- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoformed plastic

Results for

Thermoformed plastic - Import export

PROCESS COLOR

Romania

We manufacture thermoformed automotive parts trays, made of plastic (PET). The pictures shown are our models, but we can fully customize, according to the customers’ requirement various specifications, different thickness and sizes. We design and manufacture the thermoforming mold inhouse. Our custom thermoformed trays can be used for multiple applications from disposable trays for packing and shipping to reusable trays and inhouse handling processes.

Request for a quote

PRO COUPE INDUSTRIES

France

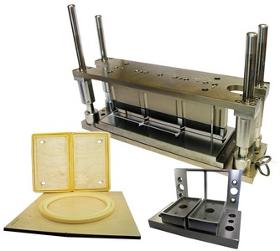

Thermoform tooling for ULMA®, MULTIVAC®, MECAPACK®, CFS® TIROMAT®

Request for a quote

SYNERLINK

France

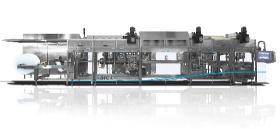

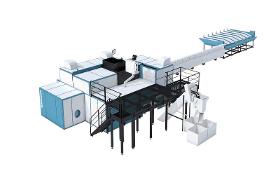

Our AR700 cup thermoforming machine is known for its user friendliness, great reliability, simple design and layout. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Its high adaptability to changing market needs and easy operation and maintenance are ideal for high speed production lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 57,600 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical, straight and open mold cups with or without label.

Request for a quote

SYNERLINK

France

Our DP300 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. This machine versatility and technical efficiency are ideal for medium lines. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed up to 28,800 cups per hour. Our machine can handle various materials (PS, PET, PLA, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SYNERLINK

France

Our DN250 cup thermoforming machine is known for its compact footprint and high cost efficiency. Our gentle multi-layers well-known filling capability is ideal for premium dairy products with high accuracy. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions at a speed of 18,700 to 43,200 cups per hour. Our machine can handle various materials (PS, PET, PP, multilayer) and deliver wide range of conical and straight cups with or without label.

Request for a quote

SYNERLINK

France

Our DN200 thermoforming machine is known for its very compact footprint and small budget. Its simplicity and compactness are ideal for small productions and product tests up to 5,400 cups/hour or 10,800 miniportions/hour. Our equipment is designed to make all operations at ground level. FFS packages are shipped in plastic reels and thermoformed in your plant. Cups are filled and sealed in ultra-clean conditions. The filling volume goes from 10 to 240 ml. Our machine can handle various materials (PS, PP, multilayer). DN200 is optimal for industries where flexibility and affordability are critical.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For sliding properties improvement of machine parts, apparates and precision machinery, e.g. under the influence of oxygen, in vacuum or radioactive radiation Dry lubrication for tools or workpieces in cold- and thermoforming For incorporation in plastics, sealings, packages, sintered metals and improvement of sliding properties For long-term or possibly lifetime-lubrication Advantages and benefits Reduces friction and wear in a wide temperature range High effectiveness due to high affinity of MoS₂ to metals Low friction at highest load capacities Low consumption based on forming of extreme thin sliding films Not electrically conducting and not magnetic Chemically stable except against halogenated gases, concentrated sulfuric- and nitric acidFor best adhesion, clean sliding surfaces. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply on small parts in series production by tumbling, under addition of small amounts powder and tumbling

Request for a quote

KUZEY GLOBAL

Turkey

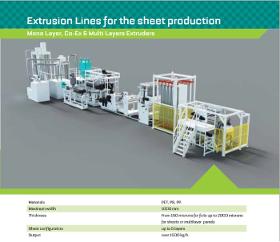

Extrusion lines for thermoforming plastic products

Request for a quote

KUZEY GLOBAL

Turkey

Thermoforming machines for disposable food cups and sheet line extrusion , ofset printing machines

Request for a quote

PROCESS COLOR

Romania

The tray in the picture is model M4318. Tray size exterior down 208x262x27mm exterior up 200x255mm lower compartment 16x185x20mm upper compartment 19x189mm We can make other models of thermoformed plastic trays on request, depending on the customer’s specifications.

Request for a quote

PROCESS COLOR

Romania

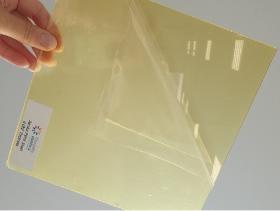

We create and manufacture plastic thermoformed lids, different models and dimensions, according to customer’s specific design and requirments.

Request for a quote

WESTLAKE PLASTICS EUROPE

France

An innovative techno-material combination for aero / defense / rail parts: With a resin manufacturing partner, Arkema, we have succeeded in extruding sheets in an amorphous state (PEKK material already qualified for aerospace) which crystallizes during thermoforming. The fact that the plates are amorphous allows thermoforming deformation and then crystallization offers all the thermal / mechanical / chemical properties of an ultra high performance polymer. Value proposition: advance in the replacement of metal parts / reduce process costs for machined PEEK parts / open the door to the manufacture of large parts (aircraft interior, drones, defense systems, railways, electrical boxes, ducting systems, etc. )

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply various types of EPS-EPP molds/moulds for many applications - industrial packaging, automotive sector, insulation sheets, decorative products, seed trays and many more. You can learn more about our products and services by visiting our web site - https://www.estechtic.net/ or you can send your inquiries to fr@estechtic.net.

