- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- self-propelled

Results for

Self-propelled - Import export

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-60 self-propelled grain loader combines the advantages of a PZM-120M grain thrower and an auger grain loader. The grain loading speed and loader capacity are quickly regulated and range from 10 to 70 tons per hour. Unlike a conventional auger, PZM-60 moves independently and loads itself with grain with the existing scraper feeders. The pick-up width is adjustable and reaches 6 meters. During operation of the PZM-60 grain loader, there is practically no dust. The grain loading height is adjustable and ranges from 2.7 m to 4.27 m. The auger is installed on a special platform that rotates 280 degrees around its axis. This allows you to change the direction of grain loading in 2 seconds. The screw rotation speed is easily adjusted by the installed frequency converter. It is also possible to install a hopper on the PZM-60 screw loader. There is also the possibility of using PZM-60 for moistening grain by installing additional nozzles and a hydraulic pump.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain cleaning complex OBC-70M4 is an ideal solution for cleaning, drying and loading grain any kind of transport. High cleaning quality is ensured by the use of a built-in mesh conveyor, sieves and a powerful adjustable air aspiration system. OBC-70M4 moves independently and cleans and loads grain without the help of other machines and people. This grain cleaner has a capacity of 80 tons per hour for all major crops. At the same time, energy consumption is only 0.25 kW / h for processing 1 ton of grain. The height of storage and loading of grain is up to 10 meters, the flight range of grain is up to 25 meters. Self-propelled grain cleaning complex OBC-70M4 has triple control - automatic, manual and remote. The design of this grain and seed cleaning equipment is as safe and convenient as possible. Anyone can work on OBC-70M4 after instruction, because it is very easy to operate this grain cleaning equipment.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25C self-propelled grain cleaning machine with a cyclone is the latest innovative development. Main advantages of using the OBC-25C: 1. Versatility - used for cleaning any kind of grain and seeds. 2. High quality cleaning and minimal damage to the grain. 3. Move independently and load themselves with grain without help of other machines or people. 4. Can independently load transport up to 3 meters high. 5. Easy and convenient operation and maintenance. 6. Capacity up to 25 tons of grains per hour. OBC-25C with a cyclone is the best self-propelled technique for high-quality and high-performance cleaning of grain, heap, cereals, legumes, oilseeds, corn, sorghum, sunflower, rape from impurities in open areas and in warehouses. You can also choose the model of the OBC-25C grain cleaning machine with an extended elevator, frequency converter, remote control, lighting, bumper, hopper, screw loader. OBC-25C is an ideal machine for cleaning grain.

Request for a quote

NOVELTY STEEL

Turkey

Mobile crushers are mounted on a self-propelled steel platform equipped with wheels, crawlers, or pneumatic pads for movement. The platform incorporates all necessary auxiliary equipment and subsystems for crusher operation. They operate independently on the mine floor. Placed at the working face, the crusher minimizes the need for truck or front-end loader transport, with planned moves occurring between one day and one week. Installation of mobile crushing plants is advantageous under specific conditions; * A clear and undisturbed geological situation, * Straight and long benches for shiftable face conveyor installation, * Long-term mine planning for various conveyors. The benefits of fully-mobile crushers include * Elimination of truck transport * Reduced personnel requirements * Avoidance of high truck maintenance costs * Decreased mine traffic * Overall improvement in mine safety.

Request for a quote

FERPLAST SNC

Italy

Self-propelled battery wrapper, suitable for wrapping with stretch film pallets with a maximum height of mm. 2050, also with an irregular shape. However, the base of the pallet must have a regular shape to allow the feeler wheel to follow its shape. Rotating automatically around the pallet, it wraps with stretch film or net. Equipped with rudder for manual steering with forward-reverse buttons, maintenance-free gel traction batteries, built-in battery charger, three-phase electric motors with inverter, height-adjustable guide wheel, front safety bumper. The FP GLOBO model is equipped with a folding arm with reel holder trolley.Keyboard lock Rotation speed adjustable from 5 to 12 rpm Up/down reel carriage speed from 1.3 to 5.4 m/min Turns at the base/top of the pallet from 1 to 10 Pallet height reading delay Film tension adjustment Film pre-stretch adjustment Reel change comfort cycle CYCLES SELECTABLE FROM

