- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spiral conveyors

Results for

Spiral conveyors - Import export

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application The internal transport of residuals and recyclable fractions, e.g. sievings, screenings and material from grit chambers in waste water treatment plants, as well as various media within production processes, is effected for many years now by belt, spiral and screw conveyors. These systems have proven as very reliable and versatile. As a “connecting element” the PWL GmbH & Co. Anlagentechnik KG supplies the optimal suitable conveyor technology for your specific application. We recommend the encapsulated design of spiral conveyors for process and waste water technology. The spiral conveyors impress with their compact design, the robustness towards clogging and the option to be equipped as a spiral press for simultaneaous dewatering of the conveyed material.

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. Advantages & benefits energy and space-saving vertical conveying that's gentle on the material low-maintenance continuous operation easy-to-clean, hygienic design natural cooling of the bulk solid during the conveying process thanks to long dwell times bulk solids cooled either directly by air or indirectly by water through the use of double bottom or laser-welded Thermplate® bottoms as the spirals

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits energ

Request for a quote

KASAG SWISS AG

Switzerland

Crèmeur with floor mixing device/anchor mixer and scraper, built on the frame with weighing cells. Net volume, operational requirement can be custom-built. Using the KASAG cheese mixer, the holding capacity can be adjusted to your requirements. The cheese mass can be mixed by means of two counter-rotating spiral conveyors.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-vibrating heat exchanger are used in a number of processes in which bulk solids have to be cooled, heated, dried etc. These special-purpose units are able to perform the heat exchange process during transportation. Usually, this occurs indirectly through the use of double bottoms to accommodate the heat exchange medium (oil, water, air, etc.). AViTEQ heat exchangers are employed in practically every industry (chemical, food, plastics, pharmaceutical, recycling and raw materials). The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits gentle product treatment optimised and customised modification to suit existing processes low wear and pra

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

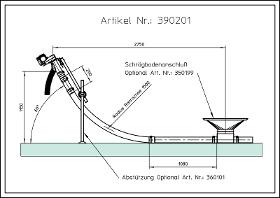

Application The PWL Spiral Sieve HXS presents among the fine screens one of the most efficient solutions for small and medium waste water treatment plants and for some industrial branches. Functional Description In one screening system with one drive only the PWL Spiral Sieve HXS offers three functions. Besides sieving and separation of solids from waste and process water the screenings are conveyed and dewatered at the same time from the screening area for further direct discharge into a container or into a downstream conveyor unit, for example into a PWL Spiral Conveyor. Equipped with either a perforated screening surfaces or wedge wire sieve baskets and installed into tank or channel this Spiral Sieve offers a broad field of applications. The swivelling out mechanism and the transport area which is designed as a conveyor trough with removable covers of the PWL Spiral Sieve provide for easiest maintenance. Your Benefit sieving, transportation, dewatering in one system high...

ACEMAL NV

Belgium

and/or cooling bands We manufacture straight-line, curved or spiral conveyors of all.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

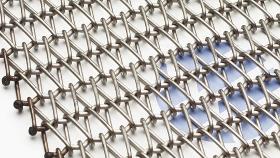

Wire Belt Company’s Balanced Spiral belt is an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications. Benefits of Balanced Spiral belt include straight-running operation, an excellent strength to weight ratio and an extremely wide variety of mesh specifications to suit each individual application.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Flexible Rod belts are designed primarily for multi-tier spiral conveyors commonly used in the food industry. With the ability to side flex, the belt can also be used for conveyors arranged to go around obstacles.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

Wire Belt Company’s Balanced Spiral conveyor belt is an extremely popular mesh design, found in almost every manufacturing industry with a wide ranging number of possible applications. Benefits of Balanced Spiral belt include straight-running operation, an excellent strength to weight ratio and an extremely wide variety of mesh specifications to suit each individual application.

Request for a quote

PKO-SURA COMPANY

Russia

Cooling of confectionery and bakery products before packaging is one of the most long-run (up to 5 hours or more) processes in production. The conveyor belt with the length of more than 300 m is necessary to transport the products during this time. Сура СKБ spiral conveyor is the best option for a conveyor system for cooling products for a long time. Due to the spiral geometry of the belt arrangement in space, it is possible to provide a large length of the belt in a minimum volume that essentially saves production space. In addition, the product is transported on a spiral conveyor belt as softly as possible, without rolling from one lay to another like in multilayered systems.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer spiral conveyor has stood the test of time for transporting differently-sized and -shaped products vertically. The open construction prevents dirt deposits. Common drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears. The mat chain is equipped with rubberised elements so that large gradient angles can be overcome. Technical data: —Conveyor body material: stainless steel —Difference in height when transporting upward: up to 5 m —Difference in height when transporting upward: up to 7 m —Chain widths: 190.5 mm, 304.8 mm, 381.0 mm, 457.2 mm —3 configurations: 0°, 90°, 180° —Conveying speed: up to 50 m/min —Product weight: up to 25 kg —Optionally with lane divider Optional equipment: —Product guides, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —other accessories, such as sensors, stoppers, etc.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Spiral rings are mounted on standard rollers and used to clean conveyor belts. When the idler roller rotates, the spiral rings move the dirt from the center of the belt outwards through a tumbling motion. The spiral rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently fixed on the conveyor roller and are characterized by their abrasion resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

STEINER GMBH & CO. KG

Germany

Impurities of your transported goods are often problematic and can be also guilty of disorders. They may even cause damage. But do not desperate! Our tried and tested magnetic separators will help you. These magnetic separators take care to filter out foreign substances. Simply and reliably.

