- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam turbines

Results for

Steam turbines - Import export

APROVIS

Germany

What you can expect from APROVIS gland steam condensers: - Can be used in regenerative and conventional applications - A complete system including blowers - Materials are adapted to the relevant application - Acceptance currently according to PED 2014/68/EU and the ASME Code; additional certifications to follow

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Sunlight can also be channeled and focused to heat water, which can drive steam turbines in large-scale power plants. This Concentrated Solar Power (CSP) was once dominated by glass mirrors due to their unmatched reflectivity. Recent advances in aluminum reflectivity and brightness, partially due to our processing innovations, however, have made the material an effective substitute. Compared to glass, aluminum solar panels offer significantly lighter weight and better ratio performance versus cost.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

SCHARFF TECHNIEK

Netherlands

Clean Steam, clean steam, culinary steam or pure steam, maybe one of these terms sounds familiar to you. Never heard of it, and do you work in the food pharmaceutical or chemical industry? Then it is especially important to read the following information. On this page we briefly explain the difference between different types of steam. That can make all the difference for a safe end product. Steam is an extremely widely used product in many different industries. For example, most of our customers in the food industry use steam in the production process where it comes into direct contact with their food product. For example, soups and sauces are heated by the direct injection of steam. In this case, the quality of steam becomes important. There are different types

Request for a quote

SCHARFF TECHNIEK

Netherlands

The automatically functioning thermal oil boilers are designed for thermal oil with a temperature of up to 400 °C. The thermal oil boiler contains a double rear wall that cools the thermal oil and is part of the VO. This makes a high boiler efficiency of 93% achievable and you will notice this in the gas consumption. Due to the lack of a bricked rear wall, periodic checks of the rear wall are not necessary. As a result, you save on maintenance. Electric thermal oil boilers are also part of our program. All thermal oil boilers can be equipped with all common gas or oil burners both ex works and on site. the burner The installation is supplied as high/low or modulating , depending on the capacity of the Inplan thermal oil boilers .s

Request for a quote

SCHARFF TECHNIEK

Netherlands

The right choice for your application(s). We not only distinguish ourselves by high-quality products, but we are involved. We are on site during all phases of delivery and installation to ensure that everything runs smoothly and according to your wishes. CERTUSS steam generators are of high quality and generate boiler efficiencies of up to 98%. They have been developed from innovative standards, according to PED guidelines, i.e. the latest applicable regulations. And as required, the steam boilers are TUV-approved and provided with a CE certificate, which means that our product complies with the applicable

Request for a quote

SCHARFF TECHNIEK

Netherlands

Your core business. We also take care of the transport, assembly and all accessories, so that you are completely unburdened during the entire rental process. Total package Whether or not you have experience with steam technology, we like to make it as easy as possible for our customers. We take care of the assembly and transport. Our technician installs the electric rental boiler on location and provides expert advice on its use. Do you need additional accessories? Scharff Techniek can provide you with steam fittings such as steam hoses or reducing lines. The electric steam boiler rental, our total package, includes: Rental generating set; Rental water softener; Rental steam fittings; transports; Assembly and disassembly

Request for a quote

SCHARFF TECHNIEK

Netherlands

Electric steam boilers are a good choice for the future. It is a great alternative to a gas-fired steam boiler. We supply various electric steam boilers from the German brand Certuss and the Danish brand AB&Co. Certuss electric steam boilers are compact , economical and easy to operate . They are ready-to-use steam generators with a built-in supply water reservoir and water supply pump. We now also offer an electric steam boiler for greater industrial steam demand. The AB&Co electric steam boilers can handle a capacity of up to 1500 kW. Would you like us to think along with you about making your steam system more sustainable ? Then contact us . Several companies chose an electrical solution before you. Read more about, for example, our collaboration with Nutricontrol .

Request for a quote

SCHARFF TECHNIEK

Netherlands

place at Scharff Techniek. We supply a wide variety of fittings suitable for different qualities of steam, gases and thermal oil. The use of appendages is the way to improve systems that operate by means of pressure. These parts can be connected separately to, for example, a steam or oil boiler, a water supply network and are even used in shipbuilding technology.

