- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- scanners

Results for

Scanners - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

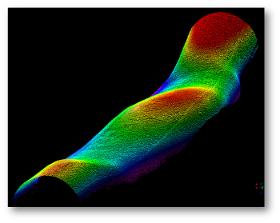

The products get transferred in a continuous-flow process. Products go through the scanner where the mass allocation of each product is determined using X-ray technology. The products are then weighed on the integrated weighing station according to their individual track. The system features a two-stage safety guarding for its radiation source. The CPS-X 400 is specifically designed for weight-accurate slicing of speciality products like Swiss Cheese and those which vary in density, e.g. fat to lean ratio. Optional: Detection of foreign objects: as well as ensuring reliable production, detecting foreign objects also protects units located downstream. This function can be used for detecting, e. g. stainless steel > Ø = 3 mm, glass/ceramic > Ø = 8 mm (product-dependent). Advantages Up to six products in one scan cycle Weight-precise cutting of cheese with holes Density determination of products with significant density differences (fat/lean proportion)

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quote

TODD RESEARCH LTD

United Kingdom

Todd Research have been manufacturing Mailroom X-Ray Screening technology for over 50 years , and we know that resilience in the mailroom is not just about detecting threats . We also know that it’s also about what happens if you actually find a threat. Typically, organisations that have received postal threats in the past say that it’s critical that the accurate information is escalated quickly to enable safe evacuation / quarantine. Todd Research are proud to announce the launch of the integration between the Callmy Emergency Messaging service and the TR-Cabinet range. This means that for the first time a scan can be sent to a dedicated group of first responders of your choice. When the TR – X-ray unit produces an image, the operator can send the scan from the machine using an email function. Callmy transforms the contents of an email into an emergency notification that can be transmitted through the service.

Request for a quote

KEYTRACKER LTD

United Kingdom

Hand held Barcode Scanner for use with Keytracker Software and Barcode Seals.

Request for a quote

COGNEX CORPORATION

Germany

For 1D linear barcodes, higher-density 2D matrix codes, or direct part mark (DPM) codes, the DataMan 150/260 series fixed-mount, image-based barcode readers deliver unprecedented performance, flexibility and ease-of-use. DataMan 150/260 series fixed-mount barcode readers achieve the highest possible read rates thanks to a high-speed, dual core processing engine that runs the latest Cognex algorithms. 1DMax with Hotbars and 2DMax with PowerGrid technology decode damaged or poorly printed 1D and 2D codes, despite code quality, printing method or surface that the codes are marked on, and can even read 2-D codes without visible perimeters or quiet zones. DataMan 150/260 series models offer straight or right-angled configurations to fit into the tightest spaces.

Request for a quote

COGNEX CORPORATION

Germany

The DataMan® 8072 DPM Lite (DL) handheld barcode reader delivers powerful barcode reading performance for tough DPM codes on flat, highly reflective surfaces. It features the latest patented technology and advanced lighting and optics, ideal for automotive, aerospace, and medical device industry applications. DataMan 8072DL handheld barcode readers are optimized with powerful algorithms and technologies to read DPM, as well as 1D and 2D label-based barcodes, in the most demanding industrial environments. 2DMax® with PowerGrid® technology is a breakthrough 2D decoding algorithm, designed to read 2D codes with significant damage.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9012 M has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction.A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9012 A has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction. A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9012 has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction. A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9020 and 9020-2 is a highly efficient 2D laser scanner for mobile mapping applications. The rotation speed of the Z+F PROFILER® 9020 is 267 Hz or 16,020 rpm max.. It measures up to 182 m and has a very high data quality. For data capturing in close range, it is equipped with special optics. Compared to previous models, it has an internal reference plate, a very low power consumption, very fast startup time and over 50% reduced weight and size. A new, very powerful laser technology and further developed algorithms ensures highly accurate measurement results on rails, roads, street signs and other traffic control systems such as traffic lights. Technical highlights: 267 profiles/sec. P9020: 1.094 million points/sec. P9020-2: 2.188 million points/sec. 0.2 mm accuracy 182 m range 360° field of view The Z+F PROFILER® 9020 and 9020-2 can be flexibly integrated into different MMS

