- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- system utilities

Results for

System utilities - Import export

EWS WEIGELE GMBH & CO. KG

Germany

The best of both worlds! Insufficient stability was a fact increasingly associated with the VDI system in recent years. As a result, block tools were preferred more often, although the VDI tools still offer greater diversity and flexibility. So the next step appeared obvious: combining the best of both systems. In cooperation with DMG, we developed the EWS ProLine system in order to fully utilize the potential of new lathes. While EWS ProLine features a conventional VDI shank, it can be optionally mounted to the turret using four screws. For instance, the flexibility of the VDI system can be utilised for lighter machining, and the stability properties of block tools can be utilised for heavy cutting. The angular position of the radial tools is ensured through the Trifix®, the alignment system. Cutting data similar to HSK63 machining centres? The professional audience at the EMO 2011 watched an impressive live demonstration: on a Gildemeister CTX Beta 1250 4A, two surf

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

Optical Sorting Systems are a widely utilized technology used within the food industry; most particularly used in processing harvested foods such as fruits and vegetables, most notably potatoes, and nuts. Optical sorting was designed to help improve product quality, maximize throughput and increase yields. Within an optical sorting system there are four main components, the feed system, the optical system, the image processing software and last the separation system. The optical system utilizes lights and sensors housed above and below the flow of the products being inspected. It works by using a combination of light and sensors to illuminate objects; and to do this Beam-Splitters are one of the optical components used. Within the camera used in the system a Beam-Splitter cube is used to divide the light source coming from a single lens, into different channels; and each channel is filtered to a specific spectral region Read PDF for more data

Request for a quote

ETERIKA LTD

Bulgaria

Vitamin D contributes to the normal functioning of the immune system and the absorption and utilization of calcium and phosphorus, helps the proper functioning of muscles, maintaining healthy bones and teeth, as well as maintaining proper calcium levels in the blood and participating in the cellular process. division.

Request for a quote

ETERIKA LTD

Bulgaria

Wild rose - helps the proper functioning of the immune, respiratory, digestive and urinary systems. Thanks to the content of vitamin C, which is one of the strongest antioxidants, it protects DNA, proteins and lipids from oxidative damage. Collagen, which makes up 30% of the total mass of human protein, is responsible for the constant renewal of the body's cells. Determines the elasticity, firmness and proper hydration of the skin. Vitamin D - contributes to the proper functioning of the immune system and the absorption and utilization of calcium and phosphorus, helps the proper functioning of muscles, maintaining healthy bones and teeth and maintaining proper levels of calcium in the blood, and also participates in the cellular process division.

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Biogas, sewage gas and landfill gas contains not only water vapour but also a whole host of additional impurities such as hydrogen sulphide, NH3 and siloxane, which, when processed in the utilization system can not only lead to a reduction in efficiency, but also result in damage to the system. The dehumidification of the gas before processing is a basic preliminary requirement in order to permit an efficient usage of the biogas and an investment in the sustainability of the utilization system. With the ennox gas chill dryer the gas to be processed is passed through a heat exchanger where the cooled gas can expel any moisture which drips and is collected as condensate. According to the technical requirements of the installation a post-warming or an economical and ecological energy recovery system can be implemented into the system.

ATMOSFER MACHINERY

Turkey

The smart production line for Diesel refers to an advanced manufacturing system that utilizes automation, digital technologies, and data analytics to optimize DEF’s production process, such as AdBlue®. DEF is a solution used in selective catalytic reduction (SCR) systems in diesel engines to reduce harmful nitrogen oxide (NOx) emissions.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

ATMOSPHERIC PRESSURE, MAINTENANCE FREE AND PROTECTED AGAINST EXTERNAL EFFECTS The pressureless gas storage system of Lipp is used for the storage of gas produced on landfill sites, waste water treatment plants and also as external storage on biogas plants. The system is determined by its robust and technical advanced construction where the gas balloon is protected by a galvanized steel tank. This protects the balloon against UV light and also other external factors. The system is mostly utilized at landfill sites or WWTP to buffer the gas before its further processing. The experience gained during the past decades has improved the complete system and the single components and makes it a perfect choice for end users and general contractors.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