Request for a quote

SCHARFF TECHNIEK

Netherlands

There are different steam boilers for different capacities of steam requirements . In addition, gas and oil as fuel for steam generators are not the only options. Electric steam boilers are also possible these days. Contact us for a free 45-minute consultation and find out which steam boiler is the best choice for you. Do you already have a steam boiler but really no knowledge of steam? You will also find the necessary information here. You will read about the operation of steam boilers, safety and maintenance. Do you have specific questions about energy saving or sustainability ? You can read more about this on the page electric steam boilers

Request for a quote

SCHARFF TECHNIEK

Netherlands

Our knowledge and experience in your industry will make your project a success. Scharff Techniek BV is a healthy and traditional family business, founded in 1983. With a focus on steam and thermal oil, we supply installations and, if desired, we can design and install the complete network. Our customers are production companies in the food industry, (pharma) chemistry and manufacturing industry. Universities and colleges, but also training centers set up by branches. Research centers, laboratories and hospitals. We represent the quality brands Certuss, Inplan and Valsteam in the Netherlands. This guarantees stock deliveries of parts and factory service. With storage centrally located from Utrecht, so always close

Request for a quote

SCHARFF TECHNIEK

Netherlands

Do you need steam temporarily? Then renting an electric steam boiler offers a solution. The rentable steam boilers could, for instance, be a solution when temporary production is planned and this requires more steam. By renting our compact electric steam boilers, you temporarily have a higher steam capacity at your disposal. Another instance could be for testing a test set-up; also then the rental boilers can offer a solution. Scharff Techniek ensures that you can continue to focus on 11/8/22, 9:14 AM Electric Steam Boiler Rental | Scharff technique BV https://scharfftechniek.nl/electric-steam-boiler-rental/ 3/5 Privacy - Terms what you do best. Your core business. We also take care of the transport, assembly and all accessories, so that you are completely unburdened during the entire rental process. Total package Whether you have experience with steam technology or not, we like to make things as easy as possible for our customers. We take care of the assembly

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Used in Paper Factory

Request for a quote

SCW MACHINE

Turkey

WHY MY STEAM WASHING AUTO? • You will save 97% of the water you will spend in water washing. (Aqueous washing average: 70-80 Lt. Steam Car Wash 3-5 Lt) • You will save 97% of the water you will spend in water washing. (Aqueous washing average: 70-80 Lt. Steam Car Wash 3-5 Lt) • When you wash by steam, you wash in 1 hour, while cleaning the outer car. You spend 3-4 hours in the water wash. Why spend extra time? • No brushing required! Thus, the car seats do not damage, wear. • Steam cleaning is hygienic. • Steam gives the car a smooth, vibrant and brighter appearance. • Provides cleaning that you will never get in water washing. WHY IS SCW MACHINE? • CE Certificate (compliance with European Standards) • Internal 10 Ml boom boiler • Washing the inside and outside of the same machine with the same machine (no energy loss) • Up to 33 Lt tank capacity • 15 kW machine • One machine is both dry steam. (Dry steam provides special cleaning for electronic components and breasts.)

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BORSIG GMBH

Germany

With around 160 years of manufacturing expertise in reciprocating compressors, BORSIG offers tailor-made horizontal and vertical compressor solutions for process gases with all auxiliary equipment (turnkey solutions). Our reciprocating compressors are driven either by electric motors, gas engines or steam turbines. They have been developed for heavy continuous operation with lubricated or non-lubricated cylinders. They comply with the design standards of API 618 (5th edition), API 11P/ ISO 13631 as well as other international and manufacturing standards. BORSIG reciprocating compressors stand for long life, high wear resistance and low life cycle costs.

Request for a quote

RILLEX S.R.O.

