- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- screw spindles

Results for

Screw spindles - Import export

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NPACK spindle capping machine is suitable for spindle screw caps, locked caps, and spray caps and so on. The caps can be metal , plastic. Features We adopt the mode of ‘one motor controls one capping wheel’, which can ensure the machine to work stably and keep consistent torque under long term working condition. The clamping belts can be adjusted separately, which allow the machine to be suitable for capping bottles with various heights and shapes. If you choose the optional cap guiding system together with the machine, it will then also fit for pump caps. The convenient construction adjustment system is equipped with precise ruler and counter. The mainframe can be lifted and descended automatically by a motor.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

The fuel systems division specializes in the development and production of serial products. Two main products are produced and sold: fuel pumps which are used in vehicles and flow meters in fuel dispensers which work on the screw spindle principle. Both products meet the high requirements demanded by the automotive and tank facility industries with regard to performance, accuracy and quality. The high overall efficiency in comparison with other pump stages, the low noise emission and the pump's high dirt resistivity as well as the outstanding controllability of a displacement pump make our pumps a reliable and important module in the delivery unit.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures.Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Screw spindle pumps with their silicon carbide spindle housing and highly wear resistant spindles are capable of achieving extremely high pressures. Brinkmann high pressure screw pumps are designed for pumping filtered and lubricating fluids such as coolant oils andwatersoluble coolants. High pressure screw pumps are NOT designed for dry-running. Screw spindle pumps are positive displacement pumps which always require the installation of a pressure relief valve in order to prevent bursting. Volumetric delivery: up to 878 l/min Delivery pressure: up to 200 bar Please contact us for delivery quantity

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Cost-efficient transport between floors The vehicle lift CARRICO is an interesting alternative to the TRAFFICO when lower lifting heights and less frequent use are needed. The CARRICO has been type-tested in accordance with the EU Machinery Directive 2006/42/EC. The conveying speed is limited to 0.15 m/s. Furthermore, this car lift is delivered with automatic sliding doors and cabin equipment designed for the transport of vehicles and passengers. Functions of the components Door type: automatic sliding door (depending on the cabin width - 4- or 6-leaf) Entrances: front only / through Control: Control unit with micro-processor with extensive control functions Drive: Submersible hydraulic unit incl. screw spindle pump Advantages Saves on construction space as no ramp required Especially suitable for narrow shafts Cost-effective way to transport cars Easy to operate, manual hinged doors

