- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- torque measuring shafts

Results for

Torque measuring shafts - Import export

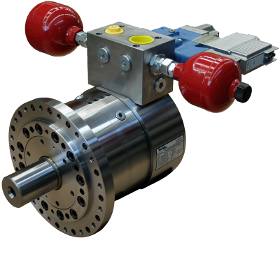

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

Thanks to a wide range of accessories, Hense operators can be individually configured for a wide variety of applications and optimally matched to the function of the overall system. To ensure perfect and safe operation, we are on hand to help you select and optimally coordinate all components.Servo valves, proportional valves and switching valves with different nominal sizes Pulsation damper for smoothing vibrations and uneven flow rates Subplates for positioning valves and pulsation accumulators close to the motor High-resolution rotation angle sensors that are coupled directly to the swivel motor shaft by means of a torsionally rigid coupling Pressure sensors Torque measuring shafts or reference torque measuring disks Clamping sets, shrink disks or profiled hubs for torque transmission Torsionally rigid couplings for reliable torque transmission with simultaneous shaft displacement Angled flanges for mounting the swivel motors parallel to the axis

Request for a quote

MAGTROL

Switzerland

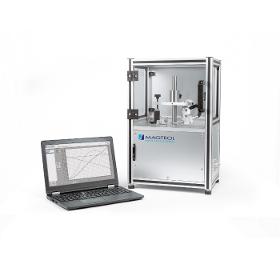

MSD Mega Speed Dynamometer is the latest Magtrol innovation in the very high-speed motor and system testing. Challenged by its numerous customers in the Dental and Surgical field, Magtrol is pushing the limit to a level which was never reached. The braking effect is based on Eddy-Current induced on an aluminum disc directly mounted on the DUT (Device Under Test) shaft. Torque is measured frictionless by a 20 mN·m Reaction Torque Sensor having a resolution of 0.01 mN·m. Due to the thermal effect on the disc, the Mega Speed Dynamometer is not suitable for endurance testing, but can be used to generate a fast curve or perform point to point testing. An infrared sensor monitors the temperature of the disc and stops the test in case of overheating. The disc can be designed and sized according to the motor parameters. The system is contactless therefore alignment is not critical and the inertia is very low (no friction, no residual or drag torque).... more info: www.magtrol.com

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

We offer our customers the leasing of our test bays for testing your machines and systems.The above-mentioned machines can also be coupled in sets of three so that even higher outputs are possible. At LDW we also have several DC machines with other speed ranges and lower outputs. We also have three-phase load machines with speed ranges from 750 to 3,000 1/min at an output range of 1,400 to 3,000 kW. Our largest measurement shaft has a torque of 5,000 Nm (accuracy class <1%). We usually verify the torque via a DC-machine. We have several DC machines with speed ranges of 100 to 6000 1/min in the test bay (depending on requirements) at an output range from 100 to 1,500 kWThe maximum torque of our largest measuring shaft is 5,000 Nm (accuracy class <1%), we usually verify the torque via a DC-machine. Depending on the specific needs we have several DC-machines with speed ranges from 100 to 6,000 rpm and outputs from 100 to 1,500 kW.

Request for a quote

DATUM ELECTRONICS LTD

United Kingdom

The Datum Electronics Series RS425 bearingless torque transducer has been designed to fit easily in line with any drive-train or test rig, using either a spline or key-way shaft. We are able to modify the ends of the transducer to best suit your requirements, and can even design bespoke ends to fit. This type of transducer has many advantages over other torque systems including zero bearing friction, high speed and high torque applications. The Series 425 Torque Transducers can be adapted to replace exiting drive shafts on test rigs and in drive lines, this saves the time and cost of designing in special couplings and intermediate shafts to accommodate conventional transducers. By measuring torque on longer drive shaft you prove the accuracy of the measurement and its tolerance to offset loads. Using a direct replacement with a lightweight rotor the dynamics of the driveline are maintained. ** Click for more **

Request for a quote

MAGTROL

Switzerland

Magtrol’s TS In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0VDC to ±5VDC (±10VDC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TSSeries sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights allow a visual check of the sensor status by color code. The sensor is powered by 24VDC (12-32VDC) through its connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGTROL

Switzerland

Magtrol’s Model 3411 Torque Display is designed for use with all Magtrol TS, TM, TMHS, TMB and TF Torque Transducers. This easy-to-use device powers the transducer and utilizes high speed processing to display torque, speed and mechanical power. It includes a tare function to help offset any slight residuals caused by couplings or suspended loads. The 3411 may also be used with any torque sensors requiring 24 V DC power (500 mA max.) with ± 5 V DC torque output (± 10 V DC max.) and open collector, TTL or CMOS output for the speed signal.

Request for a quote

MAGTROL

Switzerland

Magtrol offers three types of torque transducers for dynamic torque and speed measurement. All three transducer models employ our unique non-contact differential transformer torque measuring technology. This measuring technology offers many benefits most notably that no electronic components rotate during operation. Each model has an integrated conditioning electronic module providing a 0 to ±10 VDC torque output and an open collector speed output. Magtrol’s Torque Transducers are very reliable, providing high overload protection, excellent long-term stability and high noise immunity.

Request for a quote

TEST GMBH

Germany

TesT electrical torque transducers are available as static reaction sensors and with rotary axle for dynamic applications. The requirements of our customers to precise, durable devices for industrial applications are fulfilled. They are easy to handle, from high quality and long life span. Other dimensions, measuring ranges and executions are available on request. TesT delivers all electric force and torque transducers with TEDS chips (TEDS = Transducer Electronic Data Sheet nach IEEE 1451.4). The electronic units of the model 813 and the TesTController 850-USB may recognize sensors equipped with TEDS chips, read their properties and calibration data, and automatically calibrate them. Thus, these electronic units operate with dozens of different sensors, so that a complex recalibration is not required.

Request for a quoteResults for

Torque measuring shafts - Import exportNumber of results

9 ProductsCountries

Company type