Request for a quote

INATECH PACKAGING

Romania

Robot Palletizing 600 A Palletizing Robot 600 A is a palletizing machine used for wrapping pallets of any shape, weight and size. It is a self-propelled palletizing machine, powered by batteries, designed for wrapping palletized loads of any shape, weight and size using stretched film. The tension of the stretchable film is regulated by a mechanical clutch manually adjustable by the operator. The movement of the pallet wrapping robot takes place automatically thanks to the 2 controls positioned on the guide rudder. The robot is provided at the front with a safety bumper that allows immediate stopping in the event of a collision with an operator or an obstacle.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

In the self-propelled grain cleaner ОВС-25D, cleaning is carried out not on 8, but on 9 sieves. The presence of an additional sieve allows better separation of pure grain and impurities. An additional sieve is installed in the housing of the auger of feed waste and divides them into two parts by size. Due to this, the ОВС-25D grain cleaning machine divides the grain into 4 fractions, and not 3 as ОВС-25 with 8 sieves. ОВС-25D has a capacity of up to 25 tons per hour. ОВС-25D, like other models of ОВС-25 grain cleaning machines we produce, is a self-propelled machine. ОВС-25D independently rides and loads itself with grain without the help of other mechanisms or personnel. Loading is carried out by a chain elevator, which is located in front of the ОВС-25D and picks up grain at a width of 5.3 meters. Grain cleaning in ОВС-25D is carried out both by regulated air flow and sieves, which allows to obtain high quality cleaning.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The grain thrower PZM-120M is an ideal machine for fast loading of any grain into any transport. PZM-120M grain thrower is also used to transfer grain from one place to another. During the transfer process, moisture and light impurities are partially removed from the grain. Transfer of grain is necessary during its long-term storage. PZM-120M grain loader quickly loads grain into grain carriers, automobiles, railway cars, containers, barges, trailers, etc. A full load of a grain truck takes about 15 minutes. The grain thrower PZM-120M is used to work with grain, oilseeds, legumes and industrial crops, while the trauma to the grain is minimal (less than 0.1%). During the operation of the grain thrower, the grain is fed to the conveyor using scraper feeders. The conveyor loads the grain into the trimmer, which throws it through a special guide tube. The trimmer with the pipe easily rotates 257 degrees. Changing the direction and height of grain flight is carried out in less than 3 sec.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Instead of a dust separator and a pneumatic conveyor, a cyclone is installed on a self-moving OBC-25CB grain cleaner, and a hopper instead of scraper feeders. The volume of the hopper of the OBC-25CB grain cleaning machine is about 1 cubic meter. OBC-25CB grain cleaner cyclone collectsdust, straw and light impurities. As a result, personnel can work without respirators and dust does not settle on already cleaned grain, people and equipment. The hopper of the OBC-25CB grain cleaning machine allows the grain truck to unload grain directly into the hopper, and not onto the floor. As a result, grain trauma, energy consumption and wear of the OBC-25CB loading conveyor are reduced. You can also load grain into the OBC-25CB hopper with a screw, noriya, loader, etc. Grain cleaning in OBC-25CB is carried out by adjustable air flow and sieves, which allows to obtain high quality cleaning. You can also purchase an OBC-25CB grain cleaner with a hopper and scraper feeders.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