Request for a quote

IGUS® GMBH

Germany

Lead-free - According to (RoHS) 2002/95/EG Standards and Certificates drylin® trapezoidal lead screw nut - cylindrical nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WSRM, JSRM, J350SRM and A180SRM drylin® trapezoidal lead screw nut - cylindrical nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WSLM and JSLM drylin® trapezoidal lead screw nut - flanged nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WFRM, JFRM, J350FRM and A180FRM drylin® trapezoidal lead screw nut - flanged nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WFLM and JFLM drylin® Anti-backlash nuts Trapezoidal leadscrew nuts with reduced bearing clearance. Anti-backlash nuts drylin® split lead screw nuts Split lead screw nuts for easy assembly. drylin® split lead screw nut drylin® leadscrew nut - two start two-start lead screws, double stroke in addition to the usual trapezoidal leadscrew nuts. drylin® two-start leadscrew nut drylin® miniature nuts Screw drives ,iniatur lead screw nuts, small sizes. Miniature nuts small sizes drylin® lead screw nuts with spanner flat Ideal transmission of the torque through form fit. drylin® lead screw nuts with spanner flat drylin® disc drylin® disc – eliminate clearance easily at low cost drylin® disc drylin® - Trapezoidal threaded spindle drylin® - Trapezoidal threaded spindle drylin® - trapezoidal lead screws made from aluminum, coated drylin® - Trapezoidal threaded spindle, Aluminium drylin® - Trapezoidal lead screw spindles with pin drylin® - Trapezoidal threaded spindle with pin drylin® - Trapezoidal lead screw spindles reverse Increased flexibility for format adjustments: counter rotating drylin® lead screws. reverse drylin® Zero backlash screw drives Screw drives with steep thread for quick adjustments. Zero backlash screw drives drylin® steep-threaded nuts For quick adjustments as an alternative to pneumatic or toothed belt. Leadscrews drylin® steep thread DST Lubricant-free steep thread DST higher performance in service life and efficiency Steep thread DST drylin® steep-threaded spindles Lubrication-free threaded spindles with high pitches. Steep-threaded spindles drylin® leadscrew nuts made of SHT linear modules Threaded nuts made of SHT linear modules drylin® leadscrew nuts made of SHT linear modules drylin® leadscrew nuts made of SLW linear modules Threaded nuts made of SLW linear modules drylin® leadscrew nuts made of SLW linear modules drylin® leadscrewsstorage Anodized aluminum bearing blocks of iglidur® L250. Design your own linear table. Leadscrewsstorage Floating bearing block for lead screws with ball bearing Useful extension to the drylin® construction kit. Floating bearing block for lead screws with ball bearing drylin® lead screw nut retainer Conveniently use srews to standard lead screw nuts with nut retainers drylin® lead screw nut retainer drylin® spherical trapezoidal lead screw nut To compensate for angular errors in screwed on plates. Spherical trapezoidal lead screw nut drylin® spherical lead screw nut with flange housing spherical trapezoidal lead screw nut, which permits continuous angle adjustments. drylin® leadscre nut with flange housing drylin® spherical lead screw nut with pillow block bearing Spherical lead screw nut with pillow block bearing continuous angle adjustments. drylin® lead screw nut with pillow block bearings drylin® quick-release nut – Fast Forward Fast forward mechanism: A combination of accurate positioning and quick manual adjustment with trapezoidal lead screw nuts. Quick release mechanism drylin® clamping rings drylin® clamping rings - flexible even down to the finest of details, made of coated aluminum. drylin® clamping rings drylin® trapezoidal lead screw nut - cylindrical nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WSRM, JSRM, J350SRM and A180SRM drylin® trapezoidal lead screw nut - cylindrical nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WSLM and JSLM drylin® trapezoidal lead screw nut - flanged nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WFRM, JFRM, J350FRM and A180FRM drylin® trapezoidal lead screw nut - flanged nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WFLM and JFLM drylin® Anti-backlash nuts Trapezoidal leadscrew nuts with reduced bearing clearance. Anti-backlash nuts drylin® split lead screw nuts Split lead screw nuts for easy assembly. drylin® split lead screw nut drylin® leadscrew nut - two start two-start lead screws, double stroke in addition to the usual trapezoidal leadscrew nuts. drylin® two-start leadscrew nut drylin® miniature nuts Screw drives ,iniatur lead screw nuts, small sizes. Miniature nuts small sizes drylin® lead screw nuts with spanner flat Ideal transmission of the torque through form fit. drylin® lead screw nuts with spanner flat drylin® disc drylin® disc – eliminate clearance easily at low cost drylin® disc drylin® - Trapezoidal threaded spindle drylin® - Trapezoidal threaded spindle drylin® - trapezoidal lead screws made from aluminum, coated drylin® - Trapezoidal threaded spindle, Aluminium drylin® - Trapezoidal lead screw spindles with pin drylin® - Trapezoidal threaded spindle with pin drylin® - Trapezoidal lead screw spindles reverse Increased flexibility for format adjustments: counter rotating drylin® lead screws. reverse drylin® Zero backlash screw drives Screw drives with steep thread for quick adjustments. Zero backlash screw drives drylin® steep-threaded nuts For quick adjustments as an alternative to pneumatic or toothed belt. Leadscrews drylin® steep thread DST Lubricant-free steep thread DST higher performance in service life and efficiency Steep thread DST drylin® steep-threaded spindles Lubrication-free threaded spindles with high pitches. Steep-threaded spindles drylin® leadscrew nuts made of SHT linear modules Threaded nuts made of SHT linear modules drylin® leadscrew nuts made of SHT linear modules drylin® leadscrew nuts made of SLW linear modules Threaded nuts made of SLW linear modules drylin® leadscrew nuts made of SLW linear modules drylin® leadscrewsstorage Anodized aluminum bearing blocks of iglidur® L250. Design your own linear table. Leadscrewsstorage Floating bearing block for lead screws with ball bearing Useful extension to the drylin® construction kit. Floating bearing block for lead screws with ball bearing drylin® lead screw nut retainer Conveniently use srews to standard lead screw nuts with nut retainers drylin® lead screw nut retainer drylin® spherical trapezoidal lead screw nut To compensate for angular errors in screwed on plates. Spherical trapezoidal lead screw nut drylin® spherical lead screw nut with flange housing spherical trapezoidal lead screw nut, which permits continuous angle adjustments. drylin® leadscre nut with flange housing drylin® spherical lead screw nut with pillow block bearing Spherical lead screw nut with pillow block bearing continuous angle adjustments. drylin® lead screw nut with pillow block bearings drylin® quick-release nut – Fast Forward Fast forward mechanism: A combination of accurate positioning and quick manual adjustment with trapezoidal lead screw nuts. Quick release mechanism drylin® clamping rings drylin® clamping rings - flexible even down to the finest of details, made of coated aluminum. drylin® clamping rings Lead-free - According to (RoHS) 2002/95/EG Standards and Certificates

