- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface inspection systems

Results for

Surface inspection systems - Import export

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

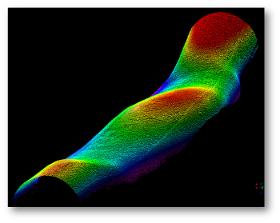

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

As a load distribution panel for the Optigrun system solution "Public Roof with Inspection Chamber". Including Optigrün Water Retention Box WRB 95 with corresponding cut-out.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Polymer Concrete Inspection Chamber PBK to be used as a drainage unit to guide surface water, corresponding to the respective requirements in the suitable composition, on stable substrates (e.g. underground garage decks) with a sufficiently high layer thickness.Inspection chamber for drivable surfaces Different gratings available for vehicular traffic and foot traffic Excess water can also be infed from the drainage level with the aid of TSK water conduits

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Special version of the Optigreen Triangle Maxi Inspection Cham-ber TMK with perforated intermediate floor to guide excess water from higher roof areas.For feeding and conveying excess water from rooftops located higher up to floors located lower down Conveys water through downpipes directly into a tie-in conduit with an open inlet at the top, e.g. in case of: Cascading drainage from smaller top floors, feeds roof drainage water from downpipes on façades into drainage levels of underground car parks or similar Can be connected to up to 6 WLP Plus and 3 TSK With perforated sheet metal intermediate partition Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Inspection chamber for use on greened or gravelled roof areas above drains in edge areas directly before any ascending structural components.Special inspection chamber for use over roof drainage outlets at the edge before ascending components, especially for outlets at the side through the fascia Chamber walls and cover with inlet slots, possible to connect 2 lengths triangle water conduit plus on three sides Chamber cover with inlet slots, compressive strength approx. 150 kg Insensitive to humid acid Reverse releasable 80 mm high

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Triangle Maxi Inspection Chamber TMK suitable for negative pressure drainage. Combinable with Triangle and TSK water discharge systems. Drainage capacity for 2 % roof pitch and profiles connected to all four sides: 24 l/s. Extendable in 50 and 100 mm increments.

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Edge Inspection Chamber RKS 80 for use on greened or gravelled roof areas above drains on edge areas directly before any ascending structural components.Especially suitable for use around edges in front of rising components Above rainage outlets for green or gravelled rooftops Can be connected to 3 strands of WLP Plus Triangle Water Conduit Inspection lid with entry seals Insulation wedge profile released from the back Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Inspection Chamber TAR 250 to keep roof drainage outlets free with four connection options for TAR 80/250 or TAR 120/250.For pressure drainage and keeping drainage outlets free 4 possible connections for the drainage gutter TAR 80/250 or TAR 120/250 (preperforated openings) Chamber walls and lid with entry seals With aluminium chequered plate Walkable

Request for a quote

OPTIGRÜN INTERNATIONAL AG

Germany

Optigrun Combi Inspection Chamber TKS Plus is a control shaft for use as roof outlet inspection; includes base plate and cover. Extendable in 100 mm increments. Combinable with Triangle Water Discharge Profiles.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

This TM1000 Chain inspection machine has been developed to automatically inspect timing chains. It measures the coordinates of chain pins from the top and bottom surfaces. The machine also measures and quantifies the posture of pins relative to the position. A calibration certificate can be generated.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Inspection of Surfaces 2D and 3D Regarding surface quality inspection for metal products such as cylinder head, gear tooth, it consumes a lot of time and human resources for the inspection. Since parts are inspected by bare eyes or slow speed inspection machines. With the inspection machine HE1000, inspection is much faster, more accurate and fully automated. In addition, there is a 3D laser sensor combined with our 2D inspection head to provide the most accurate result. This sensor is the first in the world to apply the Nobel Prize winning physics technology of optical frequency combs. It utilizes coaxial lasers and high precision range finders. There are some cases that our customers reduced over 90% of the inspection time. urthermore, if parts are inspected by humans, there might be different results by each person, because each of them has a different tendency and criterion.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Visual Inspection of Surfaces This SE1000 Visual inspection measuring machine has been developed to automatically inspect the appearance of dirt, scratches, and other imperfections on various kinds of surfaces of your product. This 2D inspection technology can be used in production lines and is suitable for all kinds of industries that want to improve quality, reduce human involvement in inspection and reduce inspection time. Leveraging this fast, precise inspection machine will help you to improve the quality of your product dramatically.

