- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- titanium and alloys

Results for

Titanium and alloys - Import export

TITANIUM ENGINEERS LTD

United Kingdom

Titanium Beta-C (Grade 19) Bars and Machined Components Some advantages of Titanium Beta-C: • Excellent corrosion resistance • Can be heat treated to yield strength levels above 1170MPa (170 ksi) • Stronger than titanium alloys 6Al-4V and 6Al-2Sn-4Zr-6Mo • Conforms to NACE MR 0175/ISO 15156 • Excellent fatigue resistance • High strength-to-weight ratio Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

TITANIUM ENGINEERS LTD

United Kingdom

Titanium 6Al-2Sn-4Zr-6Mo (6246) Bar and Machined Components Advantages of Titanium 6246: • Conforms to NACE MR 0175/ISO 15156 • Superior corrosion resistance in oilfield environments • Low density/ very high strength-to-weight ratio • Low modulus of elasticity • Low thermal expansion • Non-magnetic • Good fatigue resistance • Can be heat treated to higher strength levels than Ti 6Al-4V (minimum 1040 MPa / 150 ksi) • Good high temperature mechanical properties Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

TITANIUM ENGINEERS LTD

United Kingdom

Titanium 6Al-4V (Grade 5) in Bars and Machined Components Advantages of Titanium 6Al-4V: • Good corrosion resistance in seawater applications • Low density/ high strength-to-weight ratio • Low modulus of elasticity • Low thermal expansion • Non-magnetic • Good fatigue resistance • Good high temperature mechanical properties Call us today for a quotation on +44(0)1675 464200 or email contactus-UK@titaniumengineers.com

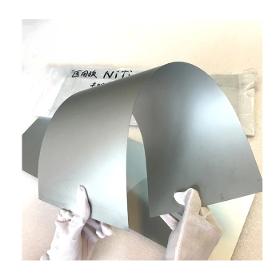

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Specification: 1.Standard:ASTMF2063-12 2.Sheet size: Thickness 0.1-10.0mm Width≤500mm Length≤1000mm 3.Surface: Acid cleaning/ polished 4.AF range:-20-100 Degree ℃ 5.Density:6.45g/cc 6.Feature: superelastic/ shape memory 7.Application:medical 8.Width:≤300mm 9.Length:as required Place of origin: China Payment term: T/T,L/C etc. Lead time: 15-30days Port of shipment:Xiamen,China

Request for a quote

MOH D.O.O

Slovenia

materials Titanium & stainless steel, nickel alloys, aluminium, steel tools surface and heat treatment, sandblasting, NDT testing

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Nitinol (Nickel and titanium alloy) introduction: Nickel titanium alloy is a kind of shape memory alloys, shape memory alloy is able to own plastic deformation at a certain temperature automatically restore to the original shape of special alloy its expansion rate is above 20%, the fatigue life of 1 * ten to the seventh, 10 times higher than ordinary spring damping properties, its corrosion resistance is superior to the current medical * * stainless steel, so it can satisfy the application requirement of all kinds of engineering and medicine, is a very * * of the functional materials in addition to memory alloy has a unique shape memory function, but also has high wear resistance corrosion and other excellent characteristics of damping and super elasticity. Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys. A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties.

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Edelstahlzieherei Mark is traditionally a manufacturer of speciality products, whose uses also include medical equipment. To do justice to the high, specific demands on this product segment and this market, we have given these products a special status within the company. EZM offers EZM Chirusteel and EZM Chirutan products under the brand family name EZM Chiruline. In addition to placing special orders, customers can also fall back on medical grades and versions kept in stock. EZM Edelstahlzieherei Mark offers its customers in the medical equipment sector an extensive range of materials and versions – from stainless materials to titanium, and from ground round bars to sections. Drill wires Implants/Bone plates Implants/Screws Titanium implants >> Current alloy surcharges >> Current scrap surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round Max. bar...

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber offers converters for all common frequencies (20 to 35 kHz) and power requirements (200 to 5,000 W). These converters are especially durable due to the Titanium-Aluminum alloy. Available as planar type together with matching booster or for direct Sonotrode attachment.

Request for a quote

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Niro Präzisionstechnik specializes in the manual mechanical processing of stainless steel thin sheets up to 4 mm. Our specialty are funnels, composite shapes, reductions and transitions, for example from round to square. All connections are welded while avoiding the inclusion of oxygen, and the weld seams are made invisible through careful polishing. The workpieces are machined free of tension and distortion with uniform wall thicknesses. We only process non-rusting materials such as V2A and V4A stainless steel, titanium alloys and aluminum. Our production conditions allow the manufacture of products for clean room applications such as those used in the pharmaceutical industry, medical technology and in the food industry. Suction devices Ring suction Downpipes Nozzles machine parts Assembly