Request for a quote

IGUS® GMBH

Germany

Complement of the lubricant-free delivery programs of screw drives small sizes. With spindles made of stainless steel and nuts made of the self-lubricating high-performance plastic iglidur® J. Application areas:small handlings, lab and medical technology, professional model construction, scanner, printer and locking systems Sleeve bearing with flange

Request for a quote

FÖHRENBACH GMBH

Germany

The profiled guide slide PFS is available in 5 series with sizes from 100 mm up to 425 mm width and strokes up to 2000 mm. To protect them against dirt accumulations, the slides are covered with bellow covers. Other covers on request. The slides are available in aluminium (nature anodized), or casted iron GGK-25. Optional steel C-45. The ball thread spindle drives are available in the qualities T5 and T7 with spindle pitches from 5 to 50 mm. PFS (basic equipment) ball screw spindle acc. to standard type allocation screwed up bellows cover coated on both sides integrated inductive limit switches (PNP break contact) incl. plug-connector in the endplate

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

NP-LC automatic spindle capper is almost a universal capper, it is sutiable for capping screw caps, flip flop caps, spray caps, drops caps, metal caps, twist off caps. An automatic spindle capping machine is a device used to cap containers with screw-on caps. The machine works by placing the containers under a series of rotating spindles, which spin the caps onto the bottles or jars. The spindles are adjustable to fit different sizes and shapes of containers, and the speed can be adjusted for different production rates. The machine may also include features such as a cap sorter and feeder, a conveyor system to move the containers through the process, and controls to ensure proper torque and alignment of the caps. Automatic spindle capping machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics, where precise and efficient capping is necessary for product safety and quality.

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation Motor 7,5 KW, S6, 400V / 50 Hz, 2850 R.P.M. For the use of saw blade Ø 550 mm Big cutting range Max cutting height up to 150 mm Max cutting width up to 270 mm 90° cuts Remaining piece from 75 mm Table separation before sawblade retracts powered ball screw spindle material feeder up to 600mm Feed length up to 600mm, Multiple movement of the feeder possible up to 9,9 m

