- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special seals

Results for

Special seals - Import export

ROLLON GMBH

Germany

International patent registered for the CLEAN ROOM SYSTEM line (DIN EN ISO 14644-1) The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications They are supplied with a certificate issued by the IPA Fraunhofer Institute in Stuttgard, which certifies compliance with class ISO 3 (DIN EN ISO 14644-1), or with class Fed Std 0.01 (FED 209 E). The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head. The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of...

Request for a quote

IGUS® GMBH

Germany

Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) iglidur® PRT slewing ring plain bearing data d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: 1 Aluminum, hard anodized 2 iglidur® J sliding elements

Request for a quote

PRESERVATECH EUROPE SP. Z O.O.

Poland

LPHC are , an acrylic-aluminium made humidification chambers designed to work with our Mini One microclimate generator. LPHC is offered in two standard sizes and also can be built as a special order in different sizes by client request. The body is made of black acrylic with aluminium and front doors from clear acrylic. RH levels are controlled through the Mini One microclimate generator. UNDER CONSTRUCTION CUSTOM STAINLESS STEEL CHAMBERS We are also offering special order microclimate chambers build to client specifications. Those units are constructed from stainless steel and depend on client expectations. All aspects of microclimate can be controlled: relative humidity, temperature and low level of oxygen can be attained. Chambers with controlled relative humidity and temperature can be built with glass doors (as in photo). Units with modified oxygen have solid, special sealed doors. Low level oxygen is generated using nitrogen generator or liquid nitrogen.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Interchange specifications are available. Since the slide unit and track rail dimensions are separate, each can be individually added or exchanged. Slide units include two flange types with different mounting directions and three narrow block types with different heights and mounting directions. Length of Slide Unit Available types include short type, with the same crosssection as the standard type, highrigidity long type and extrahigh rigidity long type. Stainless Steel Stainless steel types, with excellent corrosion resistance, are also available. They are ideal for use in clean rooms for medical equipment, various disc readers and semiconductor manufacturing devices. Ultra Seal Specification The ultra seal specification provides excellent dust prevention performance thanks to a combination of the dedicated track rail finished with an overall ground finish, and the special shape of the end seal and under seal on the slide unit.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

The Mounting Holed Type High Rigidity Crossed Roller Bearing has an integral structure (nonsplit) for both the inner and outer rings, with mounting holes that allows it to be easily attached to equipment. Further it is less subject to peripheral structures such as housing or pressure plate and realizes high rigidity and highaccuracy guidance. Rollers are arranged by intersecting orthogonally between inner ring and outer ring of the single structure. A separator, which can smoothly rotate rollers, is incorporated between rollers. The mounting holes in both inner and outer rings facilitate installation to your equipment. An open type and a sealed type are available. The sealed type incorporates special synthetic rubber sealing.

Request for a quote

KULLEN-KOTI GMBH

Germany

Our special types of sealing brushes consist of 16 particular plastic profiles which we can supply in a comprehensive range of variations. The two constructions of sealing brushes are: Strip brush construction: that means our strip brushes with metal backing are mounted in plastic profiles. Punched brush construction: consisting of a solid plastic profile with bundle holes in which the fill material has been mechanically anchored. Depending on the fill material you can choose a fill density of high EA1, medium EA2 or low EA3. You can choose:- all fill types, e.g. natural bristles and hair, plant fibres, wires and synthetic filaments. - different trim heights (BH) (free bristle length) We can also supply all sealing brush types with fixing holes in the holding flanges, e.g. 22 available sizes of round holes and 13 sizes of elongated holes. Standard lengths are usually 1000 mm or 2000 mm. On request lengths of up to 5000 mm can be supplied, depending on the type of profile. Of...

Request for a quote

KULLEN-KOTI GMBH

Germany

Additional to the versatility of 11 particular types of aluminium profiles they can be supplied anodised resp. plastic coated in all RAL colours. We call as special types our 11 types of sealing brushes which we can produce in a big range of variations on your request. You can choose: - all fill types, e.g. natural fibres and bristles, plant fibres, wires and synthetic bristles- different trim heights (BH) (free bristle length)- the overall length from a few centimeters to the maximum length which can be transported. We also can supply all sealing brush types with fixing holes in the holding flanges, e.g. 22 available sizes of round holes and 13 sizes of elongated holes. Don't hesitate to ask us for other dimensions of fixing holes, too.

Request for a quote

KULLEN-KOTI GMBH

Germany

Our sealing brushes are available in many forms and with a wide variety of profiles. These profiles can also be used as mounting flanges. The special types consist of 11 types of sealing brushes which we can produce in a large range of variations on your request. You can choose: - All fill types, e.g. natural bristles and hair, plant fibres, synthetic filaments and wires.- The quality of the backing material, e.g. galvanized steel, stainless steel (1.4301; 1.4571) or brass.- The trim height (BH) (free bristle length- The overall length from a few centimeters to the maximum length which can be transported. We also can supply all sealing brush types with fixing holes in the holding flanges, e.g. 22 available sizes of round holes and 13 sizes of elongated holes. Don't hesitate to ask us for other dimensions of fixing holes, too.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

