- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sharpening - machine tools

Results for

Sharpening - machine tools - Import export

FERNITE OF SHEFFIELD LIMITED

United Kingdom

A blunt blade “pushes” paper instead of slicing it, resulting in poor quality edges, tearing and shredding paper when cutting. To achieve faultless quality of cut paper it is important to regularly check and sharpen the blades of mechanical paper cutting guillotines.

Request for a quote

FERNITE OF SHEFFIELD LIMITED

United Kingdom

Our granulator knife sharpening service is provided from Fernite’s ISO 9001 certified factory in Sheffield. Our professional and experienced knife sharpening experts look after your knives as they would if they were sharpening a brand new knife. We recommend sending your granulator knives to us as a complete set, so we ensure that the knives tolerances required by the granulator manufacturer are maintained. Please let us know what type of material you are processing, as thinner materials often require tighter blade tolerances. We have the capacity to sharpen blades of up to 6 metres. We are using less rigid porous grinding abrasives for minimal-loading and cool surface sharpening. Therefore, your knife doesn’t produce overheat and doesn’t become more brittle as a result. Correct equipment for sharpening either Carbon, Alloy, or even Tungsten Tipped granulator knife. On custom request, a Granulator Knife can be finish ground to profile.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

An efficiently sharpened saw blade is essential for productive and safe work processes. Tyrolit offers an extensive range of grinding tools for various saw blades, including chain saws, circular saws, band saws, and gang saws. Our abrasives are precisely matched to different grinding machines and tooth pitches for optimal sharpening results, featuring vitrified-bonded grinding wheels and resin-bonded diamond and CBN wheels for special applications. Tyrolit’s decades of experience are evident in our tools' grit qualities and innovative bond systems, ensuring optimal cutting edge quality. Our grinding tools for automatic chain saw sharpening machines promise extended service life and perfect tooth base radius matching. We also offer resin-bonded diamond wheels for special applications and CBN tools for grinding HSS and high-alloyed steels.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The BGS product line consists of machines designed for the sharpening of flat and round broaching tools found mainly in the automotive and aerospace industries. Design and programming of the BGS is based on many years of manufacturing experience and knowledge of the tool industry. The BGS series signifies not only a machine concept but also a complete technological package consisting of machine and competence in the tool manufacturing arena. The machines of the BGS series are specifically designed for the sharpening process. The design concept with high dynamics and adapted grinding spindle allow the efficient and economic sharpening of broaching tools. An onboard measuring device probes the tooth root and cutting edge to determine the tooth pitch.

Request for a quote

EMSIL TECHTRANS SRL

Romania

Retrofit your machines to enjoy the modern age

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Description: •Precision machined components, Machining service, CNC precision machining, Stainless steel precision machined parts manufacturer •Material to process: aluminum, stainless steel, carbon steel, brass •Precision: 0.010-0.002mm •Equipments: CNC lathe, processing center, miller, cylindrical bore grinder, surface form grinder, punching machine, etc. •Surface treatment: zinc, nickel, anodized, polishing •Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. •We are able to supply Precision machined components, mechanical parts machining, surface treatment such as anodize and plating according to our customers’ requirement. •Packaging details: inner plastic bag, outer standard carton box •Delivery time: 25-35 days Notes: we manufacture precision machined components in compliance with customer’s designs. The products are shown here ony to present the

Request for a quote

NINGBO TOWER INDUSTRY CO.,LTD

China

Tower is a group of manufacturing facilities, offering one-stop solution for quality mechanical products with total lower cost in China. We can supply a full-range of metal products, such as sheet metal fabrication, cnc machining parts, casting parts, especially assembly parts. Product market range cover auto industry, medical industry,agricultural machinery, sport industry and so on. Because of our complete equipments, we are very suit for making all kinds of Assembly Parts. All of our products are customized by customer's drawing. Please feel free to send us your drawing or sample to customize!!!

Request for a quote

INGENIERIA IRADI S.L.

Spain

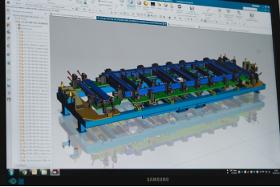

Our team of engineers thoroughly researches each project and designs the most appropriate solution for each customer. The technical office works in accordance with the needs of the customer or independently to meet a stated requirement. We offer complete solutions from design, manufacturing and quality control to on-site commissioning. We have a flexible structure, a dependable supplier network, technical training, and in-depth project knowledge. Our highly qualified technical department works with advanced 3D design programmes and we optimise our designs by means of finite element calculations, eliminating uncertainties and ensuring the correct functioning of each application.

Request for a quote

INGENIERIA IRADI S.L.

Spain

Ingeniería Iradi also designs, develops and manufactures equipment and special machines as well as conducting engineering studies and implementing automation proposals for repetitive manufacturing processes. We design the necessary equipment to facilitate the manufacturing, handling and assembly process We design and manufacture different types of equipment: - for the welding process - for verification and control - for holding - for turning - for detection - for assembly and calibration We have qualified personnel with extensive experience in the assembly and integration of various components and subsystems, and we collaborate closely with entities that specialize in electrical and electronic systems.

