- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- threaded inserts for plastics

Results for

Threaded inserts for plastics - Import export

SPIROL

Germany

Moulded-In Inserts are placed over core pins by an operator or a pick-and-place robot prior to the closure of the mould cavity during the plastic injection process. Moulded-In Inserts offer exceptional torque and pull-out resistance due to unrestricted plastic flow around the Insert body, and are often the Insert of choice for thermosets and engineered plastics with a high percentage of filler. The minor thread diameter tolerance is controlled to ensure positive positioning and perpendicularity of the Insert on the core pin during the moulding process. Series 63 is symmetrical eliminating orientation and Series 65 is the same body style in a blind ended version. SPIROL's Moulded-In Inserts are made from 2024 aluminium, a light-weight, lead-free grade. SPIROL’s Series 63 and Series 65 Moulded-In Aluminium Inserts are available in thread sizes ranging from M4 (8-32) up to M8 (5/16-18).

Request for a quote

SPIROL

Germany

Heat / Ultrasonic Inserts are designed for post-mould installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Request for a quote

SPIROL

Germany

The course external thread of SPIROL's Self-Tapping Insert forms an internal thread within a molded or pre-drilled hole during the installation process into a plastic assembly. SPIROL Series 10 Self-Tapping Inserts are thread forming Inserts best suited for softer thermoplastics or thermosets. Self-Tapping Inserts provide the best pull-out resistance for a post-mold installed Insert, yet generally cost more than their post-mold counterparts. The external threads are designed with a thin profile to minimize induced stress in the plastic and have a relative coarse pitch to provide the maximum plastic shear surface to resist pull-out.

Request for a quote

SPIROL

Germany

Press-In Inserts are designed to be pressed into a straight hole without melting the plastic prior to installation. Ideal for use in softer plastics, the helical knurls of the Press-In Inserts are used to provide both torque and pull-out resistance and to ensure good plastic flow as the Insert rotates into the hole. Installation torque to achieve sufficient tension between the threads is not a problem in that the helical knurls are designed so that the direction of the installation torque will have the tendency to drive the Insert into the hole — which of course is not possible — as the threaded joint is tightened. A pilot only slightly smaller than the hole and of sufficient length is designed to assure straight insertion into the hole. Press-In Inserts offer rapid installation with no specialized equipment and achieve good overall joint performance. If installation equipment is required, SPIROL also offers a standard comprehensive line of Insert Installation Equipment.

Request for a quote

SPIROL

Germany

Some of SPIROL's standard Pin Installation Models can be equipped with a pusher punch (in place of a pin insertion quill) to press Threaded Inserts into plastic assemblies. The most appropriate Installation Machine depends on the actual insertion force required to press the Insert into the plastic hole and the desired productivity. Generally speaking, the Model PMH Heavy Duty Installation Machine is typically used for low to medium volume installation, and for medium to high volume installation, SPIROL's Model PH/PHX Platen-Style Installation Machines can be used for simultaneous installation of several Press-In Inserts at the same or different elevations. Due to the length to diameter ratio of Press -In Inserts, it is not possible to cost-effectively tube feed this type of Threaded Insert with SPIROL's automatic feeding and Installation machines.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

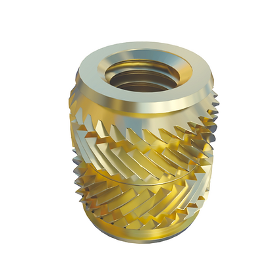

The TECH-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They feature a unique combination of helical knurls with opposite directions and knurled flanges, which substantially increase torque and pull-out resistance, even compared to the SONIC-SERT inserts Installation is simplified by the symmetrical nature of the insert, eliminating the need for orientation during automated or manual feeding Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as TECH-SONIC, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The FLO-SERT are inserts for plastic with installation during plastic molding Suitable for installation in a wide range of thermoplastics and thermosets Blind bottom prevents plastic inflow inside the insert Unique design with three opposite helical knurled bands, combined with hollow parts, provides very high torque and pull out resistance Also known as FLO-TECH, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The HEAT-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics Designed for installation in notch-sensitive amorphous thermoplastic materials. The rounded knurling reduces stress on the contact surface while avoiding stress on the material in which it is inserted Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet They are available in unheaded and headed (flanged) versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. Also a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications Unheaded inserts in addition are symmetrical so they do not need to be oriented during installation process