INGENERIC GMBH

Germany

INGENERIC OPTICAL SYSTEMS – CUSTOM-FIT! INGENERIC develops and manufactures optical systems and modules, especially designed and optimized for specific customer requirements. A team of experts in the fields of optical, mechanical and electronical design will not only develop the perfect optical design for highest performance. The module will simultaneously be optimized with regard to all other customer specific requirements. Whether this may be a specifically small housing, a maximum permitted weight or specific demands regarding the cooling area – the required specification will be defined in accordance with the demands of the application and then be put into practice. Last but not least, all of our systems benefit from the utilization of INGENERIC’s high quality micro optics, which are well-known all over the world.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Test bench couplings are applied in miscellaneous test benches. By reason of manifold, specific requirements TOK system is designed according to the modular design concept, to be applicable on almost every engine test bench. For specific requirements, e.g. special-test benches, the standard parts can be combined with specific-designed parts to derive solutions corresponding to individual conditions. Advantages of the TOK-ZW coupling system: Lowest possible torsional stiffness utilizing two flexible elements Simple adjustment of the torsional stiffness by changing of elements Compensation of axial-, radial- and angular misalignment Self-centering, backlash-free and maintenance-free Flanges adapted to DIN or SPICER bolt patterns, respectively on demand Variable installation lengths utilizing telescopic spacer shafts Ideal for highest speed Lowest possible weight by using high-tensile aluminium and CFRP We are glad to see that you are interested in our product line and are happy...

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

EAE ELECTRIC

Turkey

Power Distribution Busbar (40A)E-Line DL/SL group Busbar Trunking Systems are utilized in low power circuits that require 40A single phase or three phase electricity in buildings and industrial facilities. 10A / 16A tap off plugs (with and without cartridge fuse) are designed to supply lighting circuits according to their attributes.

Request for a quote

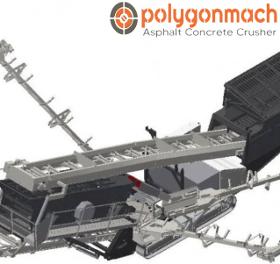

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Technical Specifications of Our Track Cone Crusher Scalper Screen Our track cone crusher scalper screen, model PTK144, is engineered for superior performance and efficiency in various screening applications. This advanced equipment features a hybrid drive system, utilizing motors from Volvo, Cummins, or Perkins, adhering to Tier 3-4 emissions standards. The scalper screen has a top deck size of 4,000 x 1,400 mm and a bottom deck size of 3,380 x 1,300 mm, ensuring efficient material separation. With a weight of 22,500 kg, it combines robust construction with operational flexibility, making it an ideal choice for diverse screening needs. Advanced Hybrid Drive System The PTK144 scalper screen features a state-of-the-art hybrid drive system, combining the power of diesel engines from Volvo, Cummins, or Perkins with the efficiency of electric motors. This innovative drive system ensures robust performance while reducing fuel consumption and emissions.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our track cone crusher scalper screen, model PTK144, is engineered for superior performance and efficiency in various screening applications. This advanced equipment features a hybrid drive system, utilizing motors from Volvo, Cummins, or Perkins, adhering to Tier 3-4 emissions standards. The scalper screen has a top deck size of 4,000 x 1,400 mm and a bottom deck size of 3,380 x 1,300 mm, ensuring efficient material separation. With a weight of 22,500 kg, it combines robust construction with operational flexibility, making it an ideal choice for diverse screening needs.The PTK144 scalper screen features a state-of-the-art hybrid drive system, combining the power of diesel engines from Volvo, Cummins, or Perkins with the efficiency of electric motors. This innovative drive system ensures robust performance while reducing fuel consumption and emissions. The hybrid technology aligns with modern sustainability standards, offering an eco-friendly solution for operators seeking high-perform

Request for a quote

ILK IHRACAT AS.