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9020C is the world's first mobile 2D laser scanner with integrated cameras. Generate colored point clouds without external cameras The P9020C has four integrated cameras, each with 5 MPx, which cover the entire 360° scanning area as of a distance of 40 cm. The recordings have high color fidelity and a high dynamic range. Significant differences in light conditions are compensated in such a way that the processing of the images afterwards takes short time or is completely eliminated. Shaded or overexposed areas can hardly be seen in the colored 3D representations. Less cabling and connection effort - only one USB 3 cable required The P9020C's built-in cameras allow for quick installation. Only a USB 3 cable is required for the transmission and control of the system components. Fewer cables also mean less susceptibility to errors and, conversely, more security when collecting data.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Based on the high quality laser scanner Z+F IMAGER®, Zoller + Fröhlich GmbH and DMT GmbH & Co. KG have developed an explosion proof 3D laser scanner. The Z+F IMAGER® 5006EX pioneers surveying in underground mining and industries where explosive atmospheres occur. The Z+F IMAGER® 5006EX is the world´s first ATEX approved 3D laser scanner for use in mining and industrial applications under explosive conditions.The Z+F IMAGER® 5006EX is class I and class II approved according to ATEX directive 94 / 9 / EG. The ATEX directive 94 /9 / EG "Equipment and protective systems intended for use in potentially explosive atmospheres" is a European standard. The ATEX approval for this equipment is widely accepted outside the European community as well.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The terrestrial 3D laser scanner Z+F IMAGER® 5016A combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, internal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow. With feature A, which stands for Advanced, the 5016 receives twice as high scan rate of up to 2.187 million pixels/second and more options for leveling the scanner. If the dynamic compensator is deactivated or the tilt is outside the defined range, the tilt is detected by the IMU of the Z+F IMAGER® 5016A.

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

(1)Machine Parameters: -Scanning Model: Electronic Linear Array, electronic convex array -Cine-loop : ≥400 frames -Image Storage : ≥32 frames -Display Depth: ≥250mm -Scanning Angle : Visible and adjustable -Display Mode : B,B+B,B+M,B+M/M,M,4B -Operation Interface : Chinese/English switchable -TGC Adjustment : Near Field, Far Field, Total Gain Independent Adjustment -Focus Control : Focus Number, Focus Distance, Focus Position Adjustment -Image Processing : Image Black/White, Gamma Correction, Edge Enhancement and Histogram -Real-time Depth : 16 levels are adjustable -Zoom : ≥2 times (2)Certification:CE (3)Quality warranty:Main machine:2 year +Probe:1 year (non-human damage within 30 days,free to change new scanner, including free freight cost)

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

(1)Main Parameters: -Screen: 5.6 inches -Display mode: B -Scan: Sector Scan -Probe: 3.5MHz/7MHz optional -Scan Depth:95-185mm -Gain: 30dB-105dB -Image Store: 8GB (SD Card) -Gray Scale:256 -Battery last: 8 hours -Size: 210mmX120mmX40mm -Weight: 1.2kg with battery -Probe Connector: 1 Standard Configuration: -Main Host 1 Unit -3.5MHz Mechanical Sector Selectable 1 Pcs -Internal Battery and charger 1 Set -SD card (2)Certificate:CE (3)Quality warranty:Main machine:2 year +Probe:1 year (non-human damage within 30 days,free to change new scanner,including free freight cost)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

Machine Parameters -Scanning Model:Electronic Linear Array, Electronic Convex Array -Frequency:2.0MHz-7.5MHz -Cine-loop: ≥400 frames -Image Storage:≥64 frame;non-volatile -Image Adjustment:Left/Right, Up/Down, Brightness, Contrast Ratio, Focus Position -Image Processing:Pseudo-color, Image smoothing, Histogram and Gamma Correction -Measurement:General Measurement: Distance, Perimeter, Area and Volume -Obstetrics Measurement: BPD, FL, AC, HC, CRL,GA, LMP, gestational age , EDD. -Report: Automatically reports -Text: Date, Clock, Name, Gender, Age, Doctor, Hospital, Full-screen character editing -External Ports: Video Port, Mouse Port and USB2.0 Port -Battery Capacity:≥2200MAh

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

Machine Parameters: -Scanning Model:Electronic Linear Array, Electronic Convex Array Frequency:2.0MHz-7.5MHz -Cine-loop: ≥400 frames -Image Storage:≥64 frame;non-volatile -Image Adjustment:Left/Right, Up/Down, Brightness, Contrast Ratio, Focus Position Image Processing:Pseudo-color, Image smoothing, Histogram and Gamma Correction Measurement:General Measurement: Distance, Perimeter, Area and Volume Obstetrics Measurement: BPD, FL, AC, HC, CRL,GA, LMP, gestational age , EDD. -Report: Automatically reports -Text: Date, Clock, Name, Gender, Age, Doctor, Hospital, Full-screen character editing -External Ports: Video Port, Mouse Port and USB2.0 Port -Battery Capacity:≥2200MAh

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

Main Parameters: -Display size: 7 inch TFT -Scanning manner: Electronic convex array, electronic linear array -Working frequency: 2.0MHz~10MHz -Display mode: B, B+B, B+M, M, 4B -Scanning range: Convex array 60°~150° -Amplification factor:1.0, 1.2, 1.5,2.0 -Gain control: 8 segments TGC and overall gain can be adjusted respectively -Image processing: 8 γ corrections, frame correlation, point correlation, line correlation, digital filtering, digital edge enhancement and pseudo color processing, etc -Image gray-scale: 256 levels -Scanning line number: 512 lines/frame -Frame rate: 30 frames/second -Digital scanning conversion: 512×512×8 bits -Memory capacity: ≥2GB -Conventional measurements: distance, perimeter, area, volume -Obstetric measurement: horses, cattle, sheep, dogs, cats obstetric measurement -Report function: auto make report -Battery capacity: 3000mAH/7.4V,can work more than 2 hours -Display screen: 7" TFT -Output interface: USB port, video.

