- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- seal milling machines

Results for

Seal milling machines - Import export

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

FERPLAST SNC

Italy

This special automatic table top/vertical with stand constant heat sealer. Are suitable for sealing polypropylene and paired / laminated bags, paper, barrier materials, etc. The sealing jaws of the type "hot bar" are equipped with resistance and thermoregulator for controlling the temperature from 30 ° C to 200 ° C. The closing of the jaws is through an electromagnet which ensures a high sealing pressure and allows the sealing of thick bags with or without side gussets. Operation The operation provides for the closure of bars and seals the bag following operator control, by electric pedal. This allows the operator to grab the bag with both hands, being able to perform a more precise sealing and parallel to the bag. The vertical model with pedestal can be tilted to 90 degrees, has a special support surface to support the bag during sealing. In this way the operator has both hands free to hold the bag since the sealing is made by pressing the pedal.

Request for a quote

FERPLAST SNC

Italy

MG 300 SEALING MACHINE WITH CLOSING MAGNET Impulse sealers MG 300 series, with 300 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. Maximum weldable thickness 0.15 mm (0.30 tot). Available models: MG 300: bench sealing machine with manual closing of the bars MGM 300: bench sealing machine with motorized bar closing and electric pedal

Request for a quote

FERPLAST SNC

Italy

Machine suitable for the closing of bags with height 200 to 700 mm and max weight. 10 kg. The system with two pairs of heating elements and belts PTFE allows the closing of bags made of polyethylene, polypropylene, cellophane, coated paper, laminated aluminum, etc .This particular welding system is strongly recommended in the presence of bags with high thickness and bellows side. The temperature is controlled by two electronic temperature controllers and the feed speed is adjustable. The distance between the solder and the edge of the bag is 30 mm. The welding head and the conveyor belt are independently adjustable in height through flyers. The machine is equipped with rotary solid ink marker and interchangeable characters (max. 20 characters with height 5 mm.). The system works with inked rollers for easy reading and comes complete with photocell to do the marking in the desired place.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap machine frame from aluminium profile indexing transport system for jars horizontally working conveyor for jar infeed and discharge position control for jars in indexing rotary transport dosing pump from 1.4404 10 l hopper with level control filling nozzles driven by LinMot-e-motor pick and place system for pre-cut foils from magazines driven by LinMot-e-motor 1 spot sealer to fix the foil at the sealing rim of the jars sealing system with conduction sealing head capping station with LinMot-e-motor infeed conveyor for caps electric cabinet with operation panel manual central lubrication system safety doors with aluminium profile frame and windows from makrolon

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

AHP PLASTIK MAKINA

Turkey

Different forms of radius notches can be machined according to various Standards.The notches are at different radius and angles. Micrometer notches at 0.01 sensitivity. Continuous machining is possible with electric motors. 1 TS EN ISO 179-1 A type notch knife is given together with the machine. Notch knives for various Standards(optional); ISO 180 Type A, Type B ISO 179 Type A, Type B, Type C

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ33 compact combines a wide range of applications with excellent price/performance ratio and proven Zimmermann technology. Take advantage of these features for economical machining for a wide variety of parts for Aerospace, Automotive, Tool and Die, as well as many specialty applications. The rigid monolithic structure eliminates special foundations and provides a cost-effective and variable installation in small spaces. Focusing on the power spectrum to machine small and medium size parts, Zimmermann sets new standards and guarantees the user an enormous amount of flexibility and value – in other words, a low business risk due to an attractive cost price, stable machine value and thanks to its flexibility ensured added value.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap • machine frame from aluminium profile • indexing transport system for jars • horizontally working conveyor for jar infeed and discharge • position control for jars in indexing rotary transport • dosing pump from 1.4404 • 10 l hopper with level control • filling nozzles driven by LinMot-e-motor • pick and place system for pre-cut foils from magazines driven by LinMot-e-motor • 1 spot sealer to fix the foil at the sealing rim of the jars • sealing system with conduction sealing head • capping station with LinMot-e-motor • infeed conveyor for caps • electric cabinet with operation panel • manual central lubrication system • safety doors with aluminium profile frame and windows from makrolon

