- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stone crusher manufacturer

Results for

Stone crusher manufacturer - Import export

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

RT KAUCUK POLIÜRETAN VE MAKINA SAN. TIC. LTD. STI (RT GROUP)

Turkey

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A (VSI) Vertical Shaft Impact Crusher, commonly known as VSI crusher, is a type of crushing machine that utilizes a high-speed rotor with wear-resistant tips or anvils to crush materials into fine particles. Unlike conventional crushers that use compression or impact forces to break down materials, VSI crushers operate by throwing the material against stationary anvils, shaping the material into desired sizes. This process occurs as the rotor spins at high speeds, centrifugal forces propel the material outward, and the impact between the material and the anvils crushes the material into smaller particles. (VSI) Vertical Shaft Impact Crusher are renowned for their ability to produce well-shaped cubical end products and are commonly used in the production of high-quality aggregates, sand, and other construction materials. (VSI) Vertical Shaft Impact Crusher are versatile machines that find widespread applications in various industries, including mining, quarrying, and construction.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The PTV700 is a high-efficiency vertical impact crusher, with advanced technology to better complete the crushing in each operation. This is highly effective in construction projects requiring finely crushed aggregate. The advanced grinder can be applied for a number of purposes in sand production and mineral processing. Considering its technical parameters, this sets a new standard in crushing technology. Material processing is highly accurate, and the quality of an output product is uniformly high due to a closed rotor type featured by this crusher. Thus, the given model is a sufficient and really powerful solution for contemporary requirements in crushing due to its sturdy structure and advanced features.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our track VSI crusher is designed with meticulous care to meet modern crushing applications, especially for the production of sand up to the most important tertiary or quaternary crushing stage. Designed with the vision for versatility and efficiency, this crusher has been placed in the priority list for working with urban projects due to its compact build and performance. The advanced Rockshell 3/5 Port Rotor and Anvil Ring Open Shoe Table are such features that enable this track VSI crusher to deliver better outputs all the time. This makes it the most ideal choice for producing high-quality aggregate to meet the standards required by the current construction industry. Available in three versatile models, namely PTV700, PTV800, and PTV900, this crusher is able to offer solutions to achieve optimal performances at different scales of operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Horizontal Shaft Impactor (HSI) commonly referred to as a Tertiary Impact Crusher is a type of crushing equipment used to further reduce materials that have been processed through primary and secondary crushers into even finer particles. The last stage of crushed materials with exact particle sizes and shapes are usually produced by tertiary impact crushers. They work by applying high-speed impacts to break down the material using a horizontal shaft fitted with hammers or blow bars. A tertiary impact crushers main purpose is to refine the product to the appropriate size and shape in order to meet particular needs in a variety of applications including mining recycling and aggregate production. By producing finely crushed products appropriate for end-use applications tertiary impact crushers play a critical role in the last stage of material processing.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Secondary Impact Crusher is a type of crushing machine that typically comes in the form of a Horizontal Shaft Impactor (HSI). This crusher is designed to provide secondary or tertiary crushing capabilities by generating high-speed impact forces to further reduce the size of the material processed. In comparison to a Primary Impact Crusher, a Secondary Impact Crusher is usually aimed at producing smaller, finer particles and more refined end products. It operates by utilizing a rotating rotor equipped with impact tools such as hammers or blow bars that strike the incoming material, causing it to break apart through impact forces. Secondary Impact Crushers are commonly used after primary crushers in various industries such as mining, quarrying, and recycling to achieve a more refined product size or shape. These crushers excel at producing well-shape aggregates, finely crushed materials, and secondary applications requiring fine particle sizes.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Similar to a primary impact crusher a secondary impact crusher (HSI) is a kind of crushing equipment that produces products with a finer more uniform size. Secondary impact crushers are frequently used following the primary crushing stage because they can handle smaller feed sizes than primary crushers. The material enters the crusher and is struck by hammers or blow bars attached to a rotor which breaks the material apart and reduces its size even more. The capacity of secondary impact crushers to produce high-speed impacts that pulverize material into a finer product appropriate for secondary crushing or final applications in a variety of industries is well known. The capacity of Secondary Impact Crushers to generate a variety of products such as fine aggregates sand and finely crushed materials accounts for their adaptability. In industries like mining and recycling or in the manufacturing of asphalt and concrete aggregates where a higher level of product refinement is necessary

