- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool changer

Results for

Tool changer - Import export

MECANUMERIC

France

Automatic static or rotative tool changer and cutting tool measurement sensor. Possibility of housing with automatic opening/closing. Subject to the machine configuration / chosen options. Online sales on Meca-line site here

Request for a quote

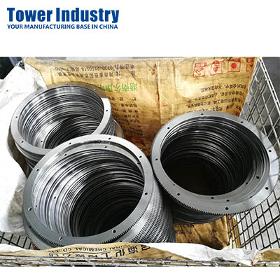

NINGBO TOWER INDUSTRY CO.,LTD

China

We are very suitable for the production DIA 300~1000 mm Ring Gear/ Flywheel. Please feel free to send us your inquiry.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quote

SAMSYS GMBH

Germany

The Quick Changer system enables quick and easy tool change. It has a low weight, a low installation height and is designed for a payload of up to 20 kg. It is patented, reliable and equipped with a user-friendly connection mechanism. Particularly secure locking structure and locking springs. The Quick Changer system is a unique product and ideal for all collaborative robotic applications. The Quick Changer is the easiest and fastest tool changer. Simply everything you need in one package. Not only suitable for OnRobot products. It can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example is the use of existing tools. These can also be equipped with OnRobot’s quick change system. The Quick Changer is alternatively also available as Dual Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

SAMSYS GMBH

Germany

Since the vacuum gripper VG10 does not require a compressor or an air supply, it is a compact and easy to move solution. This makes your production line more flexible and saves maintenance costs. It has flexible arms and an adjustable vacuum. This allows the VG10 to handle different objects in many different sizes. Furthermore, your efficiency is further increased because it is a double gripper. This means you can control the right and left side of the vacuum gripper independently of each other. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments. In addition, there are many third party suction cup attachments on the market to suit any application.

Request for a quote

SAMSYS GMBH

Germany

Do you want to use the OnRobot grippers as double grippers? The Dual Quick Changer double gripper system allows the use of different OnRobot gripping tools in one pass. With this innovative solution, you can use two RG2 grippers or one RG6 gripper with a VG10 – it’s up to you. Switch quickly and seamlessly between our tools with the Dual Quick Changer to maximize the utilization of your robots. With the Dual Quick Changer, throughput times can be accelerated and thus the productivity of your plant increased. Not only suitable for OnRobot products. The DUAL Quick Changer can also be combined with tools from other manufacturers. It can also be used for own constructions. Another example are existing tools, which can also be equipped with the OnRobot quick-change system. The Dual Quick Changer is the alternative to the Quick Changer. This makes it easy to install two tools on one robot arm.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PERFECTLY EQUIPPED FOR EVERY TASK! - The TFZ series offers intelligent solutions from A to Z. STABILITY AND HIGHEST PRECISION DO NOT COME FROM ABOUT BY CHANCE. - Static and dynamic optimization of the components in the power flow - Permanent dimensional accuracy and prevention of tolerance overlap - Minimum distance between pivot bearing and tool center point (TCP) WE KNOW WHAT IS IMPORTANT WHEN IT COMES TO OPERATION AND MAINTENANCE. - Easy crane loading thanks to simultaneous opening of the front and roof doors - Generous sliding doors to the work area - Additional viewing window - Tool magazine & tool rack arranged internally for quick changeover | optional: external & automatic tool changer - User-friendly service access TRUST IS GOOD, CONTROL IS BETTER! - Guarantee of professional machining, long tool life and prevention of accidents & breakdowns - Precise process monitoring during machining

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Safe and as fast as possible – those are the crucial prerequisites that modern tool changers need to satisfy. HUBTEX tool changers with load capacities of up to 65 tonnes help to reduce the changing times for pressing and stamping tools and so improve production efficiency. The compact running gear also allows for extremely low entrance heights underneath machinery. Load capacities up to 65,0 t Tool platform with lift hights up to 3000 mm

