- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special tools for machining

Results for

Special tools for machining - Import export

SYNERLINK

France

EL WRAP is a continuous overwrapper for single cups or packs. This robot can be adapted to suit the desired packs: wrap-around cartons, economy or “drop-through” cartons and can be adapted to any pack size (1x2, 1x4, 2x2, 2x4, 4x4…). The format can be change quickly without the need for special tools. The machine speed can reach 360 packs/minute. EL WRAP is totally designed to be interfaced with any SYNERLINK machines.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

DIETZ GMBH

Germany

We can produce the parts you require using specific tools or on special-purpose machines. We produce complex forms and assembly parts with strip thicknesses of 0.10 to 3.00 and with strip widths of up to 100 mm – depending on the material used. The manufacturing processes that we offer include: Punching, forming, embedding, welding, bolting, riveting and mounting. We perform the assembly of small batches by hand, while larger volumes are performed automated if you so wish. Our hybrid sub-assembly production includes the over-moulding of punched parts made of wire or metal with a variety of plastics or silicones. In order to ensure that the desired braking element features optimum properties, we make use of both the temperature durability and the haptic advantages of silicone and the weight advantage of plastic when combining these materials in this fashion. Guide tube assemblies, a combination of springs and tubes, are part of the hybrid component portfolio.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for thinning of all solvent-based products. Special Thinner cleans and degreases tools, machines and soiled substrates. Also suitable for deresination of surfaces (among others larch, pine).

Request for a quote

GÖCKE GMBH & CO. KOMMANDITGESELLSCHAFT

Germany

Canted profiles in XXL We cant almost every profile with our special tools. Most of the machines used at Göcke are specially constructed; tools for the sheet metal bending presses as well as stencils for sheet metal blanks are self-produced in-house at Göcke. At Göcke Umformtechnik, every desire of the customer and wish for appointments is turned into reality on modern DNC-controlled sheet metal bending presses. For this, we have available an extensive store depot, even special grades. - Cant profiles up to 21 m - Presses up to 3,000 t

Request for a quote

EMSIL TECHTRANS SRL

Romania

Retrofit your machines to enjoy the modern age

Request for a quote

QP PLC

Hungary

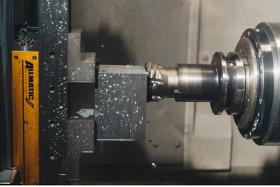

The Automated Serial production qualified for the highest standards in CNC machining in a 6000 sqm. The production lines here are made of automated, robotized cells and are able for high precision mass production of different parts for any industry – engine or structural parts, any other components – as well as aluminium and steel products. Besides the production for our customers there are Data Matrix Code laser engravers, online production control and support system (OEEm) for full traceability, robotized high pressure washing equipment, tightness Quality CMM machines, assembly and logistic services. We have centralised chips and emulsion management, temperature and filtered air control, 7/24 shift pattern.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our lathes machines are: DOOSAN PUMA ¤ 600/¤ 900 x 2500; DOOSAN LYNX300M ¤ 370 x 720; ALPHA 1400X3 ¤ 400 x 1400; DMG MORI NLX 2500/1250 ¤ 400 x 1250 The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our lathes machines are: PRAISE TT60-20L-C1 ¤ 600 x 2000; BLOHM ORBIT 300 x 600; STUDER FAVORIT ¤ 350 x 650; ACRA ASG2880 HSR 750 x 2000. The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our lathes machines are: DOOSAN PUMA ¤ 600/¤ 900 x 2500; DOOSAN LYNX300M ¤ 370 x 720; ALPHA 1400X3 ¤ 400 x 1400; DMG MORI NLX 2500/1250 ¤ 400 x 1250 The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

