- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- single source

Results for

Single source - Import export

BAMINA JEWELLERY

Turkey

Elevate your style with our Solitaire Bone Ring, expertly crafted to embody timeless sophistication. Each ring showcases a single, ethically sourced bone stone, set in a choice of fine gold or sterling silver. With its understated design and impeccable detail, this ring effortlessly complements any look, from casual to formal. Add a touch of natural beauty to your ensemble with our Solitaire Bone Ring collection.

Request for a quote

IGUS® GMBH

Germany

readycable® harnessed cables are ready-to-connect cables for use in energy chains®. As manufacturer and harnesser, igus® provides everything from a single source, thus reducing throughput times and the number of suppliers. The portfolio includes an extensive range of catalogue products, including cables harnessed according to manufacturers' standards and diverse industrial standards as well as individual singly or series produced components. Numerous types of cable of different qualities, with different approvals and with different certifications of conformity are available to choose from. All components are subjected to extensive quality checks and functional tests.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

MACK current collector trolleys are used in moving current consumers, such as cranes, suspended rail systems, or high rack vehicle systems. What are you considering? Where can we offer you support in system development? Our current collector trolleys, complete with carbon brushes and fittings, are guided by sliding plates or castors with bearings in contact-protected linear conductor lines. Our customers around the world include leading system suppliers who order customer-tailored current collector trolleys from MACK, ready to install from a single source. Of course, we can also produce any special type that you require, for example fast-running versions or double-current collector trolleys.

Request for a quote

WEBER GMBH & CO. KG, KUNSTSTOFFTECHNIK UND FORMENBAU

Germany

From the initial concept to a safe and reliable series delivery, our customers get everything from a single source. They benefit from our decades of experience in manufacturing interiors as well as exteriors for the automotive industry.

Request for a quote

TECHNO-COMPOSITES DOMINE GMBH

Germany

Within the chemical industry, systems can only seldom be optimised using offtheshelf solutions. Generally speaking, all TC structures are developed in accordance with DIN EN ISO 14122. Certification according to DIN EN ISO 90012015 confirms the excellence of our quality management. The pultruded GRP construction profiles from Exel Composites comply with EN 13706/E23. We advise you on site and can accommodate your wishes in terms of corrosionresistant access systems. We provide design, manufacture and assembly on site, all from a single source.

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

Electrical heat tracing systems are used in all industrial sectors in order to heat up products in pipelines and vessels to maintain temperatures or to avoid freezing of the product. This type of heating offers several advantages It is highly flexible and adaptable to fulfil the specific customer requirements and ensures the effective and economic utilization of the input energy. Our customers appreciate the high accuracy of temperature control and the low maintenance costs. We offer harmonized components, engineering, delivery and installation from a single source.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

This AWALIFT is also available in an extended design, the AWALIFT 7/3x2, which achieves a discharge head of 92 mWS, while the AWALIFT 7/3 achieves a discharge head of 46 mWS. We offer everything from a single source, from planning to installation. STRATE project engineers are experienced in turning your specialized requirements, such as conveying wastewater over large distances and high discharge heads, into first-class process solutions. Our patented separator system makes it possible to connect two circulating pumps in series.Tank: S235JR (St37-2) Draining towns with up to about 16,300 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with three separator systems Three centrifugal pumps and motors according to type