ОВС-70L is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M4 is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer and sieves. Cleaning grain of any humidity or contamination is carried out using an aspiration system and a mesh conveyor. For better grain cleaning, a self-propelled grain cleaner OBC-70M4L is used. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-bag, hopper, or poured down. Functions performed by the self-propelled grain cleaner ОВС-70L: - cleaning grain heaps of legumes, grains, cereals, corn, sunflower, rapeseed, sorghum, etc .; - loading grain directly into vehicles with a side height of up to 3 m; - loading grain into big bags, bags, bins, loader buckets, etc.; - mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-70M4L is a self-propelled high-performance combination of a grain cleaning machine, a grain thrower and a grain loader, which minimizes human labor when cleaning, shipping and moving grain. OBC-70M4L has the following main advantages: 1. Versatility - the machine cleans,loads, moves and dries all kinds of grain. 2. Used for loading any kind of transport, handling and stacking any kind of grain into piles up to 9 m high. 3. Capacity up to 80 tons of grains per hour. 4. OBC-70M4L is a mobile machine and can be easily transported to another grain warehouse or to another farm. 5. Consume 0.25 kWh of electricity for cleaning, drying, loading and storage of ton of grain. 6. Move independently and load itself with grain without help of other machines or people. 7. Change the direction and height of the grain flight in less than 3 seconds. 8. Easy, safe and convenient operation and maintenance. 9. Minimal grain damage. 10. Good price and quick payback.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Self-propelled grain loader with a large hopper PZM-170B is intended for unloading grain from grain carriers and trailers directly into the hopper of this grain thrower and subsequent loading of granaries to a height of up to 9 meters. Grain loader PZM-170B is also successfully used for loading grain carriers, trailers, wagons, ships, containers and trucks. The size of the hopper is 3.12 meters wide, 1 meter high with a lowered front wall, and a volume of about 4 cubic meters. It is convenient when handling grain in ports, grain warehouses and other premises, or in open areas. Self-propelled grain loader with a large hopper PZM-170B is used in the following sequence: grain loader PZM-170B drives up to the loading point on its own; the hopper is lowered into the working position and rests on the surface of the warehouse; a car, a loader or a tractor with grain drives up to the hopper; the loader throws grain through a special guide pipe to a height of up to 9 m and up to 25 m in lengt

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control panel enclosures for self-propelled machines based on technical documentation provided by the customer, complying with the relevant requirements of PN-EN standards, including mining standards. Enclosures are intended for prefabrication of machine operator control panels, signal-control panel and control boxes, which are assembled on self-propelled machines used in: • mining of metal ores, especially copper ores • mining and processing of mineral resources • tunnel construction • infrastructure construction in road works, earth works and others

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control panels for self-propelled machines based on documentation provided by the customer (electrical and mechanical), complying with the relevant requirements of PN-EN standards, including mining standards. Depending on the application and functionality, we offer the following types of control panels: • machine operator control panel (the most advanced technologically) • signal-control panel • control box The control panel product range is complemented by the electrical wiring harnesses, manufactured based on customer’s documentation. Application • to control self-propelled machines • to protect electrical devices of machines against the effects of short circuits and overloads • to monitor machine operating parameters (working time, fluids pressure and temperature, fuel consumption, air conditioning and others)

Request for a quote

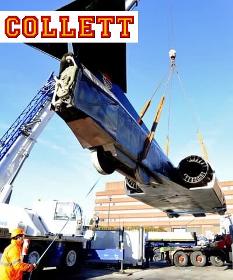

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Our fleet of hydraulic SPMTs provide the ideal solution for manoeuvring abnormal loads in confined spaces and intricately positioning components. The unique 360 degree manoeuvrability our SPMT trailer fleet allows our Team to undertake intricate transport and positioning of abnormal loads and heavy cargo in confined spaces. SPMTs are platform vehicles with hydrostatic driven axles, and regularly feature in our heavy transport and heavy lift operations providing an essential addition when undertaking the movement and positioning of abnormal loads, transformers, industrial cargo, vessels & tanks. The versatility of SPMTs allows them to be coupled in a variety of combinations tailoring to the specific cargo requirements. The unique hydraulic capabilities provide the ability to self load and off-load abnormal loads with a programmable steering option allowing multiple steering geometry patterns.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Under the Construction Plant-Hire Association (CPA) crane rental conditions the client is responsible for supplying all necessary lift plans, Appointed Persons (APs), Slingers, Banksmen and insurance. On behalf of our clients, and with our established crane supplier relationships, we can provide mobile crane hire on a rental basis as an integrated package with our transport operations. Alternatively these crane hire services can be provided in conjunction with our contract lift services as outlines above offering a complete solution. Whether it's manoeuvring machinery within a confined space, loading heavy cargo to an awaiting vessel, relocating transformers or positioning loads, our Team, utilising our jacking & skidding, crane hire and industrial services can provide an integrated solution.

