- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- symmetrical inserts

Results for

Symmetrical inserts - Import export

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

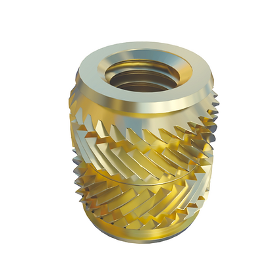

The S29, S30 (Long version) are inserts for plastic with heat/ultrasonic installation into cylindrical holes These are the longer versions of the S29, S30 inserts for higher torque and pull-out resistance Suitable for all types of thermoplastics, even dry and fragile ones such as polycarbonates These inserts were designed to provide faster speed and ease of installation, and at the same time maximize torque and pull out performance. The outer profile was made symmetrical with respect to length, so that the insert does not have to be oriented during the installation process. These inserts are therefore suitable for automatic type installations in large volume The S29, S30 offer much higher torque and pull-out resistance than all other inserts Holes sizes are identical to those of the S19 and S20 inserts to provide an easy alternative

Request for a quote

SPIROL

Germany

Heat / Ultrasonic Inserts are designed for post-mould installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

LT Ultra is your partner for the production of optical surface qualities in injection mold inserts. For example, we can manufacture inserts for the injection molding of spectacle lenses with several focal lengths as well as mold inserts for microlenses or components for vehicle lighting systems. In addition to simple geometries such as spheres or aspheres, we mainly manufacture non-rotationally symmetrical components and freeform surfaces.Mold inserts for a long service life can be made from chemically deposited nickel (NiP). Here you can work directly in the nickel. The advantage is that the very durable nickel can also be deposited on substrates that could not be brought into optical quality themselves or only with great effort. On request, LT Ultra offers the complete delivery of the mold insert as well as the processing of additional parts.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The HEAT-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics Designed for installation in notch-sensitive amorphous thermoplastic materials. The rounded knurling reduces stress on the contact surface while avoiding stress on the material in which it is inserted Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet They are available in unheaded and headed (flanged) versions. Headed (flanged) version provides bearing surface for the mating component to prevent jack-out. Also a screw can be inserted on the opposite side of the flange, allowing to achieve very high pull-out resistance. It also ensures a large contact area, which is useful for electrical contacts and specific applications Unheaded inserts in addition are symmetrical so they do not need to be oriented during installation process

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

The TECH-SERT are inserts for plastic with heat/ultrasonic installation into cylindrical holes Suitable for all types of thermoplastics They feature a unique combination of helical knurls with opposite directions and knurled flanges, which substantially increase torque and pull-out resistance, even compared to the SONIC-SERT inserts Installation is simplified by the symmetrical nature of the insert, eliminating the need for orientation during automated or manual feeding Installation must be carried out using heat conduction or ultrasonic machines. The holes should be sized as indicated in the product datasheet Also known as TECH-SONIC, with equivalent shape, features and dimensions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRISTOL MAID HOSPITAL METALCRAFT

United Kingdom

Standard level single column easy clean procedure trolleys Quick & easy disassembly, assists thorough & deep cleaning Seamlessly welded, one piece 304 grade stainless steel frame Recycled polypropylene one-piece top & side panels, smooth surfaces & radiused edges assists cleaning (compatible with steam cleaning) Top Panel - Raised edges on three sides provide defined grab points to act as push handles, whilst an integral rim at the front contains spillages (max load 30kg) Side Panels - incorporate runners with positive stops, preventing trays from being accidentally withdrawn (symmetrical design allows tray insertion from either side) Carerail fitted to either side to support a wide range of accessories Translucent, impact-resistant trays & dividers, smooth surfaces & radiused edges assists cleaning (compatible with steam cleaning / high temperature machine washing)

Request for a quote

BRISTOL MAID HOSPITAL METALCRAFT

United Kingdom

Standard level, single column easy clean procedure trolleys Quick & easy disassembly, assists thorough & deep cleaning Recycled polypropylene one-piece top & side panels, smooth surfaces & radiused edges assists cleaning (compatible with steam cleaning) Top Panel - Raised edges on three sides provide defined grab points to act as push handles, whilst an integral rim at the front contains spillages (max load 30kg) Side Panels - Incorporate runners with positive stops, preventing trays from being accidentally withdrawn (symmetrical design allows tray insertion from either side) Carerail fitted to either side to support a wide range of accessories Translucent, impact-resistant trays & dividers, smooth surfaces & radiused edges assists cleaning (compatible with steam cleaning / high temperature machine washing)

Request for a quoteResults for

Symmetrical inserts - Import exportNumber of results

8 ProductsCountries

Company type