- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- semi-automatic wrapping machine

Results for

Semi-automatic wrapping machine - Import export

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO ROLL for wrapping carriages (roll container), with hooking / manual cutting of the film and buttons for ascent/descent of the reel, guide carriages, foot operated mechanical lock, loading ramp for pallet trucks, progressive starting device. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform and hook the stretch film to the base then press the start button. The platform begins to rotate, after 2-3 turns operate the button for coil ascent. After reaching the desired height, stop the lifting of the reel and after 2-3 turns stop the machine or operate the descent of the reel and carry out the winding up to the base of the pallet. At the end of wrapping, press the stop button and cut the film. On request we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic scale integrated STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport.

Request for a quote

FERPLAST SNC

Italy

The inverter allows the progressive adjustment of the rotary table, avoiding the immediate start that could cause possible damage to the products on the pallet. Wrapping machine with rotating table mod. FP ECO/A with photocell to height reading of the pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (Machine CE).

Request for a quote

FERPLAST SNC

Italy

Semi-automatic wrapping machine mod. FP BOX with rotating table, suitable for wrapping boxes and small packages. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The standard table has the turntable completely smooth. You can request the non-slip rubber coating or different locking systems of the pack. Current promotion: The FPBOX wrapping machine for boxes is supplied with a free inverter that allows the adjustment of the rotation speed of the rotary table from 10 to 20 rpm

Request for a quote

FERPLAST SNC

Italy

Wrapping machine semi-automatic with turntable mod. FP BOX - TIRES, suitable to the winding of tires coupled with internal diameters from 300 mm to 500 mm. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The machine is equipped with the compressed air device by drive via lever valve for centering and locking of the wheels, consisting of two jaws which are installed on the expansion of extractable pins. To lock and unlock the tires is sufficient to drive the valve lever. The group expansion is raised by about 150 mm. from the plane table.

Request for a quote

INATECH PACKAGING

Romania

Semi-automatic wrapping machine 2000B The Semi-automatic Wrapping Machine 2000B is used for wrapping pallets, with a rotary table. The car is electrically powered and requires an energy output of 1.25 Kw. The Laminating Machine 2000B is equipped with a motorized carriage with fixed ratios for pre-stretching the film and has a rotation speed of 12 rpm (rotations per minute). The distance between the rotary table and the column allows the wrapping of pallets with a diameter of up to 1650 mm, a height of 2200 mm and a capacity of up to 2000 kg. The advantage of this model is that both the rotary table and the column can be adapted to each individual customer depending on the dimensions of the pallets to be packed.

Request for a quote

INATECH PACKAGING

Romania

Semi-automatic wrapping machine 2000 AW The Semi-automatic Wrapping Machine 2000 AW is used for wrapping pallets, with a rotary table. Being a semi-automatic packaging machine, it requires an operator for its operation. The main feature allows direct access via a pallet truck. The packaging machine is electrically powered with an energy power of 1 Kw. The tension of the film takes place through a mechanical clutch manually adjustable by the operator. The distance between the rotary table and the column allows the wrapping of pallets with a diameter of up to 1650 mm, a height of 2200 mm and a capacity of up to 1200 kg. The advantage of this model is that both the rotary table and the column can be adapted to each individual customer depending on the dimensions of the pallets to be packed. TECHNICAL DATA: Pallet size: recommended 1200 x 1000 mm (L x W); Max pallet height: 2200 mm; Maximum pallet weight: 1200 kg; Pallet stability: good - well-structured pallet, without

Request for a quote

INATECH PACKAGING

Romania

Semi-automatic wrapping machine 2000 AWC The Semi-automatic Pallet Wrapping Machine has the role of making the packaging process more efficient, having a cut-out tray to facilitate access with the slide. In the upper part, the wrapping machine has an electric stabilizer, which favors and stabilizes the products on the pallet. The Easy Wrap 2000 AWC machine is electrically powered and requires a power of 1 KW. The foil tension is achieved by a mechanical clutch, adjustable by the operator. The wrapping machine has a standard platen and can support a maximum weight of 1200 kg. Easy Wrap 2000 AWC comes with a color touch screen, through which you can adjust up to 10 different programs for packing the pallet, as well as setting some parameters: speed of ascent and descent, cycle counter, etc.

Request for a quote

INATECH PACKAGING

Romania

Roto Wrap 1000 AE Wrapping Machine With Rotary Arm The Roto Wrap 1000 AE model in the form of a rotating arm is a semi-automatic wrapping machine that allows the palletizing of heavy or light loads, with unlimited weight. The palletizing machine requires fixing to the floor and can process products with dimensions of 1200 x 1200 x 2200 mm. The number of revolutions can be adjusted with the help of an inverter. The rotating arm does not need fixed safety guards, because the self-braking motor combined with the front bumper instantly stops the rotation at the slightest contact with an obstacle.