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Primary Impact Crusher is a heavy-duty machine designed to crush large and tough materials into smaller sizes for further processing or use. It operates by utilizing high-speed impact forces generated by a rotating rotor fitted with blow bars or hammers. As the material is fed into the crusher, it is violently struck by the rapidly rotating rotor and impact tools, causing it to break apart into smaller pieces. The primary impact crusher is typically used in applications where large feed sizes and high reduction ratios are required, such as in mining, quarrying, and recycling operations. Its robust construction and powerful impact forces make it suitable for processing various materials, ranging from hard rock to recycled concrete and asphalt. The main purpose of a Primary Impact Crusher is to provide initial size reduction of material, producing a consistent and high-quality product.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

One kind of heavy-duty crushing machinery that uses impact force to reduce material size is the Horizontal Shaft Impactor (HSI) Primary Impact Crusher. The material is shattered by the impact force and the high-speed collisions against the plates or other particles in an HSI crusher which uses a rotating horizontal shaft to propel material towards fixed breaker plates as opposed to jaw crushers which compress the material between two plates. For many aggregate applications a high-quality cubical-shaped product is what this crushing method excels at producing. The HSI crusher is a great option for primary crushing operations where large materials need to be broken down efficiently because of its design which enables it to handle larger feed sizes. Because of its adaptability and capacity to produce a variety of particle sizes with good shape the HSI Primary Impact Crusher finds extensive application in the recycling and construction sectors as well as in mineral processing operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our Track Cone Crusher PTC 200 is intelligently engineered in view to provide the best performance and efficiency in various kinds of crushing applications. It is fitted with the Metso HP200 cone type, with the head diameter of 940 mm and is driven by a 132 kW motor. The overall weight of the crusher is 12,160 kg for adding durability and stability to the operation. The feed opening is 185 mm, while the maximum capacity goes up to 250 Mtph. The PTC 200 is ideal for high-demand crushing, with a track-mounted cone crusher capacity of 250 Mtph (275 Stph). The feed opening is 185 mm or 7 inches, meaning that the feeding dimensions are quite big to keep the flow constant. High capacity ensures meeting project deadlines with much operational efficiency. Strong motor with robust design for continuous performance: you can process big volumes fast and efficiently. The track cone crusher PTC 200 is designed with the Metso HP200 cone model, exclusive in its performance.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

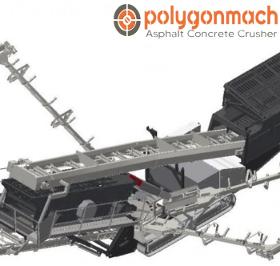

For a variety of uses such as quarry mining and construction mobile crushing and screening plants are advanced machinery systems designed to crush and screen rocks minerals and other materials. These plants combine screening and crushing operations onto a single mobile platform providing great efficiency and flexibility. These plants are a popular option for many industrial operations because they save space and money by doing away with the need for separate crushing and screening units.In order to reduce big chunks of stone and other materials into smaller more manageable sizes for a range of applications mobile crushing and screening plants work by coordinating a series of coordinated actions. First materials like stones are fed into the feeder which controls the flow of materials to the crusher so that the stream is steady and easy to handle.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 40-60 TPH dolomite ore crushing and screening plant is a dolomite processing plant, which processes dolomite ore into the required sizes of any kind of aggregate that is used in construction. A TPH is a unit representing tonnes per hour. In this description, the plant has an input capacity to accommodate and treat between 40 and 60 tons of dolomite ore per hour. Dolomite is an important mineral rock that is high in calcium magnesium carbonate and finds much application in the construction industry, particularly in the manufacture of concrete aggregates and road base materials, among other construction-based products.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The newly installed track-mounted impact crusher meets high-capacity demands of modern construction and mining projects. With this latest crusher, you are assured of a capacity of up to 200 – 350 t/h, hence enabling you to handle even larger volumes of material efficiently. The feeding mouth with an opening size of 1,200 x 900 mm permits easy feeding of larger material. Pre-processing becomes minimal with increased productivity. In turn, this high-capacity performance makes this an asset worthy of our impact crusher for any project that requires robust and efficient crushing solutions. Advanced Crushing with Optimal Opening Size The feeding opening size of our track-mounted impact crusher is 1,200 x 900 mm, the main feature for the effective processing of a wide range of materials. With this feed opening size, blockages are reduced and materials feed effortlessly for smooth operation, enhancing general efficiency in the process of crushing.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our track-mounted impact crusher is a powerhouse, uniquely designed to deliver exceptional crushing performance and boast a high capacity of 200 - 350 t/h. This strong machine has an impressive opening size of 1,200 x 900 mm that enables it to carry out effective processing of big-sized materials. The rotor size is 1100 x 1300 mm. Due to intensive crushing along the whole length of the crusher, an optimal treatment result is achieved. Impressive in weight-54,000 kg-our crusher was meant for harsh conditions to give you years of dependable service on your most demanding projects.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