Request for a quote

COLLETT & SONS LTD

United Kingdom

> Click on the "WEBSITE" link for more > Our Permit's Team prepare movement permits for every abnormal, heavy and Out of Gauge transport project and our our diverse fleet of over 60 heavy haulage artic units and 120 specialist trailers and SPMTs ensures that we have the ideal equipment to suit your cargo. Specialist Abnormal Load Logistics Heavy Transport Logistics Heavy Haulage Spmt Transport Abnormal Load Heavy Transport Logistics Our fleet of vehicles includes Low & Semi-Low Loaders, Beam Trailers, Wafer Decks and Multi-Axle Hydraulic Modular Systems up to 3,500Te capacity in 2-,3- or 4-file configuration. Added to this are our SPMT trailers (Self Propelled Modular Transporters), our specialist 550Te Capacity Girder Bridge and our range of Crane Mounted Vehicles & Lorry Loaders including the 205 Tonne/Meter Effer 2055. Coupled with our fleet of Pilot Cars, we can ensure safe and compliant Abnormal Load transportation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

The Platform Truck SFB is a freely manoeuvrable, self-propelled electric vehicle for the in-plant transport of all sorts of heavy loads such as: metal sheets, steel girders, coils, machine parts, cast iron and tools. Due to its modular design, this self-propelled vehicle can be customized to suit various customer-specific requirements. load capacities up to 63t can be used as an all-purpose vehicle indoor and outdoor application cable remote control battery powered electric drive (80V) maintenance-free AC drive technology robust design single-axle, all-wheel and multidirectional steering Options: proportional steering radio remote control cabin or driver's station solid rubber tires for driving over asphalt lighting / LED side lighting loading platform according to customer specification safety devices according to customer specification automatization to a driverless transport system, with partners hydraulic lifting device further options available upon request

Request for a quote

ALPHA LASER GMBH

Germany

The AL-ROCK is a laser hardening system for surface hardening with a self-propelled caterpillar track. The laser can be brought directly to the workpiece. Time-consuming removal of the components to be hardened can often be avoided. The robot arm easily reaches the hard-to-reach places on the workpiece. All common metals can be hardened, e.g. Quenched and tempered steels, cold work steels and cast steel or gray cast iron. The material must have at least 80% pearlite. The degrees of hardness that can be achieved are identical to those of conventional hardening processes. In free 3D movements, the laser beam precisely follows even the most demanding three-dimensional workpiece contours, for example on tracks along closing edges. Pimples, scar structures. Simple points are also not a problem. Only the free access of the laser beam to the surface to be hardened is required. And the AL-ROCK can do even more - on request, the laser robot can also be used for laser welding.

Request for a quotePOUGET

France

USE : Complete Re-Profiling of the rail at high efficiency. (Worn rails, Rail-Corrugation - etc...) ADVANTAGES : This Automatic Unit gives a perfect quality and even results for grinding and re-profiling works on the rails : Running Surface of the rails Gauge-Side of rails and Internal Radius of Head-Rails. This N-320 Modern Machine includes : - 4 Ø 200 mm Grinding Wheels for the Running Surface of the rails (with Slant Setting). (For Tramways Ø 100 mm Grinding Wheels) - 2 Ø 150 mm Grinding Wheels for the Gauge-Side of rails and Internal Radius of Head-Rails. Main Characteristics : - Tri 380 V - 50 Hz Electric Motors with Automatic Controls - Self propelled in two directions = 4/6 Km/H with automatic Speed Variator. - Powered by 100 KVA Diesel Generator on Trolley Platform with Parking Brakes. - Weight of the N.320 = 1800 Kg - Weight of the Generator on the Trolley Platform = 2400 Kg Standard Grinder = 4 x Ø 200 mm + 2 x Ø 150 mm - Ref. N-320 (1 Grinding Unit) Medium Grinder = 8 x