Request for a quote

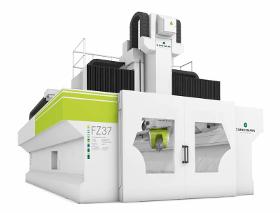

F. ZIMMERMANN GMBH

Germany

Universal metal cutting machine. Designed for highly dynamic machining of different materials. High-speed machining ensures efficient milling results. Advantages: - outstanding price-performance ratio - very broad application spectrum - high-quality universal head for simultaneous machining

Request for a quote

F. ZIMMERMANN GMBH

Germany

With the FZ100 Portal Milling Machine Zimmermann has managed to achieve 6-axis machining using the patented in-house developed M3ABC 3-axis Milling Head. This concept sets new standards in the volume machining of aluminium, composite and model making materials as well as in the High Speed Cutting of steel and cast iron, where conventional 2-axis fork heads with A- and C-axis have long reached their limits in the 5-axis simultaneous machining. Advantages: - Machining four times faster is possible - Perfect quality thanks to the six axes - Highest accuracy possible

Request for a quote

RAPTOREX CNC

Turkey

Product comes with 500 watt Arel AC Monophase Spindle with manual and computerized control. Working area is 340x360x126(mm). The frame is made of aluminum and the device can cut pieces up to 240x360x115 (mm) with precision and without any displacement. All types of wood, plastics (ex: POM.), soft metals (ex: aluminum), hard metals (ex: iron, brass) can be processed. Product is suitable for PCB milling. Axis precision is 0.03mm. Spindle bit holder is ER-16. X and Y axis speed is 2400mm/min and Z axis is 1200mm/min. Linear movement is done by three nema 23 step motor. Step motors are controlled by TB6600 drivers with 24volt PS. Control card is MKS DLC. V2.1. Raptorex Pro requires computer connection to operate and is compatible with both open source and paid software. Product works with GRBL codes. Net weight is 39kg. Our device works silent and does not create vibrations. You may use our device on most regular tables. Product comes ready to operate, you may plug in and start operating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RAPTOREX CNC

Turkey

Product comes with brushless 48V DC spindle with manual control. Working area is 340x240x126(mm). The frame is made of aluminum and the device can cut pieces up to 240x240x65 (mm) with precision and without any displacement. All types of wood, plastics (ex: POM.), soft metals (ex: aluminum) can be processed. Product is suitable for PCB milling. Axis precision is 0.07mm. Spindle bit holder is ER-11. X and Y axis speed is 800mm/min and Z axis is 600mm/min. Linear movement is done by three nema 17 step motor. Step motors are controlled by TB6600 drivers. Control card is MKS DLC. V2.1. Raptorex Mini requires computer connection to operate and is compatible with both open source and paid software. Product works with GRBL codes. Net weight is 23kg. Our device works silent and does not create vibrations. You may use our device on most regular tables. Product comes ready to operate, you may plug in and start operating.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Adopt Simens PLC programmable control system, intelligent interface. 2 . Use the servo motor to ensure the machine's stable performance. 3 . E-stop device.Machine's fully automatic stops working when the machine door is open. 4. Add an electric eye to detect the goods so no goods then not pick carton, avoid empty carton. 5 . With a handwheel and visual dial gauge, easy change over the different carton size packing. 6. Carton store shelf able to store cartons, adjustable frame for different size cartons. 7. High carton feeding rate, carton neatness, and folder ensure the future successful goods loading and carton sealing. 8. The transmission and friction parts are strictly following the standard implementation, with less wear and tear in the later stage, reducing the replacement of accessories. 9. The machine is equipped with an inverter, PLC, voltage regulator, etc. to ensure the stable operation of the machine. 10. Stato Light, alarm when machine malfunction or lack cartons.

Results for

Seal milling machines - Import exportNumber of results

20 ProductsCountries

Company type