QP PLC

Hungary

The Customised manufacturing is performed in a 3000 sqm area. We offer a wide range of services: we construct and machine small, medium and large size components. Our milling machines are: DOOSAN DCM3250F 5200 x 3250 x 2700; DOOSAN ACE-DB250 4000 x 2000 x 2000; DOOSAN VM960L 2500 x 960 x 800; DOOSAN MYNX540 1020 x 540 x 530; DOOSAN DNM750 1630 x 760 x 650; HARTFORD HSA-5320VF 5050 x 2100 x 1150, XYZ 1510 1500 x 600 x 600; MORI SEIKI NV5000 800 x 510 x 510; OKK VC-X5005AX 700 x 850 x 610 The strength of this division is the design and manufacturing of fixtures and dedicated machines aiding manufacturing. The secret to our competitiveness is flexibility and high-quality services. Founded in 1993, our company’s philosophy is to serve our clients and partners according to the highest standards, using the most up-to-date technologies.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

High precision steel shaft/splined shaft for connecting/coupling shafts 1) Customer’s drawing or samples accepted. 2) Excellent and high quality control. 3) Prompt delivery. 4) Competitive price. steel shafts 1) Material: Carbon steel , Stainless steel,brass or as per customer’s requirements. 2) Diameter: 0.3-80mm, tolerance:+/-0.005mm. 3) Roundness: 0.003mm. 4) Roughness: Ra0.04. 5) Straightness: 0.005mm. 6) Hardness: HRC/HV. 7) Precision: Grade 6. 8) Length: Max.700mm. 9) Heat treatment:Point hardening,quenching hardening. 10) Surface treatment: zinc plating, nigrescence,chrome plating, nickel plating etc. 11) OEM Service: Providing us the drawing with detail information. 12) Offering products with speciality, quality and efficiency. 13)Package:Plastic bag inside and outer standard carton , pallet.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Machining Parts ● Materials for CNC Precision machining parts We can process product materials are: An aluminum alloy series: all aluminum and aluminum alloy (ASTM Grade from1050-7475), commonly used are: 2011,5052,6061,7075, etc. (2) Copper Alloy Series: all copper and copper alloy, copper, copper, brass, bronze, phosphor (the ASTM grades from C11000 to C38000), commonly used: C11000, C22000, C26000 (3) Stainless Steel Series: all the basic machining stainless steel, the ASTM grades(JIS grade corresponds to the basic, together with the SUS can):201,301,303,304,314,316,420,430,630 Steel series: all the basic machining steel can be processed, for example: 20 # steel, 45 steel, easy to cut iron (common SUM24L, SUM22, Y12, Y15) ● CNC Precision machining parts accuracy Machining accuracy: IT6 level, such as the 10mm dimensions, tolerances can be done 0.009mm, 20mm size tolerances can be 0.013mm ● Maximum size of Precision parts suit to CNC machining

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

CNC Metal Shaft Motor shaft, Fan shaft, Precision shaft, Micro Shaft, Rotor shaft, Pump shaft, Pins, Hinge pin, Metal part, Mechanical precision part. Mechanical precision part/Mechanical precision part. 1) Material: Carbon steel, Stainless steel, brass or as per customer’s requirements. 2) Roundness: 0.001mm 3) Roughness: Ra0.04 4) Straightness: 0.001mm 5) Length: Max. 1000mm 6) Heat treatment: Point hardening, quenching hardening 7) Surface treatment: Zinc plating, nigrescence, chrome plating, nickel plating etc. 8) OEM Service: Providing us the drawing with detail information. 9) Offering products with speciality, quality and efficiency. 10) Package: Plastic bag inside and outer standard carton, pallet. According to client’s demand. Specifications for CNC METAL SHAFT

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INGENIERIA IRADI S.L.