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

Main Parameters: -5.6 inch TFT screen -Pretty and very light -Full digital imaging technology, crystal-clear Image -Display screen: 5.6" TFT colr screen -Scanning manner: Electronic convex array, electronic linear array -Working frequency: 2.0MHz~10MHz -Display mode: B, B+B -Scanning range: Convex array 60°~150° -Amplification factor:1.0, 1.2, 1.5,2.0 -Image processing: 8 γ corrections, frame correlation, point correlation, line correlation, digital filtering, digital edge enhancement and pseudo color processing, etc -Conventional measurements: distance, perimeter, area, volume -Obstetric measurement: horses, cattle, sheep, dogs, cats obstetric measurement -Image gray-scale: 256 levels -Scanning line number: 512 lines/frame -Frame rate: 30 frames/second -Digital scanning conversion: 512×512×8 bits -Battery capacity: 3000mAH/7.4V,can work more than 2 hours -Memory capacity: 8GB, can optional to 32GB -Report function: auto make report -Output interface: USB port, video.

Request for a quote

YUTIAN FUTAI INTERNATIONAL TRADE CO., LTD.

China

(1)Main Features: -Scanning Model: Mechanical Sector Scanning -Frequency: 2.5MHz, 3.5MHz, 5.0MHz -Display Depth: ≥190mm -Display Mode: B, B+B, B+M, M -Obstetric Measurement: Distance, Perimeter, Area, Volume, Obstetrics(GA measurement for pig) -Battery Capacity:≥2200mAh -Image Processing:Smoothing, Pseudo-color and Histogram -Image Storage:≥128 frames -Text: Name, Age, Gender, Date, Time, Hospital, Language,Full-screen character editing (2)Package/1 piece: -1 unit scanner is in one Aluminum foil suitcase + outer carton -Outer carton size /1 unit : 47X18X38cm -Gross weight /1 unit:750g (3))Quality warranty: Main machine:2 year +Probe:1 year (non-human damage within 30 days,free to change new scanner, including free freight cost)

Request for a quote

QUELLTECH GMBH

Germany

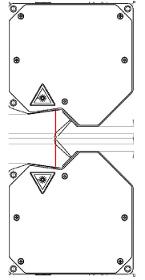

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

Plastic Mold Part (AC Controller) Inspection At this point the manufacturer is looking for scratches and chips and dimension specifications manually. In this respect manual inspection is not a repeatable or trustworthy method to guarantee steady quality of goods. It will be demanding for a human worker to detect this for a long period. QuellTech Solution Plastic Mold Parts are easily measurable materials for QuellTech scanners. Using the QuellTech Q4-120 Laser Line Scanner it is possible to obtain very precise reflection free 3D point clouds. A Software making necessary detections in 3D point clouds can effortlessly check dimensions and find scratches or any other defect which allows the manufacturer to automatically parse outparts that do not pass the tolerance levels.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

QUELLTECH GMBH

Germany

Wear is a damage consisting in gradual removal or deformation of material on solid surfaces, caused by mechanical (e.g. erosion) or chemical (e.g. corrosion) influences. In machine elements, wear may give rise to material failure or loss of functionality. For the application in question, our client has to measure wear on the surface of rollers in cement mills. Up from a certain depth, reactions are required, generated by a warning system to be developed In this project, we used several robust QuellTech Q6 scanners to cover fully the roller width. Due to the high rotational speed of the rollers, we preferred our fastest scanners for this application. We furthermore developed a software solution and implemented a warning system, based on the critical depth of the wears on the surface. By means of this system, the customer can determine the correct time for exchange of the rollers.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

QUELLTECH GMBH

Germany

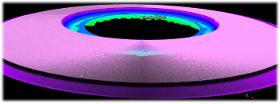

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quoteResults for

Scanners - Import exportNumber of results

203 ProductsCountries

Company type

Category

- 3D scanner (126)

- Bar code scanners (12)

- Sensors (10)

- Light-emitting diode LED (8)

- Medical imaging equipment and instruments (8)

- Machine vision system (7)

- Measurement - Equipment & Instruments (6)

- Security - Services (6)

- Plate glass and mirrors (5)

- Veterinary equipment (5)

- Veterinary products (5)

- Food Industry - Machines & Equipment (2)

- Office machines and equipment (2)

- Surface inspection systems (2)

- Scanners, office (1)

- 3D software (1)

- Bending machine tools (1)

- Cables - accessories (1)

- Handles - doors, wooden (1)

- Infrared tubes (1)