Request for a quote

ESTECHTIC EPS-EPP PROCESSING SOLUTIONS

Turkey

We can supply EPS-EPP shape moulding machines, suitable for various applications, product types and mould sizes. While our traditional range of machines is of hydraulic types, we can also supply electrical shape molding machines as well. You can learn more about our products and services by visiting our web site - https://www.estechtic.net/ or you can send your inquiries to fr@estechtic.net.

Request for a quote

ADTECH POLYMER ENGINEERING

United Kingdom

We offer innovative fluoroplastic solutions for your technical applications. We manipulate fluoroplastics into complex profiles using custom manufacturing processes. We flange, flare, coil, bend and cut PTFE, FEP, PFA & PVDF tubing, heat shrink sleeving and sheet to your specific design requirements. We also offer product development and proto-typing in fluoroplastics. Our extensive experience with sealing and manipulating fluoroplastics means we can solve a wide variety of product and application issues. Our fluoroplastic thermoforming and manipulation service range: - Thermoforming of PTFE, FEP & PFA - Welding & Sealing of Fluoroplastics - Tipping & Flanging of PTFE, FEP & PFA - Retractable Coils from FEP, PTFE and PFA Tubing - Custom Pre-formed Tubing Assemblies For more information, visit the adtech.co.uk website or contact us: t: +44 (0)1285 762000 e: sales@adtech.co.uk

Request for a quote

FRIMO GROUP GMBH

Germany

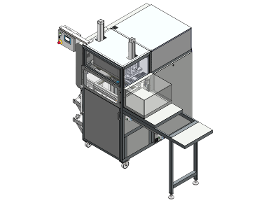

One Concept, Many Applications FRIMO EcoForm machines provide state of the art technology that stems from more than 25 years of thermoforming expertise. These machines have the most modern technology in a compact, user-friendly form. They are designed as standardized single-station machines for vacuum forming and vacuum laminating films and sheet materials. They can also be used in the IMG ( In-Mould Graining) process. EcoForm Thermoforming Machines for Plastic Sheets EcoForm thermoforming machines for plastic sheets are the result of continuous product development and improvement and offer a concept superior in many technical details and convincing in terms of economic efficiency, operating convenience, and process reliability.

Request for a quote

VICTORY LIGHTING (UK) LTD.

United Kingdom

Victory infrared quartz medium wave modules provide a fast, efficient heat source for a variety of industrial processes, primarily those that entail thermoforming of plastics. The range comprises five modules to suit different fitments, and spans wattages from 150–1250W. There is thus a module to suit a wide range of industrial applications, but if you have specific requirements, Victory’s technical team will be happy to discuss your specification and quote for it.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLN ULTRASCHALL AG

Germany

One of the advantages which distinguishes the thermal riveting procedure from other assembly techniques is the safe form-fit. Another advantage: the thermoplastic cannot embrittle as in the case of ultrasonic welding. Apart from the well-established welding techniques for plastic parts in series, KLN Ultraschall AG also develops and produces in Heppenheim equipment for thermal riveting. This technique is still regarded as a very special procedure and has important advantages in comparison with ultrasonic, hot plate, vibration or spin welding. Thus it can be interesting for additional fields of application. This procedure is particularly applied for plastic parts having safety features. In contrast to the ultrasonic riveting, the thermal riveting can be applied without any problems for plate/ plastic assemblies, as no swinging tools are touching the plates which could endanger the assembly.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. During the heating-up phase the hot air riveting does not get into contact with the material. A continous hot air flow heats up the riveting pin. Here the forming of the riveting head is carried out with a cold stamp in a separate station. By the cooling phase next in line a lower relaxation of the plastic material is achieved by pressure and mold constraint

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 625 is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 180 parts per minute. It boasts maximum cutoff quality and userfriendly servo technology in the infeed and transfer unit. Main advantages Short retooling times thanks to innovative servo technology, Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutoff quality, Accurate servo linear infeed without bar stop, for defectfree cutoff surfaces, Accurate servo transfer unit for safe part transport, Versatile kinematics, Optional equipment with heating system

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The COLDmatic CM 45eco is the ideal coldformer for accurate and complex parts from wire, with a production rate of up to 160 parts per minute. It boasts short commissioning times and has a compact design so it takes up less space. Main advantages Easy to operate, Separate lubricant and coolant circuit for maximum tool service life, Very high cutting quality, Accurate parts transport, Versatile kinematics, Optional equipment with heating system, Short commissioning times

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 75 boasts an outstanding concept and is the ideal hotformer for the costefficient production of complex forgings with a diameter of up to 180 mm and an initial weight of up to 7.5 kg. Main advantages Integrated HFE functionality for forwards extruded forgings, Versatile machine kinematics for complex applications, Servohydraulic end stop system for optimal cutoff quality, Lowimpact part discharge reduces the need for remachining, High process reliability thanks to accurate transfer unit with individually monitored grippers

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 35 is the ideal hotformer for the costefficient production of precision forgings with a diameter of up to 75 mm, with a production rate of up to 170 parts per minute. Main advantages Highest productivity in this class, High process reliability, Controlled and lowimpact part discharge, Four forming stations for wide range of applications

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quoteResults for

Thermoformed plastic - Import exportNumber of results

52 ProductsCompany type

Category

- Thermoforming, plastics - machinery (41)

- Food Industry - Machines & Equipment (4)

- Wrapping machines (4)

- Plastic packaging (2)

- Plastic material processing (2)

- 3D printers (1)

- Advertising design - graphic artists and designers (1)

- Aerospace and aeronautics - construction (1)

- Boxes, plastic (1)

- Cutting, plastics - machinery (1)

- ELECTRIC EQUIPMENT (1)

- Hoses, pipes and tubes - plastic (1)

- Plastics moulding (1)

- Silicones (1)