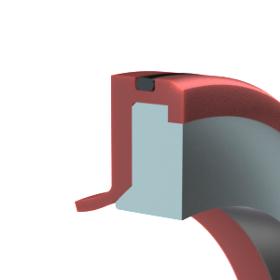

Applications at high speed and low pressure. With O‑ring as secondary seal for sealing in the groove base. Hygienic design without undercuts. No sump formation in front of the seal. Reduced heat buildup due to special lip design. Pressureactivated seal energization. The integrated wedge prevents the sealing lip turning inside out. Very long seal life due to high abrasion resistance. Material only generates low frictional force. Sealing lip does not stick to the mating surface even after prolonged shutdown

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Pelton turbines are used in hydropower plants with a high head. The sealing system specifications are equally high.Control of the turbine output is infinitely variable from part to full load by adjusting the nozzle spear valve. The control unit for linear adjustment of the jet needle can be protected against water and silt infiltration by the MANOY® system seal WP. Types 466 and 486 (both inner sealing) were specially developed for these applications. Types 461 and 481 are for outer sealing configurations. In the context of design, types 481 and 486 must have a split housing. All versions can be supplied with customized profile dimensions for existing groove designs.

Request for a quote

HEBMÜLLER GMBH

Germany

We supply molded seals and special elastomer components made of special compounds based on ACM / AEM, NBR / HNBR and FKM / FPM for various hydraulic applications in mechanical engineering.

Request for a quote

R+L HYDRAULICS GMBH

Germany

Large bore dimensions High torque Topclass seal system Special types High misalignments

Request for a quote

FRANKE GMBH

Germany

The bearing assemblies are equipped with the S10 boot seal as standard. Temperature: –30 ° C to +80 ° C (NBR). Max. Peripheral speed: 5 m / s. For the sealing of the construction (e.g. when using a bearing element) the seal can be ordered by the meter. The joint is then glued with Loctite 401® adhesive. Special seals are available on request. Franke offers Viton seals for high temperatures or aggressive media.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1,870 Nm/cycle Stroke 48.6 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote

NORELEM FRANCE

France

The hygienic stainless steel quarter turn lock prevents bacterial attack and fulfils the strict regulations of testing principles for foodstuff machinery and hygien. The well concieved geometric form, the mirror polished stainless steel surface and the central circumferential seal reliably prevent dirt accumulation. Water, cleaning agents etc. can drain off fully and so prevent contamination. Especially in processes where the resistance of the seal to cleaning and disinfection agents is very important, optimised control cabinets, terminal boxes and command panels are a must. Specifically designed after the principles of Hygienic DESIGN, the hygienic quarter turn lock HD fulfils the strict regulations of the foodstuff processing industry and passes therefore optimally in their professional hygienic applications. The special seal is suitable for high pressure washing up to max. 100 bar and fulfils IP65/67. Furthermore, the seal is temperature stable up to 80°C and the blue

Request for a quote

NORELEM FRANCE

France

The hygienic stainless steel quarter turn lock prevents bacterial attack and fulfils the strict regulations of testing principles for foodstuff machinery and hygien. The well concieved geometric form, the mirror polished stainless steel surface and the central circumferential seal reliably prevent dirt accumulation. Water, cleaning agents etc. can drain off fully and so prevent contamination. Especially in processes where the resistance of the seal to cleaning and disinfection agents is very important, optimised control cabinets, terminal boxes and command panels are a must. Specifically designed after the principles of Hygienic DESIGN, the hygienic quarter turn lock HD fulfils the strict regulations of the foodstuff processing industry and passes therefore optimally in their professional hygienic applications. The special seal is suitable for high pressure washing up to max. 100 bar and fulfils IP65/67. Furthermore, the seal is temperature stable up to 80°C and the blue

Request for a quote

HAGO BAUTECHNIK GMBH

Austria

Load capacity: 15 kN test load EN 124. Material: Frame and cover sections in extruded aluminium. Stainless steel screws. Features: Odour and waterproof access cover in high-quality finish. Only 5 cm installation depth. Particularly suitable for situations where greater installation depths are not possible. The shallow trough results in a weight reduction when filled - so less effort is required to lift the cover. An unrestricted height of 14 mm is available for laying slabs, tiles or parquet flooring etc. Two chemical-resistant special seals. The cover is reinforced with a clamped steel mesh reinforcement. The Lift-Off opening system: Every HAGODECK Type BVA-SL slim Alu comes with a set of lifting keys and precise installation instructions. The HAGO advantage: Jammed covers are lifted by simply turning in the golden lifting key. Recommended applications: For indoor access shafts, for which a pleasant appearance is required. Also, in places where floor finishes may require...

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

The barrel coupling consists of a sleeve provided with semicircular toothing around its internal diameter and a hub that is externally toothed in a similar way. A series of cylindrical barrels, of hardened steel, are inserted in the holes formed by this toothing to act as power transmission elements. Covers with their corresponding special seals serve to assure the perfect tightness of the inner zone, preventing the penetration of dust and guaranteeing the continuity of the necessary lubrication. The most important characteristics and adcantages of barrel roll couplings: for alignment error compensation for ease of assembly especially wear-resistant with high durability minimises effect of alternative bending of the torque on the toothing designed for bearing large radial loads by distributing them over large barrel support surfaces Perfect tightness of the inner zone prevent the penetration of dust We are glad to see that you are interested in our product line and are happy to...