Request for a quote

PRESSTA EISELE GMBH

Germany

High-Performance automatic circular saw for aluminium and non-ferrous heavy metal Fully automatic operation Use of TCT or solid carbide blades ø 250 mm Motor 7,5KW, 400 V, 50 Hz, infinitely adjustable Blade feeder hydropneumatic Material feeder with ball screw spindle and servo motor 2-axis NC control Simatic S7-300 with 7“ touch screen Cutting range: height up to 60 mm, width up to 140 mm Manual safety cover 2x Ø 100 mm swarf extraction connector Blade feeder pneumatic hydraulic controled vertical top to down Manual blade feed adjustment to optimize the feed length Pneumatic clamps horizontal left and right of the blade Diagnosis of errors, trouble shooting Pneumatic clamps vertical left of the blade Mist spray blade lubrication (filling level controlled) 1 l tank Parts slide (Option: conveying belt) Material feeder from 2 – 650 mm with ball screw spindle and servo motor Multiple material feed possible up to 3250 mm cutting length Vertical and horizontal clamps Reducer of...

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For loosening and restoring the usability of rusted threads such as screws, turnbuckles, spindles and stud bolts For removing rust from metal surfaces For removing flash rust and rust stains For cleaning metallic encrustation and oil residues Advantages and benefits Chemical reaction – actively breaks down or dissolves rust layer Environmentally friendly formula – ecologically harmless in use Does not contain petrol or mineral oil – workplace-friendly Low evaporation rate – enhanced effect through longer exposure time

Request for a quote

PRESSTA EISELE GMBH

Germany

High performance automatic circular saw for aluminum and non-ferrous metals Fully automatic operation Infinitely adjustable speed control of the saw blade engine Material and saw feeder movement through servo driven ball screw spindle 2 axis CNC control Siemens S7 with 7” touchscreen Cutting range: up to 205 mm height and up to 400 mm width Rest-piece length as short as 55 mm (depending on profile) Machine can use carbide (TCT) or PKD blades diameter 650 mm (smaller diameter upon request) Automatic kerf widening to reduce scratches Individually controllable clamping pressure Motorized material feed with servo driven ball screw Pneumatic material clamps individually adjustable Positioning of the vertical and horizontal clamps by hand-wheel Cut off lengths of up to 5000 mm are possible by reversing the material feed up to 5 times Floating material feed to reduce material abrasion Feeder length of 1000 mm Simple exchange of saw blade, accessible from the front Saw blade feed is...

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation cutting of aluminium and non-ferrous metal NC Control with touch screen display 5,7” Piece counter showing target/actual number of pieces Piece multiplier when cutting bundles Indication of cycle time Multiple feed device – max feed 3.250mm Table separation before the saw blade retracts so the profile is not touched by the saw blade Electronic material feeder, ball screw spindle and servo motor incl. pneumatic horizontal and vertical clamps Float mounting feeder to balance bend profiles Waste piece from 85mm Reducer of clamping pressure horizontal and vertical Cycle spray mist device with level indicator and automatic stop Cut-off length from 3mm Automatic cut-out when bar is finished Technical Data: Motor up to 18,5kW, S 6 40%, 400 V, 50 Hz, 2850 R.P.M. r.p.m. infinitely adjustable Saw blade speed 3.500 – 5.800 R.P.M Saw blade Ø 400mm Profile width max 200mm height max 120mm

Request for a quote

LUTZ PUMPEN GMBH

Germany

The Lutz-Jesco dry material feeders are precise and reliable devices for volumetric conveying of pourable substances. These devices consist of self-supporting welded constructions made of high-quality stainless steel sheet, which ensures their robustness and durability. Available in various conveying capacities, the dry material feeders offer flexible adaptation to different requirements and areas of application. They are equipped with hollow screws (screw spindles), which ensure even and continuous material transport. Thanks to this technology, they can feed a wide range of bulk materials, including fine dust particles, pellets, flakes and short fibres. Lutz-Jesco dry material feeders are ideal for industrial applications where precise dosing is required, such as in the chemical industry, food processing and many other sectors.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For the long time- or for lifetime- lubrication of fast running roller and plain bearings as well as linear guides, threaded and ball screw spindles, small gears and similar components, exposed to high pressures and higher temperatures Advantages and benefits Good adhesive and good media resistant Good low-temperature behaviour, stress absorbing ability and smooth run at high speeds Good plastic compatibility The low start and running moment, especially at low temperatures, enables a high efficiency The good wear protection increases the life time of the part and makes sure a reliable functionFor best results clean the lubrication point with OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection media before initial filling. Fill the bearings in a way that all the functional surfaces are lubricated sufficiently. Slow moving bearings (DN-value < 50,000) should be filled completely. Fast running bearings (DN-value >400,000) should be filled