Request for a quote

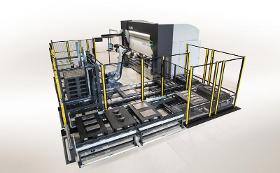

LVD

Belgium

Ulti-Form takes automated bending a step forward with a ToolCell-inspired automated tool changing press brake using a built-in tooling warehouse and equipped with Easy-Form® Laser adaptive bending technology. Programming for both the press brake and robot is handled offline with no robot teaching needed. An auto-adaptive robot gripper designed by LVD automatically adjusts to the workpiece size, allowing different part geometries to be processed without a gripper change. KEY FEATURES Automated tool changer press brake reduces setup time Easy-Form® Laser adaptive bending technology ensures part accuracy KUKA robot and press brake work in synergy to minimize changeover time Programming is handled completely offline, no robot teaching Auto-adapting, universal gripper handles part sizes from 50 x 100 mm up to 1200 x 800 mm High productivity in a compact space, including three input pallets and output zone for up to 10 pallets Automated pallet dispenser and conveyor

Request for a quote

LVD

Belgium

Punch, bend, tap and form all on a single machine. The PX-Series punch press offers the ultimate in flexible production to handle even complex, three-dimensional parts. Its tool changer design features all-tool rotation – each tool is able to rotate a full 360 degrees. With a capacity of up to 200 tools, the ability to use any tool at any angle anywhere on the sheet, and the ability to form flanges up to 75 mm high, the PX-Series machine offers complete versatility. KEY FEATURES Single punch head system with retractable die and all tool rotation design 20 indexable tool stations Accepts 5- or 10-station indexable multi-tool T-style tooling compatible Three fully programmable and re-locatable work clamps Energy Reduction System minimizes power consumption Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute Integrated TOUCH-P control is intuitive and simple to use PERFORMANCE-ENHANCING OPTIONS

Request for a quote

INO MACHINERY

Turkey

ino XP 9000 is a real 5 axis CNC Profile Machining Center working on X-Y-Z-A-C axis independently. Thanks to the CNC controller unit it is possible to make any routing, drilling, milling, notching and cutting operations on the profile pieces in any angle and any position. The machine has a standard size of 7.5 meters and optionally 9.5 meters and 11.2 meters. The pneumatic profile holding clamps are moved by the C column itself and positioned according to the placed that are read from the Profile Machining Software to prevent from collision and for the best grip of the profile piece. The Bi-Rotary head can tilt in A axis +/- 180 degrees and in C axis +/- 325 degrees with the spindle attached 12.0 kW 24.000 rpm with HSK-F63 tool holders. The machine has a tool changer magazine of 10 positions and 1 for the notching and cutting blade. The blades that can be attached on the machine varies from 120 mm to 500 mm max.

Request for a quote

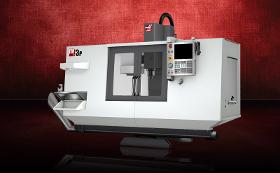

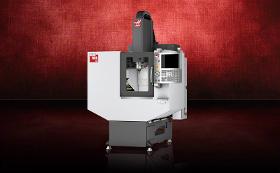

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 40" x 20" x 16" (1016 x 508 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-3P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

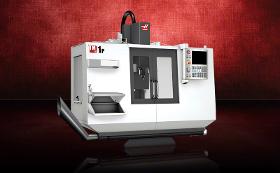

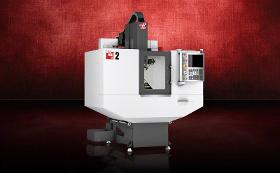

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 40" x 16" x 16" (1016 x 406 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-2P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

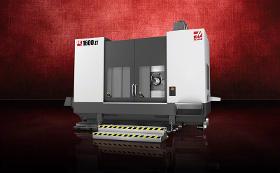

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Toolroom Mill with Tool Changer; 30" x 12" x 16" (762 x 305 x 406 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, full enclosure, 10-station automatic tool changer, Visual Programming System, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port and 20-gallon (76 liter) flood coolant system. TM-1P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Gantry Router; 145" x 85" x 11" (3683 x 2159 x 279 mm), 40 taper, 15 hp (11.2 kW) vector drive, 8100 rpm, 10-pocket automatic tool changer, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. GR-712 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Gantry Router; 121" x 61" x 11" (3073 x 1549 x 279 mm), 40 taper, 15 hp (11.2 kW) vector drive, 8100 rpm, 10-pocket automatic tool changer, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. GR-510 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center for Education; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 4000 rpm, 300 ipm rapids, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor, and USB port. Does not include a tool changer or coolant pump. Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 20" x 16" x 14" (508 x 406 x 356 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 20-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, memory lock keyswitch, USB port and work light. MINIMILL2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 7.5 hp (5.6 kW) vector drive, 6000 rpm, 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, memory lock keyswitch, 15" color LCD monitor and USB port. MINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

