- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel needle rollers

Results for

Steel needle rollers - Import export

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

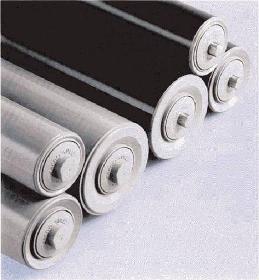

Due to the characteristics of the materials of which they are made, these rollers are used in conveyors operating in highly corrosive environmental conditions.With a state-of-the-art manufacture, they possess the requisites of the specifications for steel rollers on page 4. Operating temperature: 10 ÷ +50 [°C].

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Integratable in the production line, only the inspection windows of the bags will be perforated. The neighbor areas of the inspection windows are left unperforated. The perforation holes are melted down with hot needle rollers of steel at high temperatures.

Request for a quote

GENJECT

Turkey

Together with our Genject brand disposable veterinary syringes, our company cares about the health of our animal friends, helps them to vaccinate in a healthy way and allows them to continue their lives. Disposable veterinary syringes bearing the Genject brand are produced untouched by hand in Genject facilities, which are equipped with the latest technology and have GMP standards. All products bearing the Genject brand are produced in accordance with TS EN ISO 7886-1 standards with all their components. Genject syringes are pyrogen-free, Luer with 6% inclination, and sterile. The body part is made of polypropylene and the piston part is made of polyethylene. Our non-sealed syringes made of stainless steel are suitable for use by veterinarians with 21G 16mm and 18G 38mm special needles.

Request for a quote

GENJECT

Turkey

Genject brand disposable needles are made of stainless steel. It is produced in accordance with TS EN ISO 7864 – TS EN ISO 9626 standards. All of our needles are sterile and non-toxic. Our products have transparent plastic protection.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Needle Roller Cages for General Usage are bearings that provide excellent rotational performance. Their specially shaped cages, with high rigidity and accuracy, precisely guide the needle rollers. Since needle rollers with extremely small dimensional variations in diameter are incorporated and retained in this needle roller cage, they utilize the machining accuracy of the way and are useful in small spaces when combined with shafts and housing bores that are heat treated and accurately ground as raceway surfaces. In addition, since they are lightweight and have high rigidity as well as a large lubricant holding capacity, they can withstand severe operating conditions such as high speed rotation and shock loads, and they are used in a wide range of applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Combined Type Needle Roller Bearings are combinations of a radial bearing and a thrust bearing. Caged Needle Roller Bearings are used as radial bearings and thrust ball bearings or thrust roller bearings are used as thrust bearings. They are compact and very economical, and can be subjected to radial loads and axial loads simultaneously. They are widely used for machine tools, textile machinery, and industrial machinery.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

These bearings consist of a cage made from a steel plate, which is precisely press formed and surfacehardened, and needle rollers with a diameter variation within 2μm. They have a rigid structure and a high lubricantretaining capacity. As they have the lowest sectional height compared with other thrust bearings, they can be used instead of conventional thrust washers and can withstand highspeed rotations with a low coefficient of friction.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Machined Type Needle Roller Bearings are bearings with a low cross sectional height and large load ratings. The outer ring has stable, high rigidity and can be used even for light alloy housings. These bearings are available in metric series and inch series, both of which include a caged type and full complement type. They are suitable for a wide range of conditions including heavy load with either highspeed or lowspeed rotation. In addition, bearings are available with or without an inner ring. The type without an inner ring uses a shaft as the raceway surface, making the design compact.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Needle Roller Cages for Engine Connecting Rods are bearings for use in engine connecting rods. These bearings have superior performance proven in high performance engines of racing motor cycles, and are widely used in small motor vehicles, motor cycles, outboard marines, snow mobiles, highspeed compressors, etc. and also in generalpurpose engines. Bearings for engine connecting rods are used under extremely severe and complex operating conditions such as heavy shock loads, high speeds, high temperatures and stringent lubrication. Needle Roller Cages for Engine Connecting Rods are lightweight, and have high load ratings and high rigidity as well as superior wear resistance to withstand severe conditions.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

In IKO Needle Roller Bearings with Separable Cage, the inner ring, outer ring and IKO needle roller cage are combined, but they can be separated easily. This type has a simple structure with high accuracy. In addition, the radial clearance can be freely selected by choosing an assembly combination. Because they use needle roller cages, these bearings have excellent rotational performance, and are best suited for massproduction, high accuracy products such as machine tools, textile machinery, and printing machines.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Our CLube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The cage is made of synthetic resin, which helps reduce the weight of the device in which the needle roller cage is incorporated. In addition, by optimizing the shape of the cage, the number of needle rollers has increased compared to high carbon steel cages of the same diameter, increasing the load capacity.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Shell Type Needle Roller Bearings are lightweight bearings with large load ratings. They employ a shell type outer ring made from a thin specialsteel plate which is accurately drawn, carburized and quenched, thus providing the lowest sectional height among the Needle Roller Bearings. There are two types of bearings available in this series; the caged type and the full complement type. The appropriate type can be selected according to the operating conditions. The caged type has a structure in which the needle rollers are accurately guided by the cage and thrust rings. It is useful for applications at highspeed rotation. The full complement type needle roller bearing, on the other hand, is suitable for heavyload applications at lowspeed rotation. Since these bearings are pressfitted into the housing, no axial positioning fixtures are required. They are ideal for use in massproduced articles that require economy, and have a wide variety of applications.

Request for a quote

OGGO TECH GEARS, ROLLERS, ENGINEERING

Turkey

This industrial steel roller is manufactured by us, OGGO Tech excels at producing rollersin Turkey, others include steel rollers for packaging, steel, food, beverages, conveyor systems, mining etc rollers. Turkey roller manufacturing and We carry out our roller manufacture without any issues as a professional CNC milling and manufacturing firm. Through our high-quality business, we are the first to choose our rollers sets. The selected applications in tool and roller production are determined by the part, manufacturing time periods, and eventually their dimensions. Roller manufacturing is generally done in soft step procedures, where exact dimensional tolerances are likely to be difficult to achieve. To establish a problem-free hardening lathe, careful preparation for a hardened stage in gear production is essential. Hard operations in gears are easier to undertake at this level.

Request for a quote

GURTEC GMBH

Germany

The composite roller is up to 60% lighter than an equivalent steel roller Available with composite, aluminium and steel shell materials At R&D stage Dimensions: Composite, aluminium and steel shells Roller diameter 152 -178 mm (6” to 7”) Shaft diameter up to 60 mm (2-3/8”) Bearing 6306, 6307, 6308, 6309, 6310

Request for a quoteResults for

Steel needle rollers - Import exportNumber of results

16 ProductsCountries

Company type