- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel rolls

Results for

Stainless steel rolls - Import export

XUFENG TOOL TECH GROUP LIMITED

China

Material: SS304 Surface treatment: black anodized Tolerence: N6 and H9 Machining method: cnc turining and milling Usage: Industrial machine

Request for a quote

CAIXILHARIAS MANUEL COSTA UNIP LDA

Portugal

» Minimalist sliding system specially suitable for large dimensions (up to 4,000 mm/sash of width or height) » Possible to cover great openings with a glass surface of 94% » Visible section of just 25 mm » Outstanding thermal and acoustic performance » It comes with the possibility of motorised opening for sashes up to 700 kg, and manual opening for up to 400 kg. Additionally, it allows to place multipoint lock systems by operating rod, with or without key » The rollers are placed in the frame, and the sashes count with a stainless steel reinforced rolling area which makes the sliding movement smoother » Possibility of corner sash encounters at 90º without needing a mullion » The motorised version allows to completely hide the sash within the frame in closing position » Maximum glazing thickness 56 mm » Opening possibilities Sliding of 2, 4 or 6 sashes Up to 4 rail configurations 1 sash + 1 fixed / 2 sashes + 1 fixed

Request for a quote

NORELEM FRANCE

France

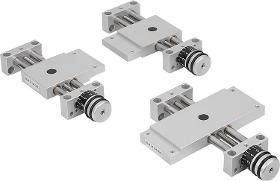

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note The almost playfree guides and absolutely playfree spindle allow for adjustment without the need to loosen or clamp the spindle. The scale graduation is in 5 or 10 increments; 1 increment corresponds to 0.1 mm of travel. The cross stage can be easily combined with positioning stages, vertical stages and other accessories of respective size by the modular principle.

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy, anodised. Guide columns stainless steel, ground. Spindle stainless steel, rolled thread. Guide bearing maintenancefree. Position indicator plastic. Version Radial play on guide < 0.02 mm. No axial backlash. Spindle selflocking, with additional lock. Note Due to the practically playfree guides and absolutely playfree spindle, loosening or clamping of the spindle is not required during adjustments. Digital position indicators with 0.1 mm display accuracy, digits increase with right rotation. The display value of the position indicator can be adjusted by turning the carrier ring. The mounted position of the position indicator can be set in 4 positions with a screw. Within the respective sizes, the positioning stages can be easily combined using the modular principle. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom d) left

Request for a quote

NORELEM FRANCE

France

Steel 1.0401 (C15) or stainless steel 1.4301 (whirled spindles stainless steel 1.4305). Version Steel rolled, bright. Stainless steel up to Tr 40x7 rolled, above this whirled, bright. Note Rolled, high precision trapezoidal thread spindles. ISO trapezoidal thread based on DIN 103. The trapezoidal thread spindle is a transmission thread with relatively high friction. Standard thread forms are selflocking. This has the advantage that they generally do not need to be secured in the rest position. Tolerance class 7e Pitch precision 0.3/300 mm Length sawed with excess, ends not deburred.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

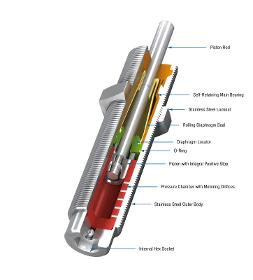

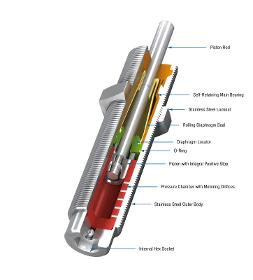

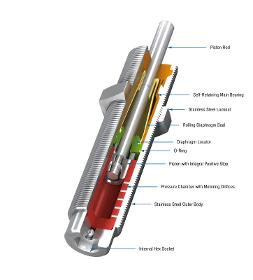

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 136 Nm/cycle Stroke 25.4 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 41 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 20 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

DIETZ GMBH

Germany

In our new production space, we have at our disposal 30 state-of-the-art automated punching & bending machines. In addition to bent wire parts, we also produce bent strip parts here. Production to order with complex forming: Bent strip parts are produced from a broad range of materials, including for instance stainless steel, alloyed or carbon steel, brass, copper, bronze, or even K55 or K75, a specially alloyed steel. We produce complex forms and assembly parts with a strip thickness of 0.15 to 3.00 mm and with a strip width of up to 120 mm; the strip thickness will be dependent on the material. Strip materials: Carbon steels, Stainless steels, Cold-rolled strips, Slit strips. Non-ferrous strips: Brass, Copper,Bronze,Special alloys such as K55 or K75. Strip coatings: Tin-plated, Galvanised, Silver-plated, Gold-plated, Painted, Partial coatings, Special coatings on request.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in custom manufacturing various sheet metal stamping & forming with high quality,can provide relavent processes such as punching,bending,cutting,shearing,riveting,spinning,welding,deep drawing,etc. We have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, we provide one-stop services for metal stamping parts. Materials Available Cold Rolled Steel Stainless Steel Hot Rolled Steel Aluminum Alloys Brass and Bronze Alloys We are professional metal stamping factory from China Ningbo, we have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, If you are interest in our custom metal stamping services, welcome send your design and requirements to us, we shall work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specialize in custom manufacturing various sheet metal hinges with high quality. we are professional sheet metal stamping manufacturer from China Ningbo, we have produced many kinds of metal stamping parts for foreign customers with 15 years experiences, also we have produced many kinds of metal hinges for foreign customers, we provide one-stop services for metal stamping parts. Materials Available Cold Rolled Steel Stainless Steel Hot Rolled Steel Aluminum Alloys Brass If you are interest in our custom metal stamping services, or have any metal hinges need to be customzied,welcome send your design and requirements to us, we shall work a more competitive price for you. China metal stamping manufacturer custom produce Metal Hinge according to customers’ drawing or samples. If you have designed new metal hinge need to be customized from China, please don’t hesitate to contact with us.