Request for a quote

MOOG GAT GMBH

Germany

The ROTOKOMBI system allows all rotary union and slip ring types to be combined. The result is a complete rotary transmission system from a single source, with perfectly matched interfaces. ROTOKOMBI systems ensure that an optimally adapted sealing system is available for any medium. For any type of electrical transmission a corresponding system is selected to ensure adequate reliability. Thanks to the modular design, individual components can be replaced, retrofitted or upgraded as necessary. All components are selected and combined to meet your specific demands, without limitations to the number of electrical poles, media or size. Special solutions such as ATEX/IECEx or certifications according to UL/CSA regulations are also available on request.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Due to the ever-increasing level of automation, coated rolls and rollers are now used in almost all production facilities. These rollers and rolls are used in a wide variety of applications (transport, finishing, cleaning, coating, drying, etc.). What is particularly important is the quality of the coating, which determines the service life of the roller and the processing process.We manufacture completely coated rollers, i.e. We provide you with the roller core made of aluminum, steel, etc. and the desired coatings (rubber, Vulkollan®, etc.) from a single source. We can also roughly pre-grind your rollers, finely grind them or even provide them with grooves.As a cost-effective alternative, we also offer you to have your rollers recoated by us. Here too we can choose between different coatings (rubber, Vulkollan®, etc.). According to the customer’s wishes, we can also pre-grind, finely grind or provide these rollers with grooves. We would be pleased to advise you!

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

ANSMANN AG

Germany

Planning a new development or a redesign of a rechargeable battery or charger? ANSMANN – Your partner from the initial idea through the planning, design, development and manufacturing stages and on to serial manufacturing. Based on your application and the requirements, we can guide you with professional advice for the selection of the correct cells, the capabilities of the necessary protective circuitry, compliance with standards and certification (as early as in the development phase), the first prototypes as STL parts and the first measurements. We can support you through all of the important steps towards your final decision. We can take on the design and manufacturing of the housing parts and the injection and stamping tools required for this. Single-source delivery and manufacturing guarantees optimum interaction between rechargeable battery, BMS and charger. The cells that we use are delivered by renowned manufacturers such as Panasonic, LG, Samsung, Sanyo, A123, Sony, etc.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

At OptiMel, you get everything from a single source to optimally use low pressure molding technology for high-quality electronics encapsulation. Thermoplastic hot melts are used as encapsulation material. Due to their range of properties, amorphous thermoplastic polyamide granules are predominantly used in low pressure molding. Thermoplastic polyolefins are also available for special applications, which are used whenever sufficient adhesion cannot be achieved with the preferred polyamides on the substrates used (e.g. cross-linked polyethylene). Due to different raw material combinations, the range of properties of these hot melt granules varies in terms of mechanical strength, operating temperatures and resistance to various media. The hot melt molding materials combine a viscosity spectrum that is favorable for the low-pressure process with a wide operating temperature range (-50 / + 150°C) and, in some cases, very good adhesive properties. Depending on the material

Request for a quote

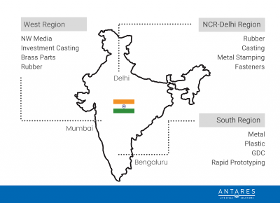

ANTARES LIFE CYCLE SOLUTIONS GMBH

Germany

Components in small volumes, replacement parts which are difficult to source or have even become obsolete, requirements and customer demands that fluctuate substantially (and are therefore effectively unplannable) All these are challenges in the day-to-day life of OEMs and TIER-X manufacturers in off-highway, commercial vehicles, mechanical engineering and many other industries when it comes to delivery performance towards end-customers. Our solution: for every case the most suitable manufacturing technology combined with our own experienced engineering team – everything from a single source. Technologies: Additive Manufacturing / 3D printing Casting Parts (sand casting, pressure casting and many more) CNC Parts Technical Plastics Parts Rubber and Elastomer Parts (gaskets) Assembly of Modules and Systems and many more

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Modernisation pays off: The average service life of industrial boiler systems is between 20 and 40 years. Many measures which previously were not possible or financially justifiable pay off nowadays after a very short period of time. Five good reasons to modernise your energy generating system: — Energy efficiency: Reduce operating costs and increase competitiveness — Supply reliability: Ensure reliable heating processes, flexibility of the energy source and system availability — Structural adaptation: Changed power demand, fuel change or Industry 4.0 integration — Climate targets: Protect resources, reduce emissions and produce sustainably — Laws, directives, requirements: Fulfill conformity For higher sustainability, energy efficiency, availability and operational safety. With modern project planning and modular system technology.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