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

CAJHEN, D.O.O.

Slovenia

We sharpen cutting tools on 5-axis CNC machines, restoring the efficiency of used tools to that of a new tool. We are sharpening tools of all brands and shapes.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Each our component is individually handled in complete care and tested with the latest measuring devices - Mitutoyo. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] X-PRO series is for milling carbon steel, low alloy steel and cast iron. It is optimized for roughing by applying a new shape cutting edge for reducing cutting force and improving wear resistance. [Product Specification] Flat end mill : D3 ~ D16 (2Flute, 4Flute) Roughing end mill : D3 ~ D16 (3Flute, 4Flute) [Product Model] Flat : 2XPE, 4XPE, 4XREV, 4XPEV Roughing : 3XOE, 4XOE [Product Use] * X pro series is suitable for Roughing by chip breaker and to cut HRC below 50. * Strong wear-resistance by adapting X-pro coating. * Special design of cutting edge minimizes fracturing. * Excellent work surface by deep ship pocket.

Request for a quote

INOVER SARL

France

More than 30 years of experience in producing special carbide cutting tools, our professional team are ready to help you to solve the cutting tools problems.

Request for a quote

HAN SONG M&T

South Korea

[Product Description] S-PRO series is mainly used for cutting difficult-to-cut materials such as stainless, titanium, nickel and hastelloy in the aerospace field. A deep chip evacuation space of the S-PRO helps to cut difficult-to-cut materials, which facilitates chip evacuation and provides excellent surface finish. [Product Specification] Flat end mill : D1 ~ D20 Ball end mill : D3 ~ D20 C/R end mill : D1 ~ D20 [Product Model] Flat : 4SUE, 4SUEA Ball : 4SUB C/R : 4SUR, 4SURA [Product Use] * The cutting edge type of S pro series is unequal flute and it is suitable for cutting difficult to cut materials like alloly steels, stainless steels, Titianium, Inconel etc. * 4SURA, 4SUEA are specialized to cut Inconel. * Strong wear-resistance by adapting S-pro coating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EZSO, LLC

Russia

With our equipment you can make flight screws (feathers) up to 50 mm thick of any geometry and from any steel grade. The equipment is fitted with modern CNC control and software, which allows you to maintain accurate repeatability and ideal geometry of the flight screws. SPECIFICATIONS Overall dimensions of the press, L/W/H - 3200 mm / 1350 mm / 1500 mm Overall dimensions of the control unit, L/W/H - 1000 mm / 800 mm / 1650 mm Unit weight ready-assembled - less than or equal to 8000 kg Working pressure in the hydraulic system - 21 MPa Maximum pressure in the hydraulic system - 25 MPa Nominal press power - 100 tons Maximum short-term power - 110 tons Mains voltage - 380 V Power consumption - 22 kW Outer diameter of the coil - not limited Maximum flange height - 680 mm Maximum flange thickness - 2 mm - 50 mm Maximum flange pitch (with standard equipment) - unlimited

Request for a quote

BOGRAMA AG

Switzerland

High-performance drum feeder with low feed height for comfortable working. With a capacity of up to 20,000 cycles/h, the TA 20 is also deployed for the small folds of rotary printing sheets.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer table for inline configuration of BSR 550 Servo with machines interfaced upstream such as cross cutters and digital printing machines.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

BOGRAMA AG

Switzerland

Simple, cost-effective delivery with fixed height.

Request for a quote

BOGRAMA AG

Switzerland

The BSM 750 Servo with integrated front trim lends the booklet its final form. Front trim, head and foot trim, and blank separation are performed in one operation.

Request for a quote

BOGRAMA AG

Switzerland

Where punch force is crucial. Fitted with a high-performance servo drive, capacity rises to 12,500 cycles/h. High punch force for die-cutting (to max. 4 mm) High-performance 5kW servo motor Controllable cutting speed Available in two working widths.

Request for a quote

BOGRAMA AG

Switzerland

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

BOGRAMA AG

Switzerland

The most universal and most sold model by far for the mid capacity range to 10,500 cycles/h. Simple operation from touchscreen Integrated controller for infeed hole punching Available in two working widths.

Request for a quoteResults for

Sharpening - machine tools - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Cutting - machine tools (16)

- Machine tools - metal machining (11)

- Punching machine tools (7)

- Sharpening - machine tools (3)

- Drilling - machine tools (2)

- Adjustment - machine tools (2)

- Machine tools, metal machining - parts and accessories (2)

- Grinding - machine tools (1)

- Bellows - machine tools (1)

- Folding machine tools (1)

- Industrial sheet metal work (1)

- Lapping - machine tools (1)

- Machine vision system (1)

- Milling - machine tools (1)

- Sharpening - steels and metals (1)