- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sieve mills

Results for

Sieve mills - Import export

PARSMEGA MAKINA

Turkey

It ensures the classification of the ground product in a clean and orderly manner, thanks to the freely swinging body and the crates of different sizes in each passage within the body. After being sieved and homogeneously separated, the product in various proportions is automatically directed to the outlet channel through the channels in the frame, the channels between the frame and the channels in the main chassis, and is discharged outside the outlet pipes through control pipes. The surfaces of the cases are covered with formica. The outer covers of the passage are insulated, thus preventing flour particles from leaking out. The product enters the first case as one or two batches from the entrance above the passage and flows along the passage height of all cases. By placing spacers between the frames of the main frames, the product output volume increases, accumulation

Request for a quote

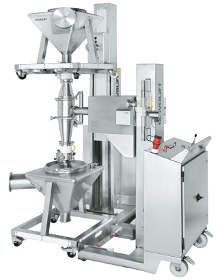

SERVOLIFT GMBH

Germany

The broad applications spectrum of SERVOLIFT milling and sieving equipment leads to flexible and user-friendly solutions in combination with handling systems. The areas of application stretch from controlled sieving in order to remove contamination from raw materials to fractionation, calibration to deagglomeration. Sieve mills, vibration sieve machines or inline sieve equipment in combination with mobile or stationary lifting systems provide a flexible, compact and easy-to-clean system. Size as needed Technical description Stainless steel or cGMP/FDA compliant designs Use as sieve mills (cone mills), hammer mills, oscillating sieve mills Various throughput depending upon the product and particle size Lifting height can be customized Broad control designs, from simple microcontrollers with digital displays to PLC controls Explosion-protected designs in adherence to Atex Zone 1/21 and 2/22.

Request for a quote

ROBINSON CO.

Turkey

This hammer mill grinds easily raw materials which are dry and lle dampens fine. For this reason it is used in food industry.The body is of steel and weld construction. The hammers are on the rotor which turn a mill. The rotormill turns in the strong ball thrust. The hammers are made of hardened steel.It is designed turn free.The sieve is on the hammer mill and it is changed easily without stopping the rotor. Motor is connected directly to the coupling. The body of hammer mill is mounted on the same chassis. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

SERVOLIFT GMBH

Germany

Before solid products, agglomerates or clumps can be sieved or calibrated, these must be broken up or crushed. Suitable materials are available to break up the product in drums with the right SERVOLIFT systems. Pinpoint pressure Technical description Sequence: Drum crusher: Products solidly in drums are broken up in drum crushers in order to discharge them. Primary crusher: Large fragments are crushed with the primary crusher into fist-sized lumps. Clump crusher: Larger clumps are broken up by the clump crusher for the sieve mill to a workable size. The machines can be combined with one another, or be used on their own. A protective device is adapted to the relevant use case.

Request for a quote

SERVOLIFT GMBH

Germany

These types of machines are used for a variety of applications when combined with process machines. The use of cone mills, hammer mills, vibration sieves, sifters, mobile for various areas or stationary. The broad applications spectrum of these devices can be seen in weighing for raw materials preparation or granulation for calibration, to name two examples. The take-up system is designed and adapted depending upon the process machines and the specified runs. Take-up of various additional devices Technical description cGMP-compliant design Mobile or stationary or combinable for high flexibility Adapted take-up system, depending upon the process machines Variable, adjustable lifting function - for mobile units with telescoping designs for low drive-through heights Function extensions through the integration of tilting and pivoting functions Various containment designs, such as low-dust connections up to high-containment solutions Extensive control designs, depending upon...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PURA AGRO PARTNERS PRODUCTION SRL

Romania

Walnut flour is a by-product of cold pressing after obtaining walnut oil, then milled and sieved through various screens, resulting in a final product with high protein concentration

Request for a quote

PURA AGRO PARTNERS PRODUCTION SRL

Romania

Hemp seed flour is hemp seed cake (the by-product of cold pressing after obtaining hemp seed oil) milled and sieved through various screens, resulting in a final product with high protein concentration.

Request for a quoteResults for

Sieve mills - Import exportNumber of results

8 ProductsCountries

Company type