Request for a quote

LBI

France

We manufacture rough or fully machined wiper rollers for cold rolling of aluminium and stainless steel Alloy: aluminium bronze with high hardness

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision re-rolled stainless steel strip products can be engineered to specific customer requirements with exceptionally short lead times. Based on our longstanding expertise, we can manufacture stainless steel strip to precise custom sizes, ultra-thin gauges and tightly controlled mechanical properties with any surface finish. We also work closely with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to produce stainless steel foils down to 1.5 microns (.000060”) thickness. Standard Alloys We manufacture stainless steel strip in a variety of chemical and mechanical properties, expertly engineered to your exacting specifications. High performance stainless steel strip material includes: Austenitic: 300 series Martensitic: 400 series Ferritic: 400 series PH Grades 17-7PH®, 17-4PH® Additional options available on request

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316.

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Toilet roll holder with one concealed reserve roll in stainless steel (AISI 304) for surface mounting. Allstainless steel housing; all corners fully welded, visible surfaces satin finished and brushed. Designed for two standard toilet rolls, including one concealed reserve roll, which drops down automatically. Inspection slot to indicate fill level. Accessible for refilling through lockable front flap. Keyed alike cylinder lock in corrosionresistant zinc diecasting. Delivery includes fixing material. Dimensions 148 x 348 x 150 mm

Request for a quote

VOLVAC PACKAGING AND FOOD MACHINERY INDUSTRY LTD. TIC. ŞTI.

Turkey

TECHNICAL DATA. Mashine dimensions:1150x4995x182 h mm Capacity: 360-720 cycle/hour Cycle: 6-8 cycle/minute Container measurements: 187x137x80 h (8 part) Product capacity:1440 packages/hour Pump capacity: 200 m3 Voltage: 45A-400c 50 Hz kW: 7 kW Pneumatic feeding: 16 NI/6-8 bar Outer body: Stainless steel AISI304 Max Roll Width: 720 mm Warranty: 3 years Certificate: CE

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

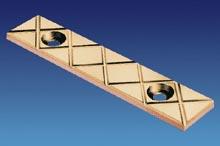

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Stainless, acid-resistant, heat-resistant: no wonder that many clients rely on our THENOX® precision steel strips. The premium flat product made of corrosion-proof stainless steels is produced from hot-rolled steel strip in a cold rolling process. In detail: Through the main alloy element, chrome, a protective layer of chrome oxide is formed on the surface of the austenitic, ferritic and martensitic steels: this gives the material a permanent metallic appearance. Even in chemically aggressive substances. Other carefully alloyed elements, such as nickel, molybdenum and titanium, improve the corrosion resistance and – depending on the alloy – give the different types of steel the required technological properties: for instance good deep-drawing, bending or punching capabilities, or increased elasticity values. We roll steel in thicknesses from 0.05 to 1.50 mm with widths from 3 to 650 mm.

PRAXAS B.V.

Netherlands

The LogTag ST100T-15 external sensor is a strong and safe external sensor specifically designed for use with food. This external sensor is suitable for measuring the core temperature of a product. Place the sensor in the food and measure the temperature accurately.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our four-cylinder rolling machines offer a maximum width of 1900 mm, and pipe twisting up to a diameter of 220mm at max. 6mm gage. In smaller versions 1000mm, for diameter min. 125mm

Request for a quote

NOVELTY STEEL

Turkey

Stainless steel is a very common material to use in fabrication projects, thanks to its versatility and durability, among others. Stainless steel possesses high good corrosion resistance which makes it the primary option for industries such as pharmaceuticals, food, petrochemicals and machinery.The versatility of stainless steel requires different fabricating techniques. Stainless steel is a sensitive material which requires delicate weld preparation practices such as thorough surface preparation prior to commencement of welding. Shoddy surface cleaning may compromise the material features such as corrosion resistance. Stainless steel has definite advantages over other metals and, it’s one of the most expensive metal. This high cost puts additional pressure on fabricators to be more careful in fabrication processes. Stainless steel should be fabricated in a specialized clean workshop to prevent contamination. Also it required specialist steel contractors

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Etched stainless steel 304 plate

Request for a quoteResults for

Stainless steel rolls - Import exportNumber of results

74 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (24)

- Stainless steels (21)

- Cold rolled steel strips (2)

- Joints, pneumatic (2)

- Sheet metals - stamping (2)

- Food industry packaging machinery (1)

- Hinges (1)

- Letter boxes (1)

- Machine tools, metal machining - parts and accessories (1)

- Petrochemical industry - installations and equipment (1)

- Pipes and tubes, stainless steel (1)

- Pipes and tubes, steel (1)

- Rolling mills - ferrous metals (1)

- SMALL METAL PARTS (1)

- Sheet metal and strips, tinplate (1)

- Steel & Metals (1)

- Steel sheets and strips (1)

- Steels, nickel (1)

- Toilet paper (1)

- Windows, aluminium (1)