- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- siemens controllers

Results for

Siemens controllers - Import export

RIMA HEATING SYSTEMS

Turkey

Corrosion resistant, light Aluminium heat exchanger Efficiency up to %108,5 Modulation ratio 71 12 different capacities (830 kW to 3250 kW) Cascade system with 16 boilers Workıng pressure 6 bar High combustion performance with low exhaust emission Different zone controls with Siemens control panel Compability with Open Therm ve BUS comunication systems Easy to use and maintenance

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control system - select, click, control... Travel distances, positions, speeds, operating times - easily defined with the new igus® web-based control system for drylin® E linear systems. - No software or app installation necessary, fast commissioning - Control possible via smartphone (browser), tablet or laptop - Simple and intuitive user interface, control system set up in just a few minutes - Compatible with numerous industrial controllers (e.g. Siemens S7/Beckhoff) - For DC, EC and stepper motors - Cost-effective

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

PRESSTA EISELE GMBH

Germany

High performance automatic circular saw for aluminum and non-ferrous metals Fully automatic operation Infinitely adjustable speed control of the saw blade engine Material and saw feeder movement through servo driven ball screw spindle 2 axis CNC control Siemens S7 with 7” touchscreen Cutting range: up to 205 mm height and up to 400 mm width Rest-piece length as short as 55 mm (depending on profile) Machine can use carbide (TCT) or PKD blades diameter 650 mm (smaller diameter upon request) Automatic kerf widening to reduce scratches Individually controllable clamping pressure Motorized material feed with servo driven ball screw Pneumatic material clamps individually adjustable Positioning of the vertical and horizontal clamps by hand-wheel Cut off lengths of up to 5000 mm are possible by reversing the material feed up to 5 times Floating material feed to reduce material abrasion Feeder length of 1000 mm Simple exchange of saw blade, accessible from the front Saw blade feed is...

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Reformer R70i has been developed for producing dense dry ice blocks in various sizes by compressing dry ice pellets. Be it in combination with an existing or with a new dry ice pelletizer, the ASCO Dry Ice Reformer R70i is a very convenient tool to complement the dry ice pellet business with dry ice blocks. The compact machine is driven by a powerful and unique hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC. A Siemens touch screen provides good overview and easy operation, a comprehensive monitoring, easy maintenance and optimal service planning. An integrated production control system allows to define and supervise the amount of blocks or weight to be produced.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P28i is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 280 kg/h (617 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P28i is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P15(i) is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 150 kg/h (331 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As an optional model of ASCO's iSeries, it can be equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Whether for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P15(i) is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2500 Variospeed is a fully automated filling, foil application and sealing machine, suitable for creamy to liquid filling media for plastic, tin or glass containers. Available performance versions: 2.500 units/h, 3.000 units/h or 3.500 units/h. all gearboxes are maintenance-free: Lenze main drive, Atek gearbox, Miksch stepping gear various cams on drive shafts of the gearbox: filling cam, control cam for valves, pre-sealing cam, lever arm for driving the metering pump and dispenser drive shafts with prockets for chain drives central lubricating system 8-up turntable with mechanical overload clutch backlog detector and monitor for incoming and outgoing containers filling unit with turntable metering unit 40 liters filling funnel dispenser with pre-sealing thermal sealing unit (conductive) integrated conveyor belt central, stepless height adjustment of conveyors and guides by a handwheel integrated SPS control system Siemens S7

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4 SIZES AND LOTS OF POSSIBILITIES! THE SFZ SERIES ESPECIALLY SCORES WITH STRONG PERFORMANCE. Starting from the four basic models of the SFZ series; We offer modular equipment variants, depending on performance requirements. Completely in the spirit of FIT 2 TASK. In order to guarantee individual performance, the SFZ machines are equipped with the latest generation of Heidenhain iTNC640 controls as standard. SIEMENS 840D SL is optionally available as an alternative, depending on your requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIMA HEATING SYSTEMS

Turkey

Corrosion resistant, light Aluminium heat exchanger Efficiency upto %107 Five different capacities for Ongas 300 (70, 95, 125, 155, 190* kW) Nine different capacities for Ongas 600 from 230 kW to 850* kW Cascade system with 16 boilers Workıng pressure 6 bar High combustion performance with low exhaust emission Different zone controls with Siemens control panel 17 modulation ration Compability with Open Therm ve BUS comunication systems Low noise level Easy to use and maintenance

Request for a quote

RIMA HEATING SYSTEMS

Turkey

Corrosion resistant, light Aluminium heat exchanger Efficiency upto %109 Five capacities options (70 , 95, 125, 155, 190* kW) Cascade system with 16 boilers 17 modulation ration Workıng pressure 6 bar High combustion performance with low exhaust emission Different zone controls with Siemens control panel Compability with Open Therm ve BUS comunication systems External chimney flap Low noise level Easy to use and maintenance

Request for a quote

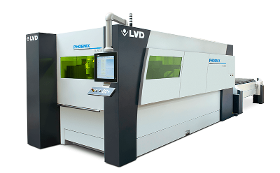

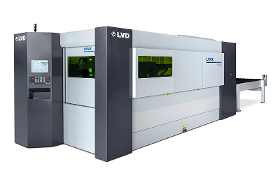

LVD

Belgium

The Phoenix fiber laser cutting machine is an all-around performer. It has the flexibility to expertly cut standard steels and non-ferrous materials in a range of thicknesses and combines high machine dynamics, intuitive machine operation, and advanced automation options to maximize productivity no matter the application. The inherent benefits of fiber laser technology make Phoenix cost effective to maintain and operate. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Processes different sheet thicknesses without manual intervention Advanced cutting head handles thicker materials “On the fly” cutting in light gauge material Integrated Siemens CNC control and drive system offers high reliability TOUCH-L touch screen graphical user interface control is intuitive and simple to use Automatic shuttle table maximizes uptime PERFORMANCE-ENHANCING OPTIONS CADMAN-L programming software MOVit Automation: TAS, WAS, Compact Tower

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

A device for emergency ventilation and intensive care that allows to control and monitor the key parameters of ventilation. It has been designed to work continuously and intensively. It has different ventilation modes, giving it great versatility to treat patients in different phases of invasive ventilation. Control by PLC SIEMENS with a very simple and intuitive interface for maximum security. RESPIRA has real-time measurement sensors for key parameters for respiration, respiration graphs.