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

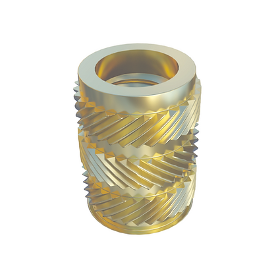

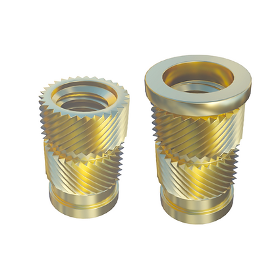

The S29, S30 (Short version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates These inserts were designed to provide faster speed and ease of installation, and at the same time maximize torque and pull out performance. The outer profile was made symmetrical with respect to length, so that the insert does not have to be oriented during the installation process. These inserts are therefore suitable for automatic type installations in large volume The S29, S30 offer much higher torque and pull-out resistance than all other inserts Holes sizes are identical to those of the S19 and S20 inserts to provide an easy alternative

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S29, S30 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S29, S30 inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates These inserts were designed to provide faster speed and ease of installation, and at the same time maximize torque and pull out performance. The outer profile was made symmetrical with respect to length, so that the insert does not have to be oriented during the installation process. These inserts are therefore suitable for automatic type installations in large volume The S29, S30 offer much higher torque and pull-out resistance than all other inserts Holes sizes are identical to those of the S19 and S20 inserts to provide an easy alternative

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The SONIC-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They are designed for quick and economical installation Opposing knurls of the insert offer high torque and pull out performance Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as SONIC-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Short version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S19, S20 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S19, S20 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The S19, S20 inserts are designed with a wide center knurl coupled with two smaller knurls and deep undercuts on both ends to maximize torque and pull out performance They induce very low radial stresses and are therefore particularly recommended in holes with thin walls. In this case the hole must be a bit wider. Optimal size should be determined after appropriate practical tests Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Short version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle In the short version these inserts offer the advantage of having reduced dimensions, shorter installation times and lower costs. On the other hand, the resistance to torque and pull out loads is reduced comparing to long version Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S14 (Long version) are inserts for plastic with heat/ultrasonic installation into tapered holes with an 8° angle These are the longer versions of the S14 Short inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates The tapered form facilitates proper seating and maximizes the surface contact between the insert and hole wall prior to the application of heat or ultrasonic vibration. These inserts are the best choice when using ultrasonic insertion techniques The insert's straight-toothed upper ring and oblique-toothed middle ring provide high torque and pull out resistance, ensuring complete filling of the plastic material in the cavities below Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Inch version from 2-56 to 5/16-18 is available upon request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The PRESS-SERT are press-in expansion inserts to be installed into cylindrical holes Suitable for applications in thermoplastic materials The combination of flat and knurled areas ensure high torque and pull out performance normally achievable only with inserts that are installed by a hot/ultrasonic process These inserts are installed by simple pressure, without need for special equipment Also known as PRESS-LOK, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

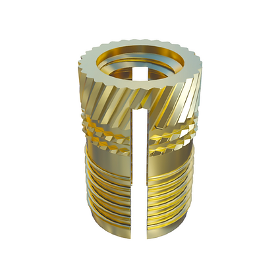

The S50, S51 are press-in inserts to be installed into cylindrical holes Suitable for soft thermoplastics The helical knurl of the outer surface is specially designed to facilitate insertion by allowing maximum plastic sliding of the material in the serration grooves They allow easy and low-cost assembly, as no special machinery is required Offer moderate pull-out and good torque resistance They are available in unheaded S50, and headed (flanged) S51 versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. In the S51 a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications The S50 in addition are symmetrical so they do not need to be oriented during installation process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The THREAD-SERT are self-tapping inserts to be installed into cylindrical holes Suitable for installation in a wide range of thermoplastics and thermosets They are particularly designed for applications that may involve a high tensile load Very easy installation, also using a simple screwdriver Available in two versions with o without head. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. This feature is also useful in applications with electrical contacts Also known as SCREW-SERT, with equivalent shape, features and dimensions

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The S10 are self-tapping thread forming inserts to be installed into cylindrical holes Best suited for ductile, softer thermoplastics or thermosets They provide the best pull-out resistance for a post-mold installed inserts Very easy installation, also using a simple screwdriver Symmetrical shape, they do not need to be oriented during installation process, thus can also be easily used in automatic systems Inch versions from 4-40 to 1/4-20 also are available on request