Request for a quote

GL JONES PLAYGROUNDS LTD

United Kingdom

Our newest member to the wheelchair carousel collection with even more opportunities whilst promoting inclusive play! Just like the original D009 AbilityWhirl at 2.4 m with a flush fitting this version has been adapted to allow independence with our self propelled design. Both children and adults with upper body strength will be able to access the wheelchair roundabout using our newly adapted safety gate design and spin the whole roundabout independently. The new safety gates allow for larger wheelchairs and pushchairs to play whilst still keeping safety a high priority by having two enclosed stations with locking safety gates.

Request for a quote

GEOFINAL

Czech Rep.

ANDRIBOT is a universal hydraulic self-propelled drilling and bolting rig, designed primarily for mining environments With its small dimensions and sophisticated technical innovations, ANDRIBOT brings unprecedented possibilities: significantly reduced operating costs in terms of manpower and energy increased safety and modernization of work increased work efficiency and performance performing other above standard work

Request for a quote

PALAZZANI INDUSTRIE S.P.A.

Italy

Self-propelling platform with 980kg hydraulic winch Spider crane with hydraulic winch of 980kg maximum lifting capacity available only on Ragno XTJ 52+ In the crane version, the jib has a special hydraulic installation kit, the hydraulic winch, 51 meter long cable and a support to easily replace the basket. The maximum lift height is 51 meters. Double outreach with variable capacity thanks to telescopic jib: 16,5 m with 250 kg capacity and 12,5 m with 980 kg.

Request for a quote

ASSFALG GMBH

Germany

The weld edge forming/milling machines shear the edge with the help of a cutting wheel, completely self-propelled, noiselessly, and dust-free, leaving a rough bevel. They produce perfect welding edges with the best price-performance ratio. They can chamfer plates and pipes, including large diameters, as well as small parts and pipes with low thickness.

Request for a quote

ÖZEL EQUIPMENTS

Turkey

Maximum Working Height: 18 m Maximum Lateral Outreach: 8.7 m Basket Load Capacity: 250 kg Turret Rotation: 360° Basket Size: 1.4x0.7x1.1 m Basket Rotation: ± 90° Total Weight: 2400 kg Maximum Gradeability: %25 Petrol Engine: Honda GX 390 Electric Motor: 230V - 2.2 kW Transport Length with Basket (A1): 4.75 m Transport Length w/o Basket (A2): 4.05 m Transport Height (B): 1.99 m Transport Width (C): 0.79 m Stabilization Footprint (D1xD2): 3x3 m

Request for a quote

ÖZEL EQUIPMENTS

Turkey

Maximum Working Height: 16 m Maximum Lateral Outreach: 7.3 m Basket Load Capacity: 250 kg Turret Rotation: 360° Basket Size: 1.4x0.7x1.1 m Basket Rotation: ± 90° Total Weight: 2250 kg Maximum Gradeability: %25 Petrol Engine: Honda GX 390 Electric Motor: 230V - 2.2 kW Transport Length with Basket (A1): 4.65 m Transport Length w/o Basket (A2): 3.95 m Transport Height (B): 1.99 m Transport Width (C): 0.79 m Stabilization Footprint (D1xD2): 3x3 m

Request for a quoteResults for

Self-propelled - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Agriculture - Machines & Equipment (9)

- Transport - heavy loads (3)

- Lifts and platform elevators, car (2)

- Adjustment - machine tools (1)

- Basket lifts (1)

- Construction cranes (1)

- Control panels - electric (1)

- Crushing and grinding machinery (1)

- Drilling - machine tools (1)

- Films and sheets, plastic (1)

- Laser - cutting and welding machines (1)

- Metal construction, lightweight (1)

- Packing and packaging - machinery and equipment (1)

- Playground equipment (1)