- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sintered products

Results for

Sintered products - Import export

EUROBALT ENGINEERING OÜ

Estonia

Currently, production of the parts from mixed metallic powders is slowly displacing traditional casting and stamping. It is happening because this method is different with its speed and cost efficiency. Wastes from the metal-parts production can be used to produce powders. Parts, produced by this method, have high durability and wear-resistance. Sintering allows to receive parts with precise geometric forms. Parts don’t require further machining. Technology of production of sintering suggests putting metal powders into special forms. They are thermal treated in the gas environment, that allows to increase plasticity of material and also add special polymers. Then, parts are being pressed, rolled and formed. During those processes, parts of the metal powders are strongly melted with each other, creating a monolith mass. In order to provide parts with hardness and wear-resistance, they are being thermal treated in special furnaces. More info https://eurobalt.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Sintered hard ferrite magnets are manufactured by a die pressing followed by sintering process which allows economic production of components in a varied array. Sintered hard ferrite magnets are manufactured by a die pressing followed by sintering process which allows economic production of components in a varied array of sizes and shapes. Ferrite magnets have excellent corrosion resistance and have normal operating capabilities between -40 °C and +250 °C.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin:China Product Name:Tungsten Powder Chemical Composition:99.99%Pure Tungsten Powder Lead time:15days Port of shipment:Xiamen Payment term:T/T,L/C Application 1 For high proportion alloy, green bullets, alloy steel, drill, and products; 2 High-active nano powder can be used as the raw materials of high performance proportion alloy additive quantity (powder from 30% ~ 50%) and preparation of the silk road, and raw materials can be used as additive, high alloy materials, tungsten powder can significantly improve performance and reduce alloy sintering temperature and shorten the production cost saving time and sintering; 3 The nanometer powder can be used as the raw material, nanometer WC preparation of nanocrystalline cemented carbides. Due to the special nanometer powder, and can be used for pore structure ceramic metallization coating W-Mn method of tungsten powder materials.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

In some cases, metal powders can be easily made of separate metal parts. Powders are used to create floor and building structures, as well as for surfacing. Their application is possible in engineering, nanotechnology, metallurgy, aviation and industrial industry. At our site, you can order production of sintered powder parts. In this article, you will learn about the basic methods of obtaining metal powders. Parts made of sintered metal. Methods for obtaining metal powders are divided into two types: mechanical and physico-chemical. Mechanical methods are more common way to produce metal powders. For this purpose, special devices are used. It is especially advantageous to use this method in the manufacture of powders of beryllium, antimony or chromium.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

We provide the powder metallurgy manufacturing with a wide range of advantages for our clients: Excellent surface finishes Excellent tolerance control Cost-effective processing Inexpensive materials A wider variety of alloys to use A high-quality end products Machining minimization while producing parts Controlled porosity for self-lubrication or filtration Materials that can be heat-treated Our production line provides manufacturing Sintered parts for suspension, Sintered parts for oil pumps, Sintered parts for engine, Sintered parts for start motors, Sintered parts for transmission and other custom parts according to your drawings.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVA WERKE AG - NOVA SWISS

Switzerland

Isostatic presses are specifically developed and manufactured by Nova Swiss Sarl in accordance to customer requirements. Cold, warm and hot presses are available for use at up to 10,000 bar and at temperatures from -20 to 2,200°C. Applications Sintering of powders for the production of complex geometries with high resilience. (Plastic, ceramic, graphite, metal, etc.) Sterilization of food Pressure / temperature simulations Hardening of mechanical parts Elimination of natural porosities in raw metallic materials Pressing of sintered parts (carbides, steels, etc.)

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

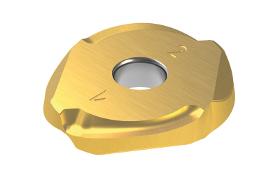

The milling cutters used during roughing in die and mold making have to continuously withstand high levels of stress otherwise process reliability and quality cannot be guaranteed. That is why the CopyMax® product family by LMT Kieninger has been specially designed to handle these extreme conditions. The patent-pending HQS (High Quality Sintering) production process and Nanomold Gold high-performance coating ensure high endurance during roughing and semi-finishing. The double-sided CopyMax®2 indexable insert has already convinced many customers with its up to fourfold increase in service life. The single-sided CopyMax®1 insert is now also available. Users can therefore select the appropriate model depending on to the requirements of the respective component. This definitely increases tool life and process reliability while simultaneous reducing handling.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

COD Sinter-HIP furnaces combine the dewaxing, vacuum-sintering and subsequent isostatic densification under pressure gas up to 100 bar of sinter parts made of hard metals or ceramics. COD furnaces optimize all the necessary process functions and combine them in one production equipment and process cycle in an optimal, fully automatic and reproducible manner. Applications: Vacuum- and pressure sintering of hard metal products, PM-high-speed steels and ceramics. Benefit for users: • Low operating costs due to low power and cooling water consumption • High product quality due to excellent temperature homogeneity in vacuum, during pressure gas injection and pressure sintering. • Rapid startup at user's site and productivity "from day one" due to complete pre-assembly and fully hot shop-test and TÜV-acceptance in the factory • Service and maintenance friendly design, high up-time

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

The SSH is a standardized vacuum-pressure sintering furnace for economic production of hardmetal (cemented carbide) parts. It combines the universal application of dewaxing (debinding), vacuum-sintering and isostatic pressing up to 60 bar overpressure in one process. Based on PVA TePla's leadership in production of Sinter HIP furnaces for hardmetal applications, the SSH furnace gives you a most affordable and economic access to this leading technology. Applications: Dewaxing (Debinding), vacuum-sintering, isostatic pressing Customer Benefits: • High product quality by excellent temperature homogeneity • Elaborated safety system for reliable and full-automatic operation • Short dewaxing and cooling times • Short installation and ramp-up times, all pre-tests and qualifications done at PVA site • Proven design and performance • Short delivery time due to pre-production • High cost effectiveness • High energy efficiency • Low gas consumption

Request for a quote

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

NKCG offers a complete portfolio of carbon-based products for vacuum sintering process of hard metals and ceramics.

Request for a quote

EXXENTIS

Switzerland

Porous aluminium is a high porosity noise insulation material / metal. Silencers made of porous aluminium serve for noise reduction / absorbtion for instance in pneumatic systems. When escaping from the pneumatic device into the atmosphere, compressed air causes noise levels that are unpleasant and unhealthy. This problem is solved if the air leaves the pneumatic device via a silencer/muffler. We are happy to offer you customized silencers in different form and shape according to your needs - cylindical silencers, silencers in plate and discs form, industrial silencers and mufflers for different applications. For the manufacturing of Industrial silencers / mufflers made of porous aluminium we do not use any cost-intensive pressing moulds as sinter technology needs, but conventional casting moulds. Our products made of porous aluminium have – thanks to innovative and relative simple manufacturing technology – an excellent quality-price rati

Results for

Sintered products - Import exportNumber of results

12 ProductsCountries

Company type

Category

- Sintering - steels and metals (3)

- Disks, magnetic (1)

- Heat treatment furnaces (1)

- Industrial tools (1)

- Magnets (1)

- Mechanical engineering - custom work (1)

- Metallurgy - machinery and installations (1)

- Precious metals, powder (1)

- Presses, hydraulic (1)

- Sintering machine tools (1)

- Steels and metals - machining (1)