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The Thread repair kit 4 diameters includes the most popular sizes in the various pitches available (see data sheet). For each of the four diameters the kit contains 1 finishing thread insert tap, 1 installation tool, 1 cutter and 15 thread inserts. All contained in a practical plastic case, easy to store and transport Our thread repair kit is one of the most professional helicoil kits on the market. The installation tool is equipped with a threaded nose to prepare the helicoil thread insert to the size of the thread, making installation simple and safe Excellent choice for repairing damaged, span and worn threads in steel, iron, aluminum, alluminium alloys and hard plastic materials Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

FINN-KORKKI OY

Finland

Our LuxTop -luxury aluminium closures have been developed together with our partners to offer you a luxurious and aesthetic closure to your premium beverage. LuxTop closure consists of a fine aluminium cap and a plastic thread insert. Over many years Finn-Korkki has built a strong set of skills in luxury aluminium closure design, development, and manufacture. These skills have allowed us to offer luxury aluminium closure solutions to different beverage manufacturers. Our key skills are in offering design ideas, experience of stamping aluminium of various thicknesses and knowledge of techniques for securing a plastic thread into an aluminium cap. LuxTop -Luxury aluminium closure gives an excellent look and feel to your premium beverage, and it strengthens the brand message from the packaging side. The closure can be branded by combining different colours for the plastic thread insert and the aluminium cap. The top of the aluminium cap can be printed or embossed.

Request for a quote

SPIROL

Germany

Flexible, versatile solutions for post-mold Insert installation into thermoplastic and thermoset plastics. SPIROL's Installation Machines are the ideal foundation for stand-alone systems and enhanced assembly systems provided by SPIROL. Our standardized, time-tested, modular designs are robust, reliable and easily adjustable — allowing simple customisation to meet the specific needs of your application. More than 80% of the components in the Insert Installation Machines we design are pre-tested and production-proven standard items. This translates into faster delivery, greater reliability, and lowest cost for Insert Installation Equipment of comparable quality. We specialize in custom application-specific part holding devices. Fixturing – holding your components accurately and firmly during insertion – is a critical element to the performance of your assembly equipment.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Metric helicoidal thread inserts in stainless steel (helicoils) Reinforce the thread in low shear strength materials, such as aluminum, aluminum alloys, etc. Allow to restore a damaged thread to its initial size, ensure extremely reduced intervention time The reduced diameter of the first turn ensures that the thread insert can be placed into a hole like a regular screw For installation you may use taps and tools available in this sections: Thread insert taps, Installation tools for thread inserts Made in the EU. Intense srl is a market leader in the distribution of fastening systems for sheet metal, plastic and metal for 40 years. It is renowned for its thread inserts and selftapping bushes, which have always been recognized by the market as products of excellent quality

Request for a quote

SOOCHOW ADVANCE INDUSTRIES CO., LTD.

China

threaded insert manufactured by CNC turning and milling material: stainless steel male thread: 7/16-20 UNF-2A female thread: 1/4-20 UNC-2B groove milled. width 0.060 +/- 0.015 inch, depth 0.062 +/- 0.015 inch size: diameter 0.525 +/- 0.015 inch, height 0.54 +/- 0.015 inch packing: individually packed in plastic tray, carton Soochow Advance Industries Co., Ltd., (website: www.sai-parts.com) supplies custom OEM mechanical parts, industrial fasteners, screws, bolts, nuts, industrial fittings, electronic hardware by precision CNC machining, CNC turning, CNC milling, CNC engineering.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg has vertical injection molding machines with a weight of 80g-120g, specializing in the production of cable connector joints and metal insert molding. The product features are small size and high vertical concentricity. Compared to horizontal injection molding machines, the vertical insert molding of metal insert products does not bump the surface of metal parts, especially the metal parts whose surface has been rust-proofed. Due to the downward gravity, the vertical injection molding machine is combined. It is easy to scratch the metal surface when the mold is used, and it also hurts the mold. If you have any plastic parts need insert molding metal components, that we are the good choice for you. welcome contact with us for a quote, you will get a satisfied partner.

Request for a quoteResults for

Threaded inserts for plastics - Import exportNumber of results

26 ProductsCountries

Company type