Our track-mounted impact crusher has been designed to offer superior performance and applicability. The rugged capacity of our machine ranges from 120 to 250 t/h, making it versatile for various applications in the industry. The rotor size stands at 1,050 x 820 mm, giving fair crushing results that will provide good-quality aggregates. This weight of the crusher at 41,800 kg reflects solidity in construction, resilient to bear some of the harshest conditions. These technical specifications speak to our commitment to high-performance equipment that addresses our customer's needs. High Capacity Crushing Optimised The track-mounted impact crusher has a high throughput and is fitted with a capacity ranging from 120 to 250 t/h, thus being perfectly suitable for large-scale projects. This assured high capacity will ensure that you process substantial volumes of material efficiently and hence minimize the hour consumption of operations, raising your productivity.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

100-150 tph Basalt Crushing and Screening Plants are specialized facilities designed for processing basalt stones into various sizes of aggregates at a throughput capacity ranging from 100 to 150 tons per hour. These plants are equipped with machinery and equipment tailored for handling basalt, a durable volcanic stone known for its strength and versatility. The primary function of these plants is to crush large basalt stones into smaller fragments and then screen them to produce high-quality aggregates suitable for applications in construction, infrastructure development, and industrial projects. By efficiently processing basalt, these plants play a vital role in producing robust materials essential for various construction endeavors requiring resilient and reliable aggregates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 250-350 TPH Basalt Crushing and Screening Plants are purposely created for producing a variety of aggregate sizes at throats ranging between 250 and 350 tons per hour. These plants require the availability of specially designed machinery and equipment concerned with the processing of basalt, a resilient volcanic stone with strength and durability. Such plants are mainly aimed at increasing the crushing rate of basaltic stones by reducing them into smaller fragments and screening them effectively so as to produce fine quality and graded aggregate, suited in dimension to mainly these general classes of constructions, infrastructure development, and industrial projects. Properly processed basalt materials ensure a complete solution in the routing of materials, very important in the construction of strong buildings whose degree of strength and toughness is highly reliable.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK CDK Series Primary Impact Crushers have a design that allows the rotor, two pendulum systems and wear plates to work in harmony. Thanks to this compatibility, it offers high performance and low operating costs. It can provide very high size reduction ratios in breaking not very hard and non-abrasive materials. Thanks to these advantages, they are preferred in primary crushing stage in crushing and screening plants. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UGURMAK UMK Series Jaw Crushers are the most preferred types of crushers due to their strong design, ability to crush materials of any hardness, low operating costs and easy maintenance. Depending on the location of the facility, they can be manufactured as mobile, fixed steel legs, fixed concrete legs, and fixed skid chassis.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK brand SMK Series Secondary Impact Crushers can crush medium and high hardness materials such as limestone, dolomite, granite and basalt to the size of asphalt and concrete aggregate. Large size material from the primary crusher can be fed directly. High reduction rate is provided. It is the most preferred secondary crusher type in crushing and screening plants since the initial investment and operating costs are lower than other crusher types. According to the design of the facility, they can be manufactured as mobile, with fixed steel feet, with fixed concrete feet, with fixed skid chassis, pre-screened or pre-fed.

Request for a quote

NOVATEC TEKNOLOJI A.S.

Turkey

The mobile Jaw Crusher with the unique Hydraulic Release Mechanism (HRM) is specially designed for the harsh Environment. We are offering different mobile machinery for crushing stones or slags.

Request for a quote

EVORTLE MACHINERY - MOBILE CRUSHER AND SCREENING, SORTING PLANTS

Turkey

Are you a construction or mining company who deal with recycling, quarry and demolition operations ? Do you have light-weight materials to break into pieces and you do not want your machine to cover too much place? We do not offer you machines, Evortle mission offers you sustainability, efficiency and power. ✅ Jaw crusher (500x350) ✅ 15-100mm adjustable material size ✅ Grid power (electricity) ✅ Easy to transport ✅ Remote control crumble oal, rubble, concrete, tile, brick, briquette, stone, ores, marble, etc.

Request for a quote

EVORTLE MACHINERY - MOBILE CRUSHER AND SCREENING, SORTING PLANTS

Turkey

Crusher inlet : 800X500 ✅Crushing capacity: (up to 110 mm material) 95 tons/hour ✅Euro Tier IV Final Diesel Engine ✅Remote control ✅CT-850 can fit into 40 feet high cube container. ✅ High mobility and power Crumble oal, rubble, concrete, tile, brick, briquette, stone, ores, marble, etc. Video: https://www.youtube.com/watch?v=mE-hCoNrqXo&t=49s&ab_channel=EvortleMachinery

Request for a quoteResults for

Stone crusher manufacturer - Import exportNumber of results

26 ProductsCountries

Company type