Request for a quote

NEXTSENSE GMBH

Austria

OSIRIS is a stationary, optical measuring system for inline control of dimensional accuracy and surface quality of long products. With state-of-the-art laser light cutting technology and high scanning rates, the OSIRIS systems offer a complete 3D reconstruction of the product. With the OSIRIS Hot version, up to 1,100 degrees hot long products can be analyzed. The measurement results are displayed in real time on the control terminal and thus allow early corrective action to increase throughput and product quality. The surface inspection function automatically detects and classifies deviations in the product surface (peeling, blow-outs, scoring, rolling etc.). In addition, profile cuts of the long product are simultaneously generated to check length dimensions such as width and height, various radii and angles. Different system sizes allow the measurement of large and small long goods.

Request for a quote

LLA INSTRUMENTS GMBH & CO. KG

Germany

Industrial High-Performance hyperspectral camera systems for sorting applications or quality control purposes. LLA's NIR hyperspectral imaging cameras are based on push-broom technology. The working principle is a surface inspection with a maximum penetration depth of 1mm. Within milliseconds, material will be detected and evaluated.

Request for a quote

LLA INSTRUMENTS GMBH & CO. KG

Germany

The RGB camera model uniScanRGB is a line scan camera and was developed for color machine vision applications. This RGB camera can be installed as stand-alone model or as add-on for LLA's HSI models e.g. for waste paper sorting.

Request for a quote

MICRO-EPSILON

Germany

The requirements for the attachments are just as high as for the actual car body. The reflectCONTROL surface inspection system, familiar from car body inspection, has been adapted to the fast and high-resolution surface inspection of largely flat attachments. It recognizes and classifies the defects in an objective and repeatable way. Thanks to the large measuring field, trays can be measured in many cases in just a single capture.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZUMBACH ELECTRONIC AG

Switzerland

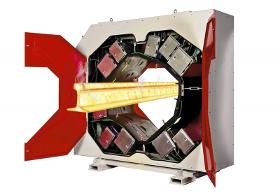

Continuous surface inspection for all kind of products ZUMBACH's all-new SIMAC 40/70 is fulfilling today’s needs for in-line surface inspection of extruded products like pipes, cables and hoses with the consistent implementation of machine vision and machine learning. Defect detection The SIMAC detects anomalies and material defects that are difficult to detect, such as compounds that are not fully crystallised, burnt material inclusions, missing coatings, scratches, ridges, colour defects, bubbles, cracks, holes, etc. Main Features • Continuous in-line surface inspection • The 4 cameras ensure 100% coverage even for small product thanks to overlapping zones. • Advanced algorithms search in the image for defects based on pre-trained examples. • Quick and easy introduction into production lines with the opening on the side • Compact design allows easy maintenance • Works with all surfaces/colors • Data recording for later analysis and defect detector training.

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

BIZERBA SE & CO. KG

Germany

The end-of-line X-ray inspection system offers maximum safety. By using X-ray technology the XRE-D detects contaminated, damaged and defective products and packagings. Besides metallic and non-metallic foreign objects it detects missing, defective or misshaped products as well as overweight or underweight. Thanks to an efficient quick conveyor belt change system the belt can be changed within two minutes. The product inspection system XRE-D X-ray inspection system detects all foreign objects, which due to their density, chemical components or mechanical dimensions absorb X-rays at a higher or lower degree than the surrounding product. During production numerous detection tasks can be safely fulfilled such as the detection of metals, glass, ceramics, stones, raw bones, PVC, Teflon, rubber, glass fibre reinforced plastics etc. In packaged or unpack-aged food (non-magnetic stainless steels and non-ferrous metals in aluminium packaged food). X-Ray inspection is an ideal solution for...

Request for a quoteResults for

Surface inspection systems - Import exportNumber of results

22 ProductsCountries

Company type