Request for a quote

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Niro Präzisionstechnik specializes in the manual mechanical processing and processing of thin stainless steel sheets up to 4 mm. Our specialty are funnels, composite shapes, reductions and transitions, for example from round to square. We only process non-rusting materials such as V2A and V4A stainless steel, titanium alloys and aluminum. Our production conditions allow the manufacture of products for clean room applications such as those used in the pharmaceutical industry, medical technology and in the food industry. Funnels and reducers from Ø 70 - 900 mm invisibly ground weld seams carefully smoothed transitions to avoid product buildup suitable for clean room applications uniform wall thicknesses free of tension and distortion

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Cutting Sonotrodes specifically for a customer or an application. These Cutting Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel. Cutting Sonotrodes for the food industry are manufactured to precisely meet the required hygiene standards.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Burrs are splinters, fraying, or edges that occur during machining processes. Tyrolit tools make removing these easy. Our nonwoven products are ideal for finer deburring work on materials like stainless steel, nonferrous metals, titanium, and high-alloy steels. Applications include surgical instruments, turbine construction, products for the chemical and food industries, design objects, and more. For coarser deburring and rough grinding, flap or fiber discs are typically used. Tyrolit's product range for deburring and finishing surfaces is extensive. It includes various non-woven products like discs, rolls, belts, and points for use on steel, stainless steel, nonferrous metals, and plastic. Our high-quality polishing program, featuring first-class discs for angle grinders and different polishing pastes, is perfect for removing final scratches. Tyrolit offers tools for every finishing application.

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Welding Sonotrodes specifically for a customer or an application. These Welding Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel.

Request for a quote

UNEX HEATEXCHANGER ENGINEERING GMBH

Austria

High performance plate type heat-exchangers consist of a number of formed, sealable heat-exchange plates according to the respective requirements. The alternating pressed plates and channel spacing cause highly turbulent flow behaviour, optimal self cleaning effect and highest possible heat transfer. Use of high-grade materials such as titanium, titanium palladium, highly alloyed steels and even a UniCarb carbon/graphite version help ensure UniGasket heat-exchangers are extremely economical compared to other heat-exchanger types. The plates are clamped to a rack between frame plate and pressure plate by means of clamping bolts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

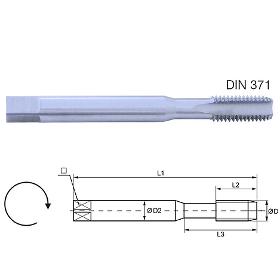

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for through and blind holes, with straight flutes Application: For titanium Material of product: HSSE Surface treatment: no For materials: Pure Titanium and Titanium alloy Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H The geometrie and base material (HSSK powder metal) is made to cut into titanium and titanium alloy. Tap for machine use in blind and through holes. The short lead-in chamfer makes that tap universal in application. The flutes can hold the most part of the chips. Our taps and dies are produced to the highest quality standards, to ensure precise quality threads. Wide range of hand, machine and rolling taps, dies and tools for cutting professional threads on various materials Correct lubrication is important for successful thread cutting and to decrease the wear of taps and dies. We recommend using our lubricants.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: General use (universal tap) Material of product: HSSE Surface treatment: TiAlN For materials: Steel and steel alloys, Stainless steel, Cast iron, Titanium and alloys, Nickel and alloys, Copper and alloys, Aluminium, Aluminium cast and Wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H UNiTap - Universal High-End Threading Tap. A real revolution in production of internal threads: for nearly all materials for nearly all production cases excellent thread quality high life-time unique patented cutting geometry ideal tap for all workshops and manufacturing with changing applications huge costs savings - only one threading tool for all applications The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C.

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A. S.p.A. has always stood out for its multitechnological capabilities and highperformance manufacturing, efficiently and flexibly carrying out the entire production cycle of each fitting, starting from forging through to the final testing phase and any relevant certifications. STANDARD FITTINGS and UNIONS are high quality products that can be supplied both threaded (according to ASME B1.20.1) and socketweld, as well as SWAGE NIPPLES that are available in all standardised variants threaded, BW, plainend, eccentric. This family of standard products is available in carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and others. The material can be certified NSF 61, NACE, PED, and Norsok.

Request for a quote

M.E.G.A. SPA

Italy

The SPECIAL PRODUCTS section includes all FITTINGS, NOZZLES and SPECIAL FLANGES made to specific customer requirements in the following materials carbon steel, stainless steel, duplex and superduplex stainless steel, nickel alloys, copper alloys, titanium and other metals. HEAVY WALL FITTINGS are manufactured from customer specifications, or from accurate design according to the requirements of international codes, including ASME B31.1, B31.3, B31.4, B31.8, ASME B&PV Code Section I, Section III, Section VIII Division 1 and Division 2, PED, RCCM, EN 13480, EN 10253 or others, and is supported by finite element analysis or calculation reports. In this product category, we have special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HCS MULTI-FLUID is a series of carbide circular saw manufactured by Eisele. The key highlights of the HCS MULTI-FLUID series include a firm base frame that is welded, a bigger scope of cutting, an arbitrary saw blade that is accessible to ensure maximum cutting scope that can reach up to 180 mm . The machine has a sturdy and robust base frame on which the combined sawing unit and material feed unit are mounted. This structure combined with a very robust machine design ensures a smooth sawing process with excellent cutting results and a long service-life of the saw blade. The Multi-Fluid system is excellent for high-alloy stainless steels and tool steels, nickelbasedalloys like Inconel and Hastelloy as well as titanium alloys. Depending on the requirements, the following cooling/lubrication components can be combined in a most effective way: — Coolant nozzles for wet processing — Micro-spraying device for minimum quantity lubrication — Cooling vortex tube for dry cutting