When operating with green energy, the boiler allows your company to achieve a CO2-neutral steam supply. — Generate up to 7.5 t/h steam in a highly efficient way using just electricity – no combustion, no emissions — High steam quality, excellent dynamics, full flexibility — Reduced expenditure: No flue gas, no fuel supply — Application-specific design and particularly reliable operation — Smart boiler control and seamless system integration — System equipment and service from a single source

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The heating boiler UT-L offers high performance and is extremely compact. The design complies with the Gas Appliances Regulation. — Very high efficiency up to 105% for optimised energy costs — Compact design for easy positioning and effective use of heat — Flexible application and low return flow temperature of 50 °C possible — Specific control concept and optional real-time monitoring — Future-proof heat supply and options for CO2-neutral operation — Proven and durable Bosch system from a single source — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The various output sizes and temperature ranges up to 190 °C of the UT-M enable flexible operation for countless process heat and heating applications. — Efficient heat and process heat for low running costs and emissions — Compact design for easy positioning and quick heating — Flexible use for industrial, commercial and district heating applications with temperatures up to 190 °C — Project-specific control solutions and optional real-time monitoring — Complete system from a single source, low-emission or CO2-neutral customer-specific operation possible — Proven and maintenance-friendly construction for a long service life and reliability — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PATAZA PTY LTD

Australia

Guaranteed 100% pure organic Australian honey. This honey is single source - it is not a blend of various beekeepers. The honey is strained to remove any beeswax; it is not filtered. More varieties available.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Opacity tester indicates relative opacity of plastic film, paper, laminates, printed packaging and other materials. With a single pass of the light source through your material, the system measures relative light transmission on a scale of 0 to 100 Opacity Units, representing perfectly transparent to purely opaque materials, respectively. According to ISO 7686

Request for a quote

OCV ITALIA

Italy

ME1960 multiend roving represents a versatile solution for a largesurface of SMC (Sheet Molding Compound) components that require a combination of efficient processing, high mechanical, and aesthetic properties. EFFICIENT PROCESSING Easy unwinding and chopping, flat laydown, and uniform dispersion with low fuzz and static for large and/or semistructural part molding. ENHANCED PERFORMANCE Better wetout allows higher glass loading (up to 65% according to a 2016 single customer data source) due to excellent wetthrough and impregnation. This can be leveraged to further enhance the mechanical strength and stiffness of the composite part in complex structures. IDEAL COLOR (WHITE) FOR PIGMENTED PARTS Desirable product flow within mold at low shrinkage delivers a resinrich whitecolor surface aspect with lowporosity which facilitates good pigmentation or painting of finished parts.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

We consider your process as a whole and plan the conveyor technology for the entire facility together with you. In addition to all mechanical and electrical engineering, we provide complete mechanical and electrical manufacturing with assembly service. From chain conveyors, telescopic conveyors, roller conveyors to belt conveyors and fully customized conveying systems, we supply you with everything from a single source

Request for a quote

RUHLAMAT GMBH

Germany

Test systems and inspection systems form an integral part of most of the automated solutions we employ. Each assembly process is usually followed by an inspection process so that the highest quality requirements can be satisfied. Both laboratory as well as stand alone or inline series inspection systems (EOL) have already been widely implemented by ruhlamat. Inspection results (product/process data) are documented in individual or customer-specific databases (traceability). Seamless traceability of product and process data Inline process control and monitoring Efficiency through timely trend control 100% inspection

Request for a quote

MECHASYS GMBH

Germany

Samples, prototypes and small series made of sheet metal Laser cutting, embossing and bending or punching including electroplating. Prototypes and small series - everything from a single source! We manufacture your individual sample parts, prototypes and small series mostly without any proportionate tool costs. This means that we are very flexible, efficient and cost-effective even with small quantities - in extreme cases from a quantity of 1. This is made possible by our modular bending kit. Everything from a single source: • raw sheets in stock • Laser fine cutting also from pre-punching tape using camera calibration technology • Embossing, bending, folding, pressing • Punching of functional areas • Progressive punching of medium quantities, depending on economic efficiency • Module assembly • CNC laser welding • Complete or partial electroplating by partner.

