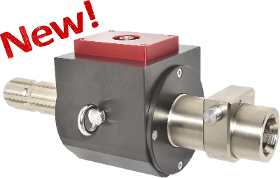

LOAD CELL AND TORQUE SENSOR – X/Y/Z - Model 8565 In robotics and automation engineering, the requirements for precise, tactile handling are constantly increasing. The robust 8565 multi-axis sensor with its low crosstalk enables you to monitor and evaluate your process at any time, regardless of the sensor’s orientation. With just one sensor, you can obtain accurate three-dimensional load information. Its six independent outputs let you selectively evaluate the direction of action of the loads (axial force [Fz] / lateral forces [Fx/Fy] / torque [Mz] / bending moment [Mx/My]). Thanks to its compact design and adaptation via the standardized robot flange in accordance with DIN ISO 9049-1, the sensor can be integrated into many applications quickly and easily. When the slightest deviations are detected in your fast-moving and complex production processes, you can intervene immediately to make adjustments. This helps to prevent faulty parts and reduce manufacturing costs.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The compact torque sensor model 8655 with standard square is contactless constructed. The torque is recorded by the torsion of the shaft using the strain gage principle. Thanks to the inductive and optical transmission of the signals, the sensor is maintenance-free, the signals are digitized directly on the shaft and made available by the evaluation electronics as a voltage signal or via USB. The direction of rotation can be seen from the potential of the output voltage, clockwise rotation corresponds to positive output voltage, counterclockwise rotation the voltage level is negative. The standard square enables simple integration into existing systems or devices, additional components such as couplings are not require. To record the speed and angle of rotation, the sensor can optionally be equipped with an incremental disc with 400 increments. This speed / angle signal is available as a TTL output signal.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The very short torque sensor model 8656 is contactless constructed. The torque is recorded by the torsion of the shaft using the strain gauge principle. Thanks to the inductive and optical transmission of the signals, the sensor is maintenance-free, the signals are digitized directly on the shaft and made available by the evaluation electronics as a voltage signal or via USB. Thanks to the high-quality, up to 10,000 rpm is possible. The direction of rotation can be seen from the potential of the output voltage, clockwise rotation corresponds to positive output voltage, counterclockwise rotation the voltage level is negative. The shaft is equipped with keyways in every measuring range, matching keys are included. If a key connection is not required, the key can be omitted. The torque is matched with suitable couplings, we recommend model 8690, safely transmitted.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The Digimes Universel is a 5 KHz carrier current bridge for resistive, inductive or differential transformer transducers connected in full or half bridge. The sensitivity is adjustable by the user between 2 mV/V and 100 mV/V according to six measuring ranges. Gain and offset can be adjusted with potentiometers to allow calibration of the sensor. There is also the Digimes Compact, dedicated to one sensor.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor is designed for both static and dynamic measurements on non-rotating parts. The 10mm diameter throughhole can be used to feed parts such as cables or Bowden cables through the sensor. The mounting flanges contain threaded holes and through-holes so that the sensor can be fitted at either end. With no rotating parts, this sensor needs no maintenance when used correctly. The modular design of this strain-gage sensor allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function. With the USB option, in addition to the voltage output, the measurement function is available via USB as well.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

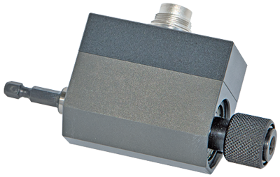

This high-precision torque sensor can be used to perform both static and dynamic measurements on non-rotating parts. The internal and external square drive design make this sensor especially easy to fit in existing or new screw-fitting applications. Quality assurance and monitoring of screw-fastening tools are just two applications that can take full advantage of sensor features such as USB port, built-in amplifier and side-load absorbing bearings. With no rotating parts, this sensor needs no maintenance when used correctly. Available accessories include mounting brackets and flange adapters, which enable quick, easy and practical integration of the sensor into existing or newly developed setups and test benches. The strain-gauge based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The CLA TSF-000 through TSF-5 are bidirectional, inductive type torque sensors. The measurement system is composed of an axis mounted on flexible pivots with cruciform springs allowing frictionless torque measurement. The axis rotation angle measurement, which is proportional to the measured torque, is performed via an inductive displacement sensor with carrier frequency. The small rotation angle, approximately 1° for all measurement range, allows very good linearity and negligible hysteresis.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The CLA LC-01 and LC-1 are bidirectional, inductive type force sensors. The measurement system is composed of a displacement transducer which mobile core is linked to two leaf copper beryllium springs. The spring flexion measurement, which is proportional to the force to be measured, is performed by inductive sensor with carrier frequency. The measurement shaft is interchangeable, allowing the use of special shaft.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

The CLA SC-002 is bidirectional, resistive type force sensor. The measurement system is composed of a semiconductor strain gage. The measurement shaft is made of a 0.5mm diameter axis with a positioning notch for calibration and measurement. The design of that sensor is specially made for a high resonance frequency.

