- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silica sand

Results for

Silica sand - Import export

B*BATI

Spain

Dry cement mortar composed of aggregates, silica sands and special additives which give it optimum workability and adhesion.

Request for a quote

OEN CHEMICALS GMBH

Austria

Sodium Metasilicate Anhydrous is an inorganic substance, a stable chemical made of silicon, sodium and oxygen. This chemical is made with the melting of silica sand or quartz with sodium carbonate at high temperature to create glassy substances which are grind further into fine powder. Sodium Metasilicate Anhydrous must be kept in dry, cool and well ventilated places as it can react with acids and oxidizing substances etc., to produce heat and fumes. Sodium Metasilicate Anhydrous is mostly used as a builder, surfactant and corrosion inhibitor in various industrial applications. Sodium Metasilicate Anhydrous is used in a wide range of industrial chemicals such as detergent and in the cleaning industry as a cleaning agent and builder in laundry and dishwashing detergents. This chemical is also used in the construction industry to improve the strength and durability of cement and concrete compositions

Request for a quote

TITAN MACHINERY

United Kingdom

A sand-lime brick making machine is a specialized piece of equipment designed for the production of bricks made from a mixture of sand, lime, and other additives. These bricks are also known as silica sand bricks or sand-lime bricks and are recognized for their excellent quality and durability. Sand-lime brick making machines are widely used in the construction industry to produce bricks that are known for their strength and resistance to environmental factors. These bricks find applications in various construction projects, including residential, commercial, and industrial buildings. They are valued for their durability and suitability for both load-bearing and non-load-bearing walls.

Request for a quote

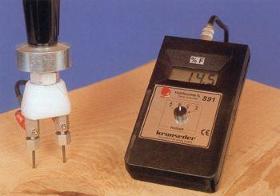

KRONSEDER TROCKENTECHNIK GMBH & CO. KG

Germany

Digital wood moisture measuring equipment We are not only specialists for wood drying, but also your partner to contact for anything related to moisture measuring technology. Our modern, innovative company combines moisture measuring technology, control technology Our digital moisture measuring equipment with temperature compensation accurately measures: Sawn timber, chipboard, veneer, sawdust, wood chips, wood shavings, concrete, aerated concrete, tiles, screed, plaster, silica sand (sand up to a maximum of 20 %), lime plaster, concrete, paper, cardboard and also textiles and drying technology into a complete coordinated offer.

Request for a quote

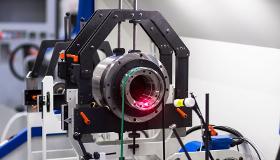

CIMAT

Poland

In addition to conventional horizontal balancing machines on a bed, we offer compact balancing machines, which correspond to ergonomic requirements of every customer. The greatest advantage of compact balancing machines is the possibility of easy placement—embedded vibration insulators do not require foundations. As such, our compact machines occupy a small area in comparison to conventional balancing machines on a bed. This is made possible by a guard coupled with the balancing machine body—these guards do not occupy additional square meters of area. In spite of their small dimensions, these compact balancing machines have a robust body with silica sand filling to dampen vibration. As a result, our machines are capable of very accurate measurements and they are less sensitive to outside disturbances. Main features Using an appropriate machine design and a suitable safety guarding machines can also be used for highspeed balancing Permanent calibration and rotor specific calibration

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DEMIRHAN

Turkey

At first,the ground of field is hardened for leveling by steamroller or ground roller. For ground concrete,the place is excavated by JSB or etc. The concrete is poured to the excavated area. 25cmx50 cm molds are placed. The reinforcing bars are placed into the molds. Before pouring the concrete,anchor pipes are put amoung the reinforcing bars.After pouring the concrete,the gravels are poured up to the zero point as No:4 , No:3, No:2 sequintally.76mmx3mm thick h:600 cm verizontal pipes are placed.After placing all pipes,60mmx2mm thick horizontal pipes are welded to the vertical pipes. Vertical and horizontal pipes are painted with anticorrosion paint. Over the anticorrosion paint,RAL 6005 paint is applied. Then the area is enclosed with 50cmx50cm sized 3,50 mm thick PVC wire mesh. 55 mm thick artificial turf is roll outed. Silica sand and sbr granuls is applied into the turf. Sport equipments,goalposts,top covering mesh,lighting projector and projector posts are installed.

Request for a quote

FORVAC SERVICES LTD

United Kingdom

Forvac is the proud manufacturer of our own British designed and built heavy duty FVP & FV electric, diesel, fixed or portable industrial vacuum range. Having our own design and development team we also, manufacture bespoke industrial vacuums and systems providing complete tailored solutions, designed to suit the application and customer requirements. After the initial on-site consultation, our design team and project manager will determine and provide, the most cost effective solution for the application, whether it be a standard or bespoke. Forvac designs, builds and installs from start to finish, using our own design team and installation engineers, ensuring costs are kept to a minimum. The savings don’t stop there, Forvac is also the distributor for Lajac pipework ducting systems, keeping our prices even more competitive. Whether it’s supplying a new machine, a new or modified ducting installation or a complete system, we would be more than happy to help.

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® M-Class constitutes the optimum solution when many cut points in the fine and very fine range are required and, in addition to that, most accurate cuts are of decisive importance. There are various fields of application that exist for the linear motion swinger. To be precise, the screening system can be employed for the classification of industrial minerals, food, chemical products, ores and metals. The dynamic loads of the machine are reduced to a minimum by an isolating frame. As a result the vibrations transferred into the structure can be prevented. Depending on the required application, the exact adjustable rotation speed and amplitude ensures an optimum screening result. Accelerations are possible between 2 g for the production of abrasive materials - or up to 4,5 g for the dry mortar or silica sand industry. The multiple-deck screening machine NIAGARA® M-Class is offered in eight different sizes, the number of decks and technical specifications depends on the...

Request for a quote

MINFORM UK

United Kingdom

Floor Plank is an innovative wood substitute product made from superior Portland Cement, Silica Sand, and Special Cellulose Fiber using high standardized processes (Autoclave Process).

Request for a quoteResults for

Silica sand - Import exportNumber of results

10 ProductsCompany type

Category