Request for a quote

LVD

Belgium

TL 8525 is a high-capacity tube laser cutting machine designed for top productivity. It handles lengths up to 8500 mm and diameters up to 250 mm round or square. The TL 8525 comes equipped with leading-edge features, including a 45-degree tilt-axis cutting head with NC-Focus, 6-position front loader, 2 kW IPG fiber laser, and a large X-axis cutting head range of 1190 mm to maximize material usage. KEY FEATURES Accommodates tube and profile lengths up to 8500 mm, diameters up to 250 mm High-performance cutting head with NC-Focus and bevel function +/- 45 degrees Magazine style 6-position automatic tube load system Leading edge detection for variable tube lengths Automatic bow detection and compensation system Automatic twist compensation system Outfeed tube support with accompanying conveyor table Siemens CNC control is PC-based with touchscreen PERFORMANCE-ENHANCING OPTIONS 4 kW fiber laser source 6100 mm outfeed extension Part evacuation conveyor Automatic weld seam detection

Request for a quote

LVD

Belgium

YSD LaserONE provides the key benefits of fiber laser cutting technology but eliminates the extras that increase machine cost and complexity. The LaserONE fiber laser cutting machine is designed for dependable performance and ease of use, and provides a quick return on investment. LaserONE is designed, manufactured, sold and serviced by LVD, backed by the LVD worldwide service and support network. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass Cutting head with NC focus, automatic focal adjustment and crash protection Designed for easy access to cutting table and scrap containers PC-based Siemens CNC control, servo motors and drives PERFORMANCE-ENHANCING OPTIONS Load-Assist automation in load-only or load/unload configuration MODELS YSD LaserONE 3015

Request for a quote

LVD

Belgium

COST-EFFICIENT FIBER LASER CUTTING MACHINE The Lynx allows easy entry into fiber laser cutting. With a modest investment, you can benefit from the flexibility and productivity of fiber laser technology. Cut ferrous and non-ferrous materials reliably with excellent cut quality and at three times the speed of a CO2 laser, achieving low per part cost. Enjoy high uptime with a virtually maintenance-free laser source, high wall plug efficiency, and very low operating costs. KEY FEATURES Processes ferrous and non-ferrous materials, including copper and brass IPG fiber laser source is virtually maintenance-free High wall plug efficiency of 40% Integrated Siemens CNC control and drive system ensures high reliability Automatic pallet changeover for efficient sheet loading and unloading in just 35 seconds PERFORMANCE-ENHANCING OPTIONS MOVit Automation: Load-Assist CADMAN-L programming software MODELS Lynx FL-3015 Lynx FL-4020

Request for a quote

MICROCYBER

China

It's very popular that our pressure and temperature measurement transmitters in oil and gas market , and HART modem is essential basic equipment. For some customers who want to connect two different industrial networks, we provide a cost-saving solution that gateways equipment. It basically realizes full communication, for Modbus, HART, Profibus, FF and DP. G0310 Modbus to HART Gateway, designed by Microcyber Corporation is a gateway device for Modbus-RTU protocol and HART protocol. As Modbus master, G0310 Modbus to HART Gateway communicates with devices that have Modbus-RTU communication function via RS485 interface. It can convert device data to HART device variables output, and it also supports 4~20mAcurrent output. Connect different control systems (Siemens, Emerson, Schneider Electronics, ABB, Yokogawa, Rockwell, etc.)

Request for a quote

MICROCYBER

China

1. A simple way to transparently transmit I/O data between two networks 2. Connect different control systems (Siemens, Emerson, Schneider Electronics, ABB, Yokogawa, Rockwell, etc.) 3. Support mainstream process industry communication protocols (Profibus DP, Profibus PA, HART and Foundation Fieldbus) 4. Support DD file, you can quickly configure parameters 5. 1-year product warranty from the date of shipment For our 4-20mA current converters, they are very popular and can help most of clients to savecost. 1. Transmitter for connecting analog signal to Fieldbus/Fieldbus signals to analog signals 2. Support 4-channel 4-20mA analog current input/output 3. Pass the FF H1 protocol interoperability test of FCG 4. It can pass the interoperability test of PNO's PROFIBUS PA protocol 5. High precision (normal temperature ± 0.05%), low temperature drift

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

Results for

Siemens controllers - Import exportNumber of results

71 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (14)

- Laser - cutting and welding machines (5)

- Bending machine tools (4)

- Cooling and lubrication pumps (3)

- Foundry machines - centrifugal (3)

- Robotics (3)

- Boilers, cast iron (2)

- Bottling and filling - machinery and equipment (2)

- Forming, rubber - machinery (2)

- Package stamping machinery (2)

- Potentiometers (2)

- Adjustment - machine tools (1)

- Cardboard and cardboard products - processing machinery (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Concrete mixers (1)

- Concrete, ready-mixed (1)

- Cutting - steels and metals (1)

- Electric transformers, converters and rectifiers (1)

- Flexography - machines (1)

- Flowmeters (1)