- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel foundry

Results for

Steel foundry - Import export

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

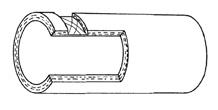

For production in the steel, foundry and glass industries. Temperature resistant from -30 ° C to + 120 ° C. Highly flexible, hot water resistant version. Construction: Abrasion-resistant tube Tension and pressure-resistant fabric inlays Abrasion-resistant, self-extinguishing cover Interior and exterior smooth, fabric patterned optional with heat protection levy of fiberglass (up to + 240 °C) or silicate (up to + 800 °C) Dielectric strength> 6 KV electrically non-conducting R> 109 Ohm Supplied by the roll or cut to length. Also available as spiral hose. Other versions and dimensions on request.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Thanks to many years of experience in steel and metal processing, Tyrolit is a global leader in the steel and foundry industry, particularly in tools for automatic fettling. Modern foundries use high-tech automatic grinding machines, and Tyrolit optimises these processes economically and qualitatively with an attractive range of tools. Tyrolit offers a wide range of tools, including grinding rings, grinding segments, edge-stable resin-bonded grinding wheels and diamond cutting wheels for grey and nodular cast iron. The use of diamond enables a considerable increase in performance. Application engineers provide support in finding efficient solutions, for example when combining diamond and conventional tools. . High economic efficiency . Above-average tool life . Highest surface quality . Reduced noise and dust emissions . Clean cutting quality . Maximum product safety

Request for a quote

VOSSE SP. Z O.O.

Poland

Our last realization - elements of conveyor belt.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

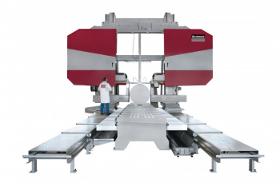

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Developed for slight to heavy grinding and milling for tool and mold making, as well as for deburring, fettling and brushing work in foundries, container and steel construction and mechanical workshops. The lightest and most compact machine in its class for the toughest jobs. * Unbeatable power-to-weight ratio with 2.8 kW at 34 kg. * Ultra-strong asynchronous motor ("continuous runner") with top efficiency. * Indestructible, absolutely maintenance-free, virtually no wear. * Particularly suitable for large tool diameters. * Ideal for working on large surfaces. * Motor overload protection. * Constant speed under load. Comfort and safety features: * Wide range of possible combinations for shafts and handpieces. * Machine can be operated free standing, on table stand or on travelling stand. * Restart protection. * Soft start. * Protection class: IP 55, protection class: I

Request for a quote

MECANUMERIC

France

The rigour and the accuracy for the industrial works, the polyvalence and the simplicity for a maximum of profitability. Designed for the accurate and intensive works, they allow a wide field of applications : metal engraving, fine millings, design, prototyping Refer to the exemples of applications : Moulds and models Health case or box Side windows Aircraft interior furnishing Jewels engraving Masks Household appliances Lights Furniture Aluminium frames The strengths • XYZ stroke 310 x 430 x 120 mm (DMC300) - "Y" reduced to 250 mm in case of automatic tool changer. • XYZ stroke 600 x 610 x 120 mm (DMC600) - "Y" reduced to 420 mm in case of automatic tool changer. • Rigid structure made of steel / Aluminium foundry. • Double guiding by prismatic rails in grinded steel with re-circulating ball bearings. • Ball screw with pre-stressed sockets. • Cinematics fixed table / mobile gantry. • Available in « servo-brushless » motorization. • Economical version with stepper...

Request for a quote

KUTES METAL

Turkey

-Group 1 Moulding Line : Brand : Georg Fischer Type : Impact Standard IM-S-1 otomatik yatay kalıplama hattı Dimensions : 800 x 600 x 250/250mm Capacity: 120 mold / hour Pooring Unit: Inductotherm Visipour P3 Otomatik Tundish Sand Unit : Georg Fischer Conveyor Systems: Georg Fischer Shakeout: Jöst -Group 2 Moulding Line : Brand : HWS (Heinrich Wagner Sinto) Model : Seiatsu EFA-SD otomatik yatay kalıplama hattı Dimensions : 900 x 700 x 300/300mm Capacity: 120 mold / hour Pooring Unit: HWS Otomatik döküm potası Sand Mixer: Eirich RV24 - 3000 Lt - 78 m3 mold sand / hour Sand Control Unit: QualiMaster AT1 Conveyor Systems: VHV Belt Conveyor, Jöst Vibra Conveyor Stakout : Jöst Cooling Tunnel : Jöst

Request for a quote

KUTES METAL

Turkey

4 pieces of 3 tons capacity Dual-Track Inductotherm Induction Furnace 4 pieces of 5 tons capacity Dual-Track Inductotherm Induction Furnace

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

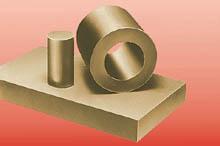

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

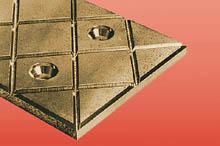

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

OFFICINE CONTERNO SRL

Italy

The major and growing concern for the environment and the reduction of raw material consumption has led to the design of waste recycling plants with a high technological value and low environmental impact. Officine Conterno is able to manufacture complete plants for the recycling and exploitation of aggregates of various kinds such as: BUILDING DEMOLITION RUBBLE BRICK PROCESSING SCRAPS STEEL AND FOUNDRY SLAG UNBURNED ASHES FROM MSW INCINERATORS FLAT AND HOLLOW GLASS SCRAP After undergoing a crushing process, iron removal, screening and separation of non-ferrous metals, all these materials are placed back on the market and are used in building and industry.

Request for a quote

TIKIR MACHINE INDUSTRY

Turkey

For video : https://bit.ly/3rLexUi Automatic Casting Trolleys are especially preferred in iron and steel industry foundries. It is one of the transfer systems that provide high safety and efficiency during the casting of serial molds. It can regulate the line speed and work in accordance with the line speed. They are vehicles that can overturn the crucible (approximately 3500 kg) with a capacity of carrying 1.6 tons of molten steel at 110ᵒ degrees. They are specially designed according to the customer's line specifications. Tıkır Makina has been producing vertical and horizontal transfer systems for the industry since its establishment. It has the ability to produce conveyors, elevators, autonomous driverless forklifts and special design projects according to your needs.

Request for a quote

INSERTEC- INGENIERÍA Y SERVICIOS TÉCNICOS, S.A

Spain

Solutions and engineering services for the design of refractory linings with a focus on equipment performance and efficiency. We work to achieve the highest level of quality with an environmental, health and safety project in both our refractory masses and our prefabricated parts. We offer refractories and precast shapes for a wide range of industrial sectors: Iron foundry Steel foundry Aluminum foundry Cement plants Frites and enamels Heat treatment Steel works Non-ferrous foundry Glass Industry

Request for a quoteResults for

Steel foundry - Import exportNumber of results

22 ProductsCompany type