Request for a quote

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

In order to measure torque and force, a large range of sensors is available. All these sensors are bidirectional, inductive or resistive type with a good linearity and negligible hysteresis. These sensors allow to measure torque less than 1 uNm and up to 1 Nm.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

1800 Nm max. on 1 3/8“ shaft according to ISO 500-3:2014 Type 1 On request also available: 1800 Nm max. on 1 3/8“ shaft according to ISO 500-3:2014 Type 2 2500 Nm max. on 1 3/4“ shafts according to ISO 500-3:2014 Type 3 contactless signal transmission built-in measuring amplifier rotation angle measurement (optional) extended EMC strength adjustable output level of rpm and angle signal (5V-24V) Frequency output 10kHz ±5kHz large input voltage range (10-28,8V) strain gauge technology robust design for use in field applications IP67 easy installation accurate results (0.2% accuracy) The torque sensor DRVZ provides a precise measurement of torque and angle of rotation when testing systems that are driven by PTO shafts, such as a tractor gearbox.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

No service needed because of contactless data acquisition High accuracy due to frequency modulation and strain gage technology Single power supply High noise immunity due to amplified active signal integrated sensor-detection chip for use with GMV2 analyzer automotive industry test benches assembly applications pulsed tools hexagonal drive 7 Measurement range from ± 0 - 1 Nm up to ± 0 - 20 Nm optionally with angle measurement

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Simultaneous speed / torque display universally applicable sufficient for many measuring tasks 11 torque range from ± 0 - 0,5 Nm to ± 0 - 1000 Nm Very short Broad input voltage range Current output and voltage output Measurement accuracy: ≤ 0,5% of full scale Torque ranges from 0,5 to 1000 Nm Contactless transfer of measurement signal Proven strain gage technology Integrated signal amplifier Single power supply Multipurpose use Simultaneous speed/torque indication 4-segment display with sign Peak mode (clockwise only) Indication area on LCD display 30 x 11 mm Speed indication updated 1x sample/second Torque updated 1,000 samples/second

Request for a quote

ETH MESSTECHNIK GMBH

Germany

11 torque range from ± 0 - 0,5 Nm to ± 0 - 1000 Nm Low cost. Very short. Broad input voltage range. Current output and voltage output. Optional speed measurement. Measurement accuracy: ≤ 0,5% of full scale. Torque ranges from 0,5 to 1000 Nm. Multipurpose use. Contactless transfer of measurement signal. Integrated signal amplifier. Proven strain gage technology. Single power supply.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

11 torque range from ± 0 - 0,5 Nm to ± 0 - 1000 Nm current and voltage output measurement accuracy ≤ 0.25% contactless signal transmission proven strain gauge technology built-in signal amplifier simple power supply universally applicable RPM measurement optional The new features: more versatile mounting options torsion shaft stainless mistake-proof installation oriented mounting large coupling selection The torque sensors of the DRBL series are a further development of our DRBK series and are suitable for use in the laboratory and for industrial environments with their compact dimensions and diverse mounting options. A factory calibration certificate with 25% increments (left, right) is included in the scope of delivery. The non-contact transmission of the measurement signal and the supply energy enables low-wear and m aintenance-free continuous operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGTROL

Switzerland

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs. Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup. more info www.magtrol.com

Request for a quote

MAGTROL

Switzerland

Magtrol offers three types of torque transducers for dynamic torque and speed measurement. All three transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits most notably that no electronic components rotate during operation. Each model has an integrated conditioning electronic module providing a 0 to ±10 VDC torque output and an open collector speed output. Magtrol’s Torque Transducers are very reliable, providing high overload protection, excellent long-term stability and high noise immunity.

Request for a quote

SENSY S.A.

Belgium

General purpose, noncontact rotary torque sensors with flanges or PTO shaft. o Bidirectional o Measurement range up to 5 kN·m o Rotating speed up to 3600 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table) Torque limit 5000 N·m

Request for a quote

SENSY S.A.

Belgium

General purpose, high capacity noncontact rotary torque sensors. o Bidirectional o Measurement range up to 25 kN·m (>25 kN·m on request) o Rotating speed up to 8000 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

SENSY S.A.