Turkey

For companies seeking the ultimate in automation and efficiency, fully automated loading and unloading systems are the answer. These systems utilize advanced technology, such as robotics and computerized controls, to handle the entire loading and unloading process without human intervention. Goods are automatically sorted, transported, and loaded onto trucks, eliminating the need for manual labor entirely. Fully automated systems are ideal for high-volume operations where speed, accuracy, and consistency are paramount. In conclusion, automatic loading and unloading systems offer numerous benefits for companies in the transportation industry. Whether it’s conveyor systems, hydraulic lift gates, pallet jacks, or fully automated systems, these technologies enhance productivity, improve safety, and streamline operations. By implementing these systems, companies can reduce labor costs, minimize the risk of injuries, and increase overall efficiency.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In industrial environments a combination feeding hopper and dosing belt conveyor is a frequently utilized system for regulated material feeding and dosage. Before raw materials or bulk materials are fed onto the belt conveyor they are first stored in the feeding hopper. In order to enable accurate material distribution and consistent dosing it guarantees a constant and continuous supply of materials to the dosing belt conveyor. Transporting and dosing materials at a regulated rate however is the job of the dosing belt conveyor. The technology is appropriate for batching mixing or processing operations that call for precise material dosing because it can control the conveyor belts speed and capacity to precisely dispense the required quantity of materials.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Schlötter Systems Dr.-Ing. Max Schlötter GmbH & Co. KG is among the leading manufacturers of electroplating systems and surface treatment facilities. With more than 1,000 systems realized since 1957, we draw upon a wealth of experience in production-ready solutions. At Schlötter, we leverage our expertise in systems engineering and surface technology to precisely tailor each system to the coating processes required by our clients. We design and manufacture rack, barrel, and manual systems, modernize facilities, and support our customers with our systems technology services throughout the long lifespan of our systems. Rack systems Barrel systems Manual systems Electroplating systems Anodizing systems Cleaning and pickling systems Chemical systems Printed circuit board systems Plastic electroplating systems Schlötter Systems in All Surface Technology Industries Schlötter systems are utilized for a wide range of surface technology applications.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Discover high-quality technical plastic injection molded parts for vehicle construction at EWOQE! As an experienced partner to the automotive industry, we offer customized solutions for a wide range of applications, from interior components to technical parts for chassis and powertrain systems. Our dedicated team utilizes state-of-the-art manufacturing technologies and high-quality materials to ensure that our plastic injection molded parts meet the highest quality standards. We understand the demands for durability, resistance, and functionality in vehicle construction and design our products accordingly. Whether you need components for electric vehicles, internal combustion engines, or hybrid vehicles, we are your reliable partner for technical plastic injection molded parts. Rely on our expertise to meet your requirements and achieve your production goals. Contact EWOQE today to learn more about our tailored solutions for vehicle construction and to advance your projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

In industrial environments a combination feeding hopper and dosing belt conveyor is a frequently utilized system for regulated material feeding and dosage. Before raw materials or bulk materials are fed onto the belt conveyor they are first stored in the feeding hopper. In order to enable accurate material distribution and consistent dosing it guarantees a constant and continuous supply of materials to the dosing belt conveyor. Transporting and dosing materials at a regulated rate however is the job of the dosing belt conveyor. The technology is appropriate for batching mixing or processing operations that call for precise material dosing because it can control the conveyor belts speed and capacity to precisely dispense the required quantity of materials. Materials are loaded into the feeding hopper which then transfers the materials to the dosing belt conveyor as part of the feeding hopper and dosing belt conveyor system.

Request for a quote

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Industrial Gas Engine Oil SAE 40 is a specialized low ash gas engine oil engineered for stationary gas industrial engines that endure rigorous operating conditions, both with and without ebullient cooling systems. It finds utility in both 2 and 4-stroke engines. This particular engine oil, Industrial Gas Engine Oil SAE 40, has established its credibility in a variety of scenarios. It has demonstrated its effectiveness in naturally aspirated and turbocharged gas engines running on natural gas, particularly in compression and co-generative applications. This reliability makes it a preferred choice for ensuring the smooth operation and longevity of industrial gas engines under demanding conditions.

Request for a quote

BOSPORAS

Turkey

ADS7 series 7-roller straightener servo feeder models work between 300 and 1600 mm of width and 0,5 and 4 mm of thickness. All of our 7-roller straightener servo machines utilize the piloting system and pinch rollers work synchronized with the straightener rollers. Bosporas produces 7-roller Model with static body and in accordance with CE Regulations. Our straightener servo feeders enable high performance automatic feeding to the presses. Servo feeder and straightener are merged and used in the same group. The practice of our models’ feeding system is easy to set up and to control. The angle between the feeder and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. Feeds the sheet metal in an automated cycle, pre-programmed speed and high delicacy.

Request for a quote

YIBAI LED LIGHTING

China

S5 series LED All in one solar street light Light Source:CREE/Lumileds/Bridgelux/Osram/Samsung/Epistar Controllor:With MPPT function Power range:20W/30W/40W/50W/60W/70W/80W/90W/100W/120W Voltage:DC12V/DC24V Solar light Charge time:6-8hrs Work time:12 hours per night, 4-5 rainy days CCT:3000K/4000K/5000K/6000K Optical :Type II/Type III/Type IV/Type V Efficacy:130lm/W standard, 150lm/W optional CRI:Ra>80 IP Rating:IP66 IK Rating:IK09 Spigot size:25mm-76mm Temperature:-20℃ to +55℃ Warranty:3Years Smart control:Photo sensor, motion sensor, smart city control system Through IoT group management and big data collection, combined with the weather forecast and future lamp usage, as well as the real-time control of lamps by intelligent algorithms, which can significantly improve system utilization efficiency and lighting quality.