Request for a quote

STEINER GMBH & CO. KG

Germany

Are you looking to transport pellets inexpensively and save energy? The flexible spiral conveyors from the Bavarian manufacturer Steiner Spiralen (Kirchdorf am Inn) can meet your needs under the most varied conditions. Vertical or horizontal transport of wood pellets can be easily achieved just as well as overcoming large differences in elevation and long transport routes. Steiner Spiralen pellet conveyor systems guarantee you efficient and worry-free transport of pellets. When transporting pellets is the issue, our customers have trusted our conveyor systems for 30 years.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

Spiral conveyance is a well-proven method throughout the world when handling bulk materials in agriculture. In modern fattening establishments a rotating spiral transports the processed food inside the KURO spiral conveyor from the storage tank in to the feeding system. KURO’s wide range of spiral conveyors enables an optimal feeding of your feeding system by using various lengths and radii.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

Spiral conveyance is a well-proven method throughout the world when handling bulk materials in agriculture. In modern fattening establishments a rotating spiral transports the processed food inside the KURO spiral conveyor from the storage tank in to the feeding system. KURO’s wide range of spiral conveyors enables an optimal feeding of your feeding system by using various lengths and radii.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The new FLEXON SafeTopChain was designed with a completely closed upper surface, minimising the risk of crushing in curves or deflections and offering maximum stability for products and workpiece carrier systems. The special surface also enables even the smallest parts to be transported risk-free. Highlights: • Requires the same guides as the normal plastic multiflex chains from the 1700 Series • By using turning disks with a minimum radius of 123.5mm, dynamic friction is replaced by rolling friction; this allows longer conveyors with more curves, as well as vertical/spiral conveyor systems to overcome gradients and providing buffering. • Improved chain geometry enables the use of wider sprockets, thus reducing wear through lower surface pressure when teeth engage.

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

For industries in waste treatment and recycling, we offer conveyor systems that include: Roller conveyors, Sliding conveyors, Speed conveyors, Chain conveyors, Transporting conveyors, Spiral conveyors, Bucket elevators, Bunker conveyors

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

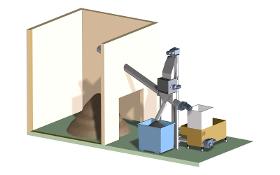

The TransiTec spiral conveyor is suitable for conveying granulate and powdery bulk materials in almost all branches of industry. The flexible spiral conveyor is easy to install and can be easily shortened on site if required and can therefore, due to its flexibility, be adapted to the respective local conditions. Advantages of our flexible spiral conveyor: - Low-noise and dust-free promotion - Low energy consumption - Easy and easy customization on site - Promotion of product mixtures without any segregation - vertical promotion by use of an inner soul - maintenance free - Delivery rate up to 20 m3 / h depending on the product characteristics - Various spiral profiles depending on the application: flat profile, round profile, square profile, normal or reinforced, brush spiral, - Material of the product-contacting metal parts: steel or stainless steel.

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The TransiTec pneumatic conveyor S-WS is used when, for example, local conditions do not allow the use of a spiral conveyor, for example when the minimum radius of a flexible conveyor can not be met or to overcome larger conveyor lines. Here are some features of the pneumatic conveyor: - Suitable for conveying granules and dry powders - Large filter surface - Filter cleaning by means of compressed air - adjustable interval filter cleaning - High throughput - Ideal for long conveyor lines - Fields of application: plastics and food industry as well as chemical and environmental sector. - Different filter sizes up to 10 m2

Request for a quote

TRANSITEC ANLAGENBAU GMBH

Germany

The container emptying station consists of a frame to fix on the ground, a vibrating frame fixed on vibration damper, and one product reception hopper. Depending of the flow properties of the product, this hopper will be designed in conical shape to fix a spiral conveyor (in cas of good flowing product) or in cylindrical shape with an anti-bridging and metering device DZR DM or ZFP DM (for bad flowing products) The vibrating frame ensures the discharge of the product out of the container into the hopper. The anti bridging and metering device DZR beneath the hopper ensures the discharge of the product out of the hopper und doses the product at the same time to the place the product is needed. Depending of the conveying distance, one or more intermediate conveyors have to be set in place. This unit is standardly conceived for rigid containers with a capacity up to 2 m3 or 2 tons. The metering throughput reaches from few liters per hour up to 20 m3/h

Request for a quoteResults for

Spiral conveyors - Import exportNumber of results

28 ProductsCompany type

Category

- Conveyor belts (3)

- Conveyor systems (2)

- Goods handling systems, continuous (2)

- Bakery - machinery and equipment (1)

- Cheese-making machinery (1)

- Folding, bending and welding of rubber and plastic (1)

- Food industry - machinery and equipment (1)

- Grids, gratings and wire mesh (1)

- Industrial containers (1)

- Mechanical transmission systems and components (1)

- Rubber products (1)

- Stairs, spiral (1)