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of all kind of high stressed sliding areas, especially at low sliding speeds or oscillating movements, e.g. at threads, joints and bayonet nut connectors made of steel or non ferrous metals Assembling paste with corrosion protection for screws, bolts, spikes, bushings, flanges, spindles and fittings in the whole food stuff industry Separation of high temperature stressed screw joints, even after a long operation time Advantages and benefits Adheres good on metal surfaces, has a good water resistance and corrosion protection Good water resistance Prevents from tribo-corrosion Contains no metal pigments and is free of sulphurous materials Neutral to alloyed steels Formulation according to the FDA guideline 21CFR 178.3570 Registered by the NSF H1 MOSH/MOAH-free For optimal adhesion clean thread and sliding areas from dirt and other lubricants, first mechanically (e.g. with wire brush) and then with OKS 2610/OKS 2611 Universal Cleaner. Apply paste evenly in a sufficient amount

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of highly stressed sliding surfaces, especially at low slip speeds or with oscillating movements, for example with screwed, mating or bayonet connections made of high-alloy steel or non-ferrous metals Surface separation of temperature-stressed threaded connections, for example at combustion engines and turbines Corrosion protection at screws, pins, bolts, flanges, spindles and fits For stainless-steel connections Advantages and benefits Economic product solution for users who previously used a wide variety of pastes Resistant to hot and cold water and also to most acids and lyes Excellent corrosion protection Contains Moₓ-Active for increased performance Metal-free Also available as spray version OKS 2501 NSF H2 registered To achieve optimal adhesion remove soiling as well as other lubricants from the thread and sliding surfaces. Use a brush, spatula or similar to apply sufficient OKS 250

Request for a quote

JUNIE - JUL. NIEDERDRENK GMBH & CO. KG

Germany

3551 knob, rotatable and lockable, ø 30 mm, 2 grip moulds, closing direction right, with pin tumblers, keyed different, metal nickel plated, 7 mm square spindle with grub screw, rose metal black plated, for ø 18 mm borehole, for door thickness 16 - 26 mm, 2 keys

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The VMS automatic machines are designed for the ultimate handling simplicity - both for series cuts and in manual operation. The machine operation takes place using a convenient NC control. Where your operations call for frequently changing single cuts, an optional bar start detection system makes for even simpler material handling through fully automatic length positioning without the need for manual intervention. The generously dimensioned casing complies with the latest safety requirements and can be fully opened for improved access. — Material feed with flat guide and ball screw spindle for high-precision positioning — Large-dimensioned cover hoods meet highest safety standards — Easy to operate in automatic and manual operating mode — Can be combined with roller conveyors — 4 speeds as standard for machining almost any steel quality — Both coolant and micro spray system standard

Request for a quote

DALMINEX GMBH

Germany

Telescopic Spindle Extension T3 with screw bell. A two-piece hot-dip galvanised steel rod accord. to DIN EN 10240 (alternatively in stainless steel), coupling (bottom adapter) made of GJS400-15, galvanised accord. to DIN EN 12329, square cap (top adapter) made of GJS400-15, galvanised accord. to DIN EN 12329 and DIN 50961 (alternatively in stainless steel AISI 304). Suitable for operating key DIN 3223 C or E. Toolles assembly of the spindle extension with a stainless steel clip pin. Connection pins made of stainless steel 1.4301. Transport security of the rod minimum of 150 N. Self-locking in every adjustable position through a PE sealing collar on the steel tube. Torques accord. to GW336. Three-piece PE protection tube system with an additional corrugated protection tube, bonded centring cap and screw bell. Completely dirt-proof and water-repellent.