Request for a quote

YIBAI LED LIGHTING

China

Light Source:CREE/Lumileds/Bridgelux/Osram/Samsung/Epistar Controller:With MPPT function Power range:20W/30W/40W/50W/60W Voltage:DC12V/DC24V Solar light Charge time:6-8hrs Work time:12 hours per night, 4-5 rainy days CCT:3000K/4000K/5000K/6000K Optical:Type II/Type III/Type IV/Type V Efficacy:130lm/W standard, 150lm/W optional CRI:Ra>80 IP Rating:IP66 IK Rating:IK09 Spigot size:25mm-76mm Temperature:-20℃ to +55℃ Warranty:3Years Smart control:Photosensor, motion sensor, smart city control system Through IoT group management and big data collection, combined with the weather forecast and future lamp usage, as well as the real-time control of lamps by intelligent algorithms, which can significantly improve system utilization efficiency and lighting quality.

Request for a quote

GZ GUANGLI EFE CO., LTD.

China

Good spray paint booth help body shops increase profits, lower operating costs and reduce the environmental impact of the automotive refinish processes. Saved baking Time & Improved Finish Quality Designed to help auto body shop be more productive, efficient and profitable the heating System can be retrofitted to new or existing systems, utilizing supply air for each turbulent air this system reduces the amount of time needed to cure or bake any type of coating. Go Through Type Spray Booth (/spray-booth_c2) 3-folder front & rear door, size: 3×2.8m(W×H) Do not share wall panel in the middle of two spray booth. Each spray booth has 1 piece of emergency door, size: 800×200mm(W×H). There is a small door for going through these two spray booths in the middle. Advantages Can be suitable for any model Fully Completed with AU standard Faster Baking Times No dust clean plenum design Compact system with pre-filters

Request for a quote

LVD

Belgium

Effortlessly handle high tonnage, high production punching requirements with the V-Series. This full-featured 30-ton CNC punch press offers a flexible tool configuration, full sheet utilization and heavy-sheet carrying capacity. A large capacity turret provides the versatility of up to 120 fully indexable tools. The press drive system ensures the best power efficiency for higher tonnage applications. CNC programmable and relocatable work clamps allow full sheet utilization. Modular automation options add even more capacity and flexibility. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy reduction system minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute

Request for a quote

LVD

Belgium

The VX-Series is the choice for production applications demanding high productivity. These full-featured sheet metal punching machines are exceptionally versatile – high hit rates, large feed clearance and powerful control capabilities combine to enable optimal throughput. Full sheet utilization and heavy sheet carrying capacity also add capacity – as do smart features and automation options. It all adds up to punching productivity that is unsurpassed. KEY FEATURES Versatile 48-station thick turret Four programmable 88,9 mm auto index stations Indexable multi-tool capability offers more capacity Three programmable and relocatable work clamps maximize sheet utilization Energy Reduction System minimizes power consumption Quick-change die holders Smart Clamp ensures the smallest possible no-punch zones Smart Stroke automatically optimizes ram stroke Programmable parts removal chute PERFORMANCE-ENHANCING OPTIONS CADMAN-P programming software ABS automatic tool lubrication

Request for a quote

LVD

Belgium

LVD’s tube cutting machines are designed for high production tube fabrication. They provide efficient processing of round, rectangular, square or other standard tube profiles at optimal speeds using a fiber laser. The integration of leading-brand components assures you of top performance and high reliability. Machines are engineered for quick set up of different tube sizes and built for ease of service and maintenance. KEY FEATURES Automatic set-up and run Round, rectangular, square and other profiles are standard Standard components for easy service and maintenance Random standard length 7-position magazine feed 2kW resonator CADMAN-T programming software PERFORMANCE-ENHANCING OPTIONS Bundle feed Seam detection system Outfeed conveyor system Automated nesting for best utilization of materials CADMAN-T embedded advanced programming software

Request for a quoteResults for

System utilities - Import exportNumber of results

43 ProductsCountries

Company type

Category

- Bending machine tools (4)

- Laser - cutting and welding machines (4)

- Concrete preparing - machinery and equipment (2)

- Optical measuring equipment (2)

- Organic cosmetics (2)

- Refrigeration plants and equipment, commercial and industrial (2)

- Tanks, metal (2)

- Automation - systems and equipment (1)

- Car body repair shops - services (1)

- Car tuning equipment (1)

- Chemical industry - machinery and equipment (1)

- Chemicals - Basic Products & Derivatives (1)

- Conveyor belts (1)

- Crushing and grinding machinery (1)

- Cutting - machine tools (1)

- Doors, sliding and folding - house (1)

- Electrical systems and equipment (1)

- Filters, liquid (1)

- Flat screens (1)

- Gas filters (1)