Request for a quote

LUTZ PUMPEN GMBH

Germany

The electric pump set is suitable for low to high viscosity media in the food & pharmaceutical sector and is perfect for dispensing or transferring foodstuffs. * Pump tube equipped with Lutz Original handwheel Features & advantages * optionally with electric or compressed air drive * lubricant-free: therefore no contamination of the pumped medium * facilitated and accelerated emptying processes * universally resistant ETFE shaft bearing * easy disassembly: maintenance without special tools * Sealing modules of the sealless (DL) pump can be replaced

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XM barrel emptying system with volumetric pump based on the endless piston principle. Your advantages: - for medium to high viscosity products (up to 7,000,000 mPas) - suitable for abrasive, shear-sensitive or lumpy materials loaded with fillers - clean wiping of the inside wall of the barrel due to follower plate with special sealing lip - suitable for cylindrical, ribbed or slightly conical barrels, plastic containers or containers with inliners - no lateral squeezing of the medium, as the follower plate is guided almost without pressure - discharge speed electronically adjustable - easy handling - pulsation-free conveyance/discharge - Residual quantity in the barrel: < 1% - compact design Application: Withdrawal of products directly from the delivery or storage container, e.g.: Tomato paste, honey, fats, icing, mascara and much more. pressure-controlled or level-controlled feeding of the products to filling machines or mixing processes.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Pump Set is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for withdrawing or decanting concentrated acids and alkalis. * Media examples: Chloric acid, chromic acid, sulphuric acid, nitric acid, hydrofluoric acid and sodium hypochlorite etc. * Pump tube equipped with Lutz original hand wheel Features & Advantages * No lubricants and therefore no contamination of the pumped medium by lubricants * Optimized Drum emptying * Universally resistant PTFE shaft bearing * Maintenance without special tools * Seal modules of the seal-less (DL) pump are exchangeable

Request for a quote

FÖHRENBACH GMBH

Germany

The RA line descripes a roller beared slide in a special sealed version. The standard type is equipped with a gap seal (approx. 0.5 mm). Special types with felt or nylon scrapers are possible, too. Our slides that run on roller bearings, in single-axis or multi-axis designs, are supplied in the materials grey cast iron and aluminium. The roller bearing slides run in preloaded, hardened and ground Vee-guides. This ensures a smooth, zero-play and extremely precise longitudinal movement - even under high load. Slides which must be designed with T-grooves or higher rigidity can be produced in a reinforced version.

Request for a quote

LUTZ PUMPEN GMBH

Germany

Drum pump is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the withdrawal or decanting of caustic solutions. * Media examples: Sodium hydroxide, potassium hydroxide, ammonia water, formic acid and acetic acid, etc. * Pumping unit equipped with Lutz Original handwheel * suitable for filling or transferring oils such as rapeseed oil and vegetable oil Features & Advantages * optionally with electric or compressed air drive * no lubricants and therefore no contamination of the pumped medium by lubricants * optimized barrel emptying * universally resistant PTFE shaft bearings * Maintenance without special tools * Seal modules of the seal-less (DL) pump can be replaced

Request for a quote

KASAG SWISS AG

Switzerland

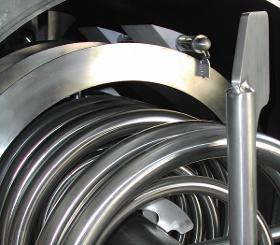

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The pump set is suitable for corrosive, aqueous to slightly viscous media. Perfectly suited for the removal or decanting of alkaline solutions. * Media examples: Sodium hydroxide, potassium hydroxide, ammonia water, formic acid and acetic acid etc. acetic acid etc. * Pump unit equipped with Lutz original handwheel * Suitable for filling or decanting oils such as rapeseed oil and vegetable oil Features & benefits * Optionally with electric or compressed air drive * No lubricants and therefore no contamination of the pumped medium by lubricants lubricants * Optimised drum emptying * Universally resistant PTFE shaft bearing * Maintenance without special tools * Sealing modules of the sealless (DL) pump can be replaced The value of the maximum flow rate is determined on the basis of fixed parameters and always under the same conditions. These can be found on our website.

Request for a quoteResults for

Special seals - Import exportNumber of results

156 ProductsCountries

Company type

Category

- Seals (25)

- Pumps (21)

- Package sealing machinery (9)

- Magnetic equipment (6)

- Creative leisure activities - Articles (4)

- Bearings - ball, needle and roller (3)

- Carwash systems (3)

- Rubber seals (3)

- Sealing rings (2)

- Caps, metal (2)

- Coupling, pneumatic (2)

- Filtering equipment and supplies (2)

- Locks, bolts and keys (2)

- Plumbing, domestic (2)

- Pressure regulators (2)

- Pressure switches (2)

- Quality control and certification (2)

- Art - products and supplies (1)

- Bag filling machinery and equipment (1)

- Bearings, roller (1)