Belgium

General purpose, high rotating speed, noncontact rotary torque sensors with square or round shaft. o Bidirectional o Maintenance free o Round or square shafts (see drawing) o Measurement range up to 100 N·m o Max. rotating speed Square shaft 5 000 rpm Round shaft 10 000 rpm o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

SENSY S.A.

Belgium

General purpose, lowcost, noncontact rotary torque sensors with square or round shaft. o Bidirectional o Cost effective solution o Measurement range up to 500 N·m o Rotating speed up to 5000 rpm o Round or square shafts (see drawing) o Integrated signal conditioning o Analogue output signal (see Wiring table)

Request for a quote

DAVALL GEARS LTD.

United Kingdom

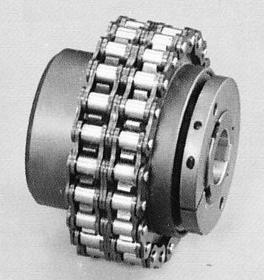

Davall DSG supply torque limiters

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The latest technology Datum Electronics Series non-contact rotary Torque Sensors have been designed to fit with most applications where the measurement of accurate rotary torque and power measurements are required. The M425 Rotary Torque Sensor fits in line with the drive train or test bed, using standard key-way shafts. The Datum M425 Rotary Torque Transducer represents a quantum leap forward for anyone looking to measure torque and power with high accuracy and repeatability using up to 24 bit resolution. The M425 torque sensors give the customer control over their tests with torque sample rates selectable at any time from 1sps up to 4000sps as standard. With rpm measurement based on up to 30 pulses per revolution, the M425 is now the complete torque transducer for measuring torque and power on any rotating shaft. When paired with the Datum Universal Interface (DUI), the M425 Torque Sensor gives customers a ... ** Click for more **

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

FF410 Static Torque Transducer provides a competitive option within the reaction transducer market Static Torque Sensor/Transducer FF410The Datum Electronics Series 410 Static torque sensor was developed following developments of our FF420 series of rotary torque transducers. The same basic shaft components and strain gauge technology have been applied to our 410 Reaction transducer range providing a competitive option within the static transducer market. SERIES 410 REACTION TORQUE TRANSDUCER - Flange Mounted static transducer - Flange torque transducer match standard DIN Flanges - Ideal design for easy fitting to test rigs and drive systems - No bearings with lightweight hollow shaft unit - Unique design offers high torsional stiffness model - Standard 410 reaction torque sensor range available from 250Nm-10,000Nm - Strain gauge output compatible with Datum Type310, Type324, Type 300 Indicators. ** Click for more **

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The Datum Electronics Series RS425 bearingless torque transducer has been designed to fit easily in line with any drive-train or test rig, using either a spline or key-way shaft. We are able to modify the ends of the transducer to best suit your requirements, and can even design bespoke ends to fit. This type of transducer has many advantages over other torque systems including zero bearing friction, high speed and high torque applications. The Series 425 Torque Transducers can be adapted to replace exiting drive shafts on test rigs and in drive lines, this saves the time and cost of designing in special couplings and intermediate shafts to accommodate conventional transducers. By measuring torque on longer drive shaft you prove the accuracy of the measurement and its tolerance to offset loads. Using a direct replacement with a lightweight rotor the dynamics of the driveline are maintained. ** Click for more **

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The latest technology Datum Electronics Series FF425 non-contact rotary torque transducer and FF410 torque sensors have been designed to fit easily inline with any drive train or test rig using standard DIN size couplings. With Flange couplings at either end of the torque transducer, it has many advantages over other torque measurement systems. FF425 Non-Contact Torque Transducers and Sensors The FF425 rotary torque transducer utilises a strain gauged shaft for accurate and reliable torque measurement and a set of rotating on shaft conditioning electronics, the digital signals are transmitted to the non-rotating part of the system or stator providing a reliable and highly accurate torque measurement solution. ** Click for more **

Request for a quote

GEDORE-TORQUE

United Kingdom

Gedore-Torque manufacturer of torque screwdrivers, a selection of types and uses. Speak to our sales team to find the torque tool you need 01483 894476

Request for a quoteResults for

Torque sensors - Import exportNumber of results

60 ProductsCompany type

Category

- Sensors (26)

- Measurement and control instruments (16)

- Automation - systems and equipment (6)

- Measurement and regulation equipment and instruments - pressure (6)

- Measurement - Equipment & Instruments (3)

- Precision measuring instruments (2)

- Robotics (2)

- Testing equipment (1)

- Couplings, mechanical (1)

- Electric motors and parts (1)

- Medical and surgical instruments (1)

- Welding robots (1)