Request for a quote

SCHOCK GROUP

Germany

We offer our customers an "all-in-one" service at the highest level: from profiles to assembly, right up to integrated system solutions. SCHOCK has extensive expertise in the assembly and manufacturing of complex assemblies. As a result, our customers can source a fully assembled assembly from SCHOCK instead of multiple individual components. They benefit from our manufacturing facilities with experienced teams in assembly, surface finishing, quality assurance, and logistics. Service Overview: Assembly of complex assemblies Joining, welding, connecting Punching, embossing, and bending technology Surface finishing Integrated functional testing Procurement of purchased parts Packaging and logistics

Request for a quote

SCHOCK GROUP

Germany

We manufacture complex assemblies for our customers, incorporating process-controlled assembly processing along with comprehensive supply chain management. We offer our customers a comprehensive procurement, manufacturing, and delivery service of the highest quality. You benefit from our process-controlled assembly processing through the production and delivery of complex assemblies. Our service offerings include, among others: Assembly of kinematic components Manufacturing of complex assemblies Stable supply chains from European production Centralized logistics Complete value creation from a single source

Request for a quote

FILLTECH GMBH

Germany

Filling plants and bottling from a single source Use our services and lay back. At Filltech, we can ensure gas filling services at custom-made aplications maintained and controlled at our premises. Gases for food and industrial applications, noble and special gases and different gas mixtures are filled accurately in different cylinders or containers. CO 2 cylinders for soda If you would like to know what tailor-made systems can achieve andhow many benefits they provide, we like to share our customer cases with you. In the food industry, for example, we cooperated with a soda supplier. We developed and manufactured a fully automatic filling plant. Up to 1,000 cylinders per hour can be drained, flushed and refilled automatically. An integrated leak test, a 100-percent weight loss and the acquisition of all the highest quality padding ensure a high quality process. Special software for monitoring and documenting the production parameters, developed by Filltech, ensures all statutory proc

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Tool making We stick to the "single source supply" principle. Marchtrenk is not only the center for the development of products. Here we design and produce the molds for injection molding products exclusively in our own tool making department. Our expertise is concentrated entirely here at our HQ. This makes us independent and we can react in a flexible manner. You do not have to worry whether your tool has been calibrated properly to produce good components – we do that for you. We supply you with perfect silicone or compound parts.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Enables several air lines to be taken simultaneously from one supply line! Just push in the plug to socket for simple and secure connection! Multiple outlets are available from single air supply source. Choose from the 2outlet type (Model 200T), the 5outlet straight type (Model 200L) and the 5outlet star type (Model 200S) to suit your application.

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec offers complete production systems for manufacturing long-fiber reinforced thermoplastics (LFT) in pellet form and as UD tapes (unidirectionally reinforced tapes) as well as impregnated fiber strands and profiles. The system works extremely flexibly and is designed for variable formulations and high throughputs at a production speed of 50 m/min. We deliver an LFT system design customized to meet the respective customer requirements, all from an single source – from material development, to testing and commissioning on location at the customer‘s premises.

Request for a quoteResults for

Single source - Import exportNumber of results

104 ProductsCompany type

Category

- Locks (27)

- Hinges (21)

- Automation - systems and equipment (7)

- Boilers, industrial (2)

- Boilerwork (2)

- Fertilizers and soil conditioners (2)

- Honey (2)

- Palletising machinery (2)

- Plants & Fertilizers (2)

- Boilers, cast iron (1)

- Bridge cranes (1)

- Building materials, manufacture - machinery and equipment (1)

- Chimneys, industrial (1)

- Construction, industrial - contractors (1)

- Coupling, pneumatic (1)

- Electric cables (1)

- Electronic cards (1)

- Engineering - industrial contractors (1)

- Engines & Parts (1)

- Fabrics for technical use (1)