Spain

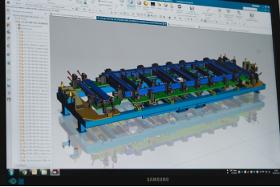

Our team of engineers thoroughly researches each project and designs the most appropriate solution for each customer. The technical office works in accordance with the needs of the customer or independently to meet a stated requirement. We offer complete solutions from design, manufacturing and quality control to on-site commissioning. We have a flexible structure, a dependable supplier network, technical training, and in-depth project knowledge. Our highly qualified technical department works with advanced 3D design programmes and we optimise our designs by means of finite element calculations, eliminating uncertainties and ensuring the correct functioning of each application.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Ingeniería Iradi also designs, develops and manufactures equipment and special machines as well as conducting engineering studies and implementing automation proposals for repetitive manufacturing processes. We design the necessary equipment to facilitate the manufacturing, handling and assembly process We design and manufacture different types of equipment: - for the welding process - for verification and control - for holding - for turning - for detection - for assembly and calibration We have qualified personnel with extensive experience in the assembly and integration of various components and subsystems, and we collaborate closely with entities that specialize in electrical and electronic systems.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Machining according to drawing, from prototypes and unit batches to small and medium-sized production runs We specialize in serial production and machining of all components that require machining on lathes, milling machines, and machining centres.

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Each our component is individually handled in complete care and tested with the latest measuring devices - Mitutoyo. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

EZSO, LLC

Russia

With our equipment you can make flight screws (feathers) up to 50 mm thick of any geometry and from any steel grade. The equipment is fitted with modern CNC control and software, which allows you to maintain accurate repeatability and ideal geometry of the flight screws. SPECIFICATIONS Overall dimensions of the press, L/W/H - 3200 mm / 1350 mm / 1500 mm Overall dimensions of the control unit, L/W/H - 1000 mm / 800 mm / 1650 mm Unit weight ready-assembled - less than or equal to 8000 kg Working pressure in the hydraulic system - 21 MPa Maximum pressure in the hydraulic system - 25 MPa Nominal press power - 100 tons Maximum short-term power - 110 tons Mains voltage - 380 V Power consumption - 22 kW Outer diameter of the coil - not limited Maximum flange height - 680 mm Maximum flange thickness - 2 mm - 50 mm Maximum flange pitch (with standard equipment) - unlimited

Request for a quote

OSMAK RULO MAKINA SAN. VE LTD.STI

Turkey

Defense industry is one of the most important element for every single nation. We are proud to serve Turkish defense industry with costum design machining parts. Osmak is your reliable solution partner of many type of custom design machining parts. Please do not hesitate to contact us to place your order.

Request for a quote

BOGRAMA AG

Switzerland

High-performance drum feeder with low feed height for comfortable working. With a capacity of up to 20,000 cycles/h, the TA 20 is also deployed for the small folds of rotary printing sheets.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer table for inline configuration of BSR 550 Servo with machines interfaced upstream such as cross cutters and digital printing machines.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

BOGRAMA AG

Switzerland

Simple, cost-effective delivery with fixed height.

Request for a quote

BOGRAMA AG

Switzerland

The SAB 550 / 750 stream delivery is used for multiple-up production. Formats from A3 to 30 x 30 mm (minimum) can therefore be delivered in streams Round belt infeed for optimised product delivery Powered top belts with size-independent stream belt Preselection and total counters Motorised height adjustment Available in two working widths, optionally with stream belt extension to 2 meters.

Request for a quoteResults for

Special tools for machining - Import exportNumber of results

39 ProductsCountries

Company type

Category

- Machine tools - metal machining (21)

- Cutting - machine tools (12)

- Machine tools, metal machining - parts and accessories (11)

- Punching machine tools (7)

- Milling - machine tools (6)

- Adjustment - machine tools (1)

- Bellows - machine tools (1)

- Drilling - machine tools (1)

- Folding machine tools (1)

- Food Industry - Machines & Equipment (1)

- Freeze drying - machinery and equipment (1)

- Industrial sheet metal work (1)

- Machine tools - metal shaping (1)

- Machine vision system (1)

- SMALL METAL PARTS (1)

- Steels and metals - machining (1)