Request for a quote

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

Most of our rubber bellows are cylindrical , but are also available in cone or rectangular shapes. The typical outline of the bellow ensures that they are easily compressible and stretchable. These are used to cover and protect various machine parts such as pistons, shafts, screws, spindles or pistons from dust, dirt, UV rays, humidity, chemicals or oill sprays and other contaminants. All bellows are moulded and available in different sizes as well as hardness or colors in order to meet any specifications requested by the customer. High resistance to abrasion and external damage doneNo vibration fatigue doneStandard sizes always available More information Our experienced team of engineers is able develop and produce perfectly finished sleeves to suit any specific industrial application. In contact with oil or grease and moderately resistant to weather conditions, we recommend our Nitrile or Chloroprene bellows. However, when used outside (irradiated by the sunlight)

MAXON MOTOR AG

Switzerland

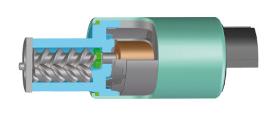

When that extra dose of torque is necessary. Our planetary, spur and special gearheads perfectly compliment our motors. When performance is required at high torque levels and correspondingly low speeds, maxon precision gearheads are in their element. In addition to a wide standard range of spur and planetary gearheads, maxon motor also excels in providing customized solutions, tailored to the customer's requirements. Cutting-edge materials and manufacturing processes are used (e.g. CIM/MIM). The gearheads are adapted to the desired motors on site in the supplying plant, further improving the gearhead performance. maxon spur gearheads Spur gearheads are suitable for low torques. The gearheads consist of one or more stages. One stage represents the pairing of two cogwheels. The first toothed gear (pinion) is mounted directly on the motor shaft. The bearing of the output shaft is usually made of sintered materials. Attractively priced Output torque of up to 2 Nm Reduction ratio of 6:1 to 5752:1 Low noise level High efficiency maxon planetary gearhead Planetary gearheads are suitable for transferring high torque. The larger gearheads are normally equipped with ball bearings at the gearhead output. Torque up to 180 Nm Reduction ratio of 4:1 to 6285:1 High power in a small space maxon Koaxdrive The quiet maxon Koaxdrive gearhead combines worm and planetary gearheads. The signature characteristic of the drive is its unusually quiet running, even under heavy loads. Quiet High reduction ratio in the first stage Combined with maxon EC motors, ideal for medical technology. maxon spindle drive Spindle drives transfer the power generated by the motor into linear feed rate and feed force. The output shaft's bearings can absorb highest axial loads. Compact design due to direct integration of the spindle Comprises planetary gearhead with radial and axial bearings Designed for high forces and linear feed rates Wide range of spindles to suite any applicationWith integrated axial bearing for high axial loads: metric spindles, ball screws and trapezoidal screws are available.