5-Axis Horizontal Machining Center; 64" x 50" x 40" (1626 x 1270 x 1016 mm), with integrated B-axis rotary platter mounted with a subplate and HRT310 A-axis rotary table; 50-taper geared-head, 30 hp (22.4 kW) vector drive, 7500 rpm, 30+1 side-mount tool changer; includes 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping, spindle orientation, macros, coordinate rotation & scaling, Wireless Intuitive Probing System, power-failure detection module, and color remote jog handle. Includes enclosure, coolant system and chip augers. Anchor kit required for installation. Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Horizontal Machining Center; 64" x 50" x 40" (1626 x 1270 x 1016 mm), 50-taper geared-head, 30 hp (22.4 kW) vector drive, 7500 rpm, 30+1 side-mount tool changer; includes 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping, power-failure detection module and color remote jog handle. Includes enclosure, coolant system and chip augers. Anchor kit required for installation. EC-1600ZT Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Horizontal Machining Center; 64" x 50" x 32" (1626 x 1270 x 813 mm), 50-taper geared-head, 30 hp (22.4 kW) vector drive, 7500 rpm, 30+1 side-mount tool changer; includes 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping, power-failure detection module and color remote jog handle. Includes enclosure, coolant system and chip augers. Anchor kit required for installation. EC-1600 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Vertical Machining Center; 16" x 12" x 10" (406 x 305 x 254 mm), 40 taper, 15 hp (11.2 kW) vector drive, 10,000 rpm, 1200 ipm (30.5 m/min) rapids, high-speed 10-station automatic tool changer, coolant pump, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, and rigid tapping. Three-phase power only. SMINIMILL Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

5-Axis Vertical Machining Center, 50" x 26" x 25" (1270 x 660 x 635 mm), with removable 8.27" (210 mm) 2-axis trunnion rotary table, 50-taper geared-head, 30 hp (22.4 kW) vector drive, 30+1 side-mount tool changer, 710 ipm (18 m/min) rapids, automatic chip auger, programmable coolant nozzle, power-failure detection module, 1 GB program memory, coordinate rotation & scaling, color remote jog handle, macros, high-speed machining, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 95-gallon (360 liter) flood coolant system. VF-5/50TR Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

5-Axis Profiling Vertical Machining Center; 30" x 20" x 20" (762 x 508 x 508 mm), with integrated B-axis trunnion and A-axis rotary table, 40 taper, 30 hp (22.4 kW) vector drive, 8100 rpm, inline direct-drive, 40+1 side mount tool changer, 1200 ipm (30.5 m/min) rapids, high-speed machining software, spindle orientation, macros, coordinate rotation & scaling, Wireless Intuitive Probing System, second home button, color remote jog handle, power-failure detection module, Ethernet interface, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping, and 75-gallon (284 liter) flood coolant system. UMC-750P Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quote

HAAS AUTOMATION, INC. - WWW.HAASCNC.COM

United States

Drill/Tap Center; 28" x 16" x 15.5" (711 x 406 x 394 mm), BT30 taper, 15 hp (11.2 kW) vector drive, 15,000 rpm, 2400 ipm (61 m/min) rapids, high-speed 20+1 side-mount tool changer, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 45- gallon (170 L) flood-coolant system. Anchor kit highly recommended for installation. DT-2 Dimensions Shipping Dimensions Rotary Table Fit Chart

Request for a quoteResults for

Tool changer - Import exportNumber of results

60 ProductsCompany type

Category

- Machine tools, metal machining - parts and accessories (3)

- Robotics (3)

- Adjustment - machine tools (2)

- Gears (2)

- Milling - steels and metals (2)

- Brakes, servo-brakes and accessories (1)

- Drilling - machine tools (1)

- Electric motors and parts (1)

- Laser - cutting and welding machines (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Measurement - Equipment & Instruments (1)

- Polishing - machine tools (1)