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Ti 6Al/4V (Titanium Grade 5) is the most widely used of all the alpha-beta titanium alloys accounting for more than 50% of total titanium usuage. It is typically used in the annealed condition, at service temperatures through 400°C (750°F). Ti 6Al/4V is welded with matching or with ELI filler wire. Ti 6Al/4V is significantly stronger than commercially pure titanium while having the same stiffness and thermal properties excluding thermal conductivity, which is about 60% lower in Grade 5 Ti than in CP Ti. Amongst its many advantages, it is heat treatable. This grade is an excellent combination of strength, corrosion resistance, weld and fabricability. In consequence, its uses are numerous such as for military aircraft or turbines. It is also used in surgical implants. Generally, it is used in applications up to 400°C to improve ductility and toughness in cold-worked condition. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Titanium for Implantable Medical Devices Ti 6Al/4V ELI sheet has found application in medical implants owing to its excellent biocompatibility, high strength, and MRI compatibility. In the cold rolled and annealed temper the material will not exhibit a continuous alpha network at prior beta grain boundaries or a continuous alpha case layer on the surface. Owing to the alloy’s high strength and low ductility, it is difficult to cold draw into finished shapes. Hot forming has been found to be effective.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Ti 3AI/2.5V (Titanium Grade 9) alloy is a near alpha, alpha-beta alloy, sometimes referred to as “half-6-4.” It offers 20 to 50% higher tensile strength than the commercially pure titanium at room and elevated temperatures. It is much more amenable to cold working than Ti 6AI/4V alloy and can be cold worked 75 to 85% to result in moderately high strength and good ductility. Furthermore, it is weldable as the commercially pure grades and has excellent resistance to torsion and corrosion.Ti 6Al/4V is significantly stronger than commercially pure titanium while having the same stiffness and thermal properties excluding thermal conductivity, which is about 60% lower in Grade 5 Ti than in CP Ti. Amongst its many advantages, it is heat treatable. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Because of its strength, unique density and corrosion resistance, titanium has found applications in many industries. For high quality tubing products, it’s often a better substance to use than competing materials like stainless steels or super alloys. Titanium tubes are light weight and exceptionally corrosion and heat resistantThe density of titanium is about 60 per cent of that of steel- or nickel-based alloys giving significant weight savings in aerospace structures. The tensile strength is better than that of austenitic or ferritic stainless steels. Titanium is exceptionally corrosion resistant and exceeds the resistance of stainless steels in most environments. The metal is non-magnetic too, and has good heat transfer properties, with a melting point higher than steel alloys. Titanium is easily worked. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Titanium exhibits a unique combination of properties including excellent corrosion resistance, high temperature resistance, and outstanding strength to weight ratios. Titanium is produced as commercially pure or alloyed. Commercially pure titanium is typically used in implantable medical applications whereas the titanium alloys are produced with the addition of vanadium or aluminum for applications such as aerospace. Hamilton Precision Metals processes strip and foil products in Titanium CP (Grade 1, Grade 2, Grade 4) and Titanium 3Al-2.5V (Grade 9).

Request for a quote

LEBRONZE ALLOYS

France

Machinining of copper, aluminium, titanium alloys and superalloys.

Request for a quoteResults for

Titanium and alloys - Import exportNumber of results

87 ProductsCountries

Company type

Category

- Pipes and tubes, titanium (6)

- Hand tools, non-power (4)

- Printers - computer (4)

- Stainless steels (3)

- Tools & Hardware (3)

- Dentistry - pharmaceutical basic and auxiliary products (2)

- Exhaust systems, vehicle (2)

- Pipe and tube fittings - ferrous metal (2)

- Sheet metal and strips, tinplate (2)

- Steels, nickel (2)

- Cutting - steels and metals (1)

- Blades for saws and cutting machines (1)

- Copper and copper alloys (1)

- Forming - steels and metals (1)

- Foundries - copper, bronze and brass (1)

- Light fixtures, decorative (1)

- Onshore and offshore services (1)

- Orthopaedics and physiotherapy - apparatus, instruments and equipment (1)

- Pipes and tubes, stainless steel (1)

- Polishing equipment and materials (1)