Slovakia

Manufacturing removable, reusable thermal insulating sleeves, fittings and jackets, mattresses from high quality thermal insulating materials, durable technical fabrics, ISO 9001, such as Fire and Oil Proof Steam Insulation Pipe Sleeves, Thermal Insulation Sleeve Pipe Insulation Jackets, Mattresses, Extreme Heat Sleeve (650ºC), Exhaust Insulation Sleeves, for Pipes, Valves, Filters, Side Valves, Flanges, Pumps. Industries: Automobile, Nuclear plants, Energy, Chemical, Petrochemical, Food, Gas, Pharmaceutical, Boiler houses, Heat production suppliers, Steam pipes... Thermal insulation solutions are up to 1850°C, Industrial fire resistant textiles up to 1100°C. Rillex was est. in 2014, Quality ISO 9001, EU materials, multilingual labour Your Energy Saving may be up to 50%*, Overall cost cutting up to 50%* Organic fillings*

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Durability and corrosive resistance are key criteria when it comes to precision thin wall tubing for industrial condensers. The tube mill at Superior Tube more than meets that requirement, and we supply products to a range of leading engineering companies. In the energy sector, our high quality stainless steel and nickel alloy condenser tubes are used for the cooling, heating or re-heating of fluids or gases within steam turbines that generate electricity. Condenser tubing products can be purchased from Superior Tube as seamless, welded or welded drawn tubes in a multitude of sizes ranging from 0.010” OD to 1.500” OD with wall thickness as light as .003” Please note that we have a minimum order value of £10,000.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers. Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Boiler feed water The so called „Boiler feed water“ is stored in a feed water tank and continuously feeded to the boiler of a steam generator. A big quantity of feed water is needed for example in steam power plants. The boiler generates steam, which is used for heating, for chemical processes or for driving a steam turbine respectively a steam engine. The feed water is purified in a way, that all harmfull components for the boiler are removed or neutralized. Leakages and evaporation loss are compensated by additional water which is purified in the same way than boiler feed water. Very often, valuable well and potable water resources are used for the generation of process water. Environmental regulations restrict this usage of well and potable water continuously and increase the costs for this resources steadily. The conditioning of stream water to boiler feed water helps saving potable water and means cost advantages. The process of conditioning is based on ultra filtration with down

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Waste heat boilers produced from alloy, high alloy and stainless steel according to physical properties, content, flow and process conditions of gas are designed and produced to be Water Pipe Waste Heat Boilers and Flame Smoke Pipe Waste Heat Boilers. In the gas engines and in the gas turbine, the high-temperature waste gas resulting from the combustion is evaluated by producing waste heat boilers and steam, which increases the overall system efficiency. Waste heat boilers designed and produced for heat recycling are to be heated according to flow and process; Industrial facilities Power Plants In cogeneration plants It is used in organic rankine conversion systems (ORC). These heat recovery steam generators (HRSGs), which are used to convert steam back into electricity from steam turbine back-burning gas, are also called HRSG (Heat Recovery Steam Generator) in the Combined Cycle Power Plant (CCPP).

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Mineral turbine oil for hydro, steam, turbines as well as centrifugal compressors

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

High performance turbine oil for steam, gas and combined-cycle turbines

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

Flush oil dedicated to flushing and rinsing of steam turbines' EHC systems in conjunction with HYDRANSAFE FR EHC

Request for a quote

HAMON

Belgium

The RCDC ACC is designed with optimized key sections and equipment to guarantee a maximized efficiency. The steam flows from the turbine into a steam duct and several manifolds to reach the fin tube bundles. The RCDC ACC is designed in streets sitting on a steel leg system (under structure) raised to allow proper air intake into the forced draft modules of A-shape steelframes supporting the fin tube bundles. Once condensed the steam is collected by gravity into a condensate tank located underneath or in the close vicinity of the ACC. The efficiency of the steam condensation process is guaranteed using appropriate and reliable vacuum units. RCDC guarantee the complete system and undertake integral studies related to the ducts and manifolds, the steel leg system and the pipe work and other special studies as appropriate.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

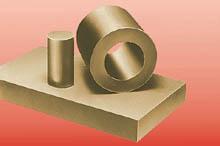

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteResults for

Steam turbines - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Steam turbines (13)

- Lubricants, industrial (3)

- Compressors (2)

- Electricity generators (2)

- Gas turbines (2)

- Aluminium sheets and bands (1)

- Boilers, industrial (1)

- Casting, steel (1)

- Condensers (1)

- Heat recovery systems (1)

- Polishing - machine tools (1)

- Polishing equipment and materials (1)

- Seamless pipes and tubes - ferrous metal (1)

- Silicones (1)

- Technical textiles for industrial applications (1)

- Turbine-driven power stations, installations and equipment (1)

- Turbines (1)