- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- servomotors

Results for

Servomotors - Import export

KENDRION (VILLINGEN) GMBH

Germany

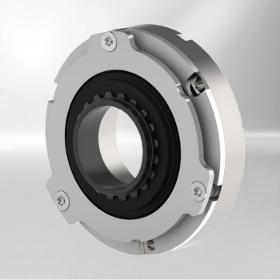

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

SCHNELL SPA

Italy

Rotor type wire straightening machine for the production of cuttosize wires up to Ø 12 mm (#3). Driven by digital electric servomotors. Max pulling speed 160 m/ min (525 ft/ min) High speed cutting unit with brushless (less than 0.1 sec) Web Teleassistance Available versions Fixed cut with adjustable backstop length for a maximum cutting precision (± 0.5 mm). Rotating cut system with automatic measurement via encoder for higher productivity (± 0.5 mm/m).

Request for a quote

SCHNELL SPA

Italy

Bidirectional automatic stirrup bender for the production of stirrups and shaped wires both from bars (up to Ø 22 mm #7) and from coils (up to Ø 16 mm #5). The lower bending unit performs downward bends. Driven by electric servomotors. These automatic stirrup benders are equipped with Max. pulling speed 100 m/min (330 ft/min) External and internal straightening unit Semiautomatic cycle for shaped wires with bends on both ends Barholding clamp for downward bends Virtual mandrel for the upper processing unit Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Stirrup bender and bar shaping machine from coil with 2 bending heads, allows to produce stirrups and shaped wires with bends at both ends using wires up to Ø 25 mm (#8). Driven by electric servomotors. These automatic stirrup benders and bar shaping machines are equipped with Max. pulling speed 160 m/min (525 ft/min) Straighteners (horizontalvertical) with electronic and independent setting for the 2 wires with Joystick Patented feed unit that allows independent advancement for single o double wire (Optional) 2 bending unit Automatic motorized wire change Automatic adjustable wireguide Web Teleassistance Prestraightening Feeding Unit (Optional).

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 6inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CEDS DURADRIVE GMBH

Germany

CEDS servo motors offer you special advantages: Very high acceleration capacity Light and compact design Efficient in terms of size High efficiency even at low speeds High speed stability, torque density and power density High positioning accuracy High speeds can be achieved High dynamics due to the low mass inertia Reinforced winding insulation for high dielectric strength Quiet running Low reactive power requirement Synchronous operation of several drives using a frequency converter Magnetically lockable by the control of the frequency converter Both DC, synchronous and asynchronous motors can be designed as servomotors. Together with a servo amplifier, they then form the servo drive. It can be used to precisely regulate the torque, the speed or the position. For this purpose, the current position of the rotor is always measured with a rotary encoder, e.g. an incremental encoder.

Request for a quoteResults for

Servomotors - Import exportNumber of results

8 ProductsCountries

Company type