Request for a quote

MAXON MOTOR AG

Switzerland

When that extra dose of torque is necessary. Our planetary, spur and special gearheads perfectly compliment our motors. When performance is required at high torque levels and correspondingly low speeds, maxon precision gearheads are in their element. In addition to a wide standard range of spur and planetary gearheads, maxon motor also excels in providing customized solutions, tailored to the customer's requirements. Cutting-edge materials and manufacturing processes are used (e.g. CIM/MIM). The gearheads are adapted to the desired motors on site in the supplying plant, further improving the gearhead performance. maxon spur gearheads Spur gearheads are suitable for low torques. The gearheads consist of one or more stages. One stage represents the pairing of two cogwheels. The first toothed gear (pinion) is mounted directly on the motor shaft. The bearing of the output shaft is usually made of sintered materials. Attractively priced Output torque of up to 2 Nm Reduction ratio of 6:1 to 5752:1 Low noise level High efficiency maxon planetary gearhead Planetary gearheads are suitable for transferring high torque. The larger gearheads are normally equipped with ball bearings at the gearhead output. Torque up to 180 Nm Reduction ratio of 4:1 to 6285:1 High power in a small space maxon Koaxdrive The quiet maxon Koaxdrive gearhead combines worm and planetary gearheads. The signature characteristic of the drive is its unusually quiet running, even under heavy loads. Quiet High reduction ratio in the first stage Combined with maxon EC motors, ideal for medical technology. maxon spindle drive Spindle drives transfer the power generated by the motor into linear feed rate and feed force. The output shaft's bearings can absorb highest axial loads. Compact design due to direct integration of the spindle Comprises planetary gearhead with radial and axial bearings Designed for high forces and linear feed rates Wide range of spindles to suite any applicationWith integrated axial bearing for high axial loads: metric spindles, ball screws and trapezoidal screws are available.

Request for a quote

LEISTRITZ PUMPEN GMBH

Germany

The reliable generation, transmission and distribution of power can only be ensured with flawless technology in power plants – regardless of whether the focus is on crude oil, coal, natural gas, water or renewable energies. In order to meet the considerable predicted power consumption requirements worldwide, we are ready to provide assistance, with our products and our many years of experience in all of the stated applications with our two, three and four-spindle screw pumps, as a reliable partner. However, our pumps are not just found in power engineering plants such as power plants. When it comes to power transmission, our two and three-spindle ranges have been used successfully for many decades.

Request for a quote

SPARX MACHINE TOOLS

United Kingdom

Between centres: 25" (635 mm) Height of centres: 6 1/2" (165mm) Swing over bed 13" (330mm) Swing over cross slide: 8 1/4" (210mm) Spindle Bore: 1.5" (38mm) 3 & 4 jaw chuck, tool post Coolant Interlocking Chuck Guard Lead Screw cover Foot Brake 12 Spindle Speeds 40 – 2500rpm Main Motor:2.2kW Power:Three Phase Electrics Supply Voltage:415v Approx Dimensions: 1525 x 950 x 1180mm high Approx Weight: 600kg

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification using a portioning device - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport Design: - Simple assembly (plug and play) - low installation costs - Explosion protection model is optional - Good visibility and accessibility - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system - Standard version with 1 working station - Few moving parts resulting in minimized sealing and maintenance costs Drive: - Precise compliance with the torque specification using the slipping clutch or permanent magnet coupling - Screw spindle with adjustable speed Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

FERNSTEUERGERÄTE KURT OELSCH GMBH

Germany

The signals representing angle and length of a telescopic crane are important measuring data. Determination of such measuring data is performed by means of tilt angle and rope length transmitters. The determination of the jib angle is performed by a magnetically damped pendulum system, the swing of which is measured with a redundant high-resolution conductive plastic potentiometer. The output signal is provided in form either of two resistance signals or via the built-in signal converter in form of two current or voltage signals. Linear measurement is performed according to the draw wire measuring principle. One makes use of a multiwire measuring cable, which is wound multilayered on a cable reel provided with a pullback spring. A mechanical spindle lead screw nut ensures, that the rope is rewound and unwound exactly layer-by-layer. The number of drum revolutions, being proportional to the measured length is determined by a redundant potentiometer system voltage or current output.

Request for a quoteResults for

Screw spindles - Import exportNumber of results

40 ProductsCompany type

Category

- Silicones (5)

- Cooling and lubrication pumps (3)

- Machine tools, metal machining - parts and accessories (2)

- Bottling and filling - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)

- Construction machinery (1)

- Dosing - machines and equipment (1)

- Packing and packaging - machinery and equipment (1)

- Planing lathes, automatic (1)

- Power Stations (1)

- Pumps (1)

- Rubber products (1)

- Sawing machine tools (1)

- Slide production (1)