Request for a quote

INATECH PACKAGING

Romania

Semi-automatic wrapping machine Easy Wrap 2000 BW The Pallet Wrapping Machine is specially designed for wrapping palletized loads with stretch film. Equipped with motorized pre-stretching and a 7.2" color touch panel, the wrapping machine offers an efficient and easy-to-use packaging solution. With a plate diameter of 1650 mm (standard), the palletizing machine can handle products with dimensions of L 1000 x W 1200 x H 2200 mm and can support a maximum plate weight of 1200 kg. Benefiting from advanced functions, such as adjusting the number of rotations on the lower and upper part of the pallet and managing the gradual start of the table by means of an inverter, this palletizer ensures precise wrapping. With the help of the PLC system and the 7.2" color

Request for a quote

HERMA GMBH

Germany

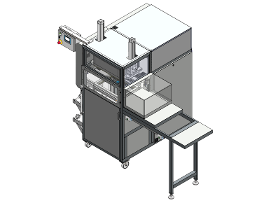

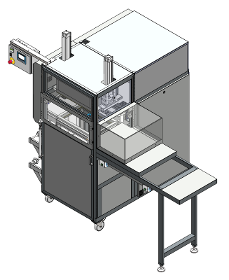

HERMA 211 HC - Feeding demand for personalized medical care The wrap-around labeler 211 HC reliably processes even the smallest batches and products that tend to tip over. Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes. Labels are applied by rotating these products horizontally between two motorized rollers and the pivot peel plate with application roller. The semi-automatic labeling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification. Optionally available with the innovative bad label return for the reliable removal of bad labels. The new 211 HC is therefore tailor-made for processing healthcare products.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO/A ROLL for wrapping carriages (roll container), with manual hooking/cutting of the film and automatic wrapping cycle, limit switches adjustable in height to stop reel holder, adjustable limit switches at the base of the reel holder to start wrapping to the desired height, touch panel display with 3 programs winding, truck driving, foot operated mechanical lock, loading ramp for pallet trucks. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. GEM 350 / GEM 360 / GEM 820 WITH ADJUSTABLE FORMAT AND WITH UPPER AND LOWER DRIVE BELTS The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close boxes high and narrow. Ideal for fixed format boxes close (with constant height and width). Structure of the machine body made of sheet steel bent, bolted and painted. The movement of the cartons is done by two side drive belts driven by a single motor, adjustments for the different formats are made through flywheels. The machine is equipped with 4 wheels with brakes.

Request for a quote

FERPLAST SNC

Italy

The PANDYNO FPPD vertical inserters allow to an operator to fill and seal the packs avoiding the use of preformed bags. The operator must in fact insert the product to be packaged in the magazine tube, on which a few meters of tubular film have been previously loaded. The product goes down into the tubular film up to the support surface. The operator manually closes the sealing bar by applying a slight pressure on the bar. The welding machine in a single operation carries out the welding of the package, the cutting of the film and the welding of the bottom of the next envelope. This operation takes place using an electromagnetic blocking device. By equipping the bagging machine with several loaders, it is possible to increase the productivity of the machine. To avoid waiting times it is also possible to pre-load different magazine tubes so that they can be quickly replaced once the film is finished. The standard model can be placed on a bench and comes with a charger of your choice.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Compared to the traditional shrink wrapper, our Flow Wrapping machine’s main features are high speed and less material waste, the speed has increased by 2-10 times, and you can save labor costs and time, it is suitable for bowl noodles, milk tea, cup products, frozen products, food boxes, cosmetics, clinker bottles, coil incense, and another shrink packaging. The product that has been packed with the film is sent to the automatic shrinking tunnel through the conveyor and run in the shrinking tunnel through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking. The unit adopts a step-less speed regulation device; and cooperates with an automatic dual temperature controller to control the temperature, through the circulation of hot air, the quality of the shrinkage of the film is more stable and beautiful. The unit has high equipment efficiency, compact structure, reliable operation, low noise, and convenient maintenance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

Do you sell or make similar products?

Sign up to europages and have your products listed

HERMA GMBH

Germany

Benefits of the HERMA 414 at a glance: Semi-automatic top labeling designed for a wide variety of formats on both flat and curved surfaces. For label dimensions of up to 100 mm in length and 160 mm in width. The heart of the system is the powerful HERMA 500. Entire machine is controlled by the HERMA 500’s basic drive unit. All necessary parameters can be conveniently set on the integrated operator display. Can be adjusted to different product diameters in no time at all. No control box or PLC required.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

TARHAN AUTOMATION AND MACHINE

Turkey

We produce automatic, semi-automatic and manual assembly machines or assembly lines according to your needs.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Pack Safely and Attractively with your Skin Packaging

Request for a quoteResults for

Semi-automatic wrapping machine - Import exportNumber of results

23 ProductsCountries

Company type