- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sandblasting systems

Results for

Sandblasting systems - Import export

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

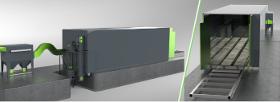

Sandblasting cabin also called Shot Blasting Room; It refers to the closed sandblasting area in which sandblasting is carried out with the labor of one or more operators. Sandblasting rooms: It consists of the Cabin, the Sandblasting System, the Recycling System that allows the used sand to be reused, the Ventilation & Filtering System and the Control Panel. It is mostly preferred for sandblasting a large number of parts that do not require a large and automatic machine. Automotive, Steel Construction, Defense Industry etc. preferred in the sectors. Standard sized sandblasting chambers are shown in the table below, although they are produced by BF BLAST in all sizes according to customer needs.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

Pressure Shot blasting cabinets are designed for small and medium blasting in the cabin by talking in a way. They perform faster sandblasting than sandblasting cabinets and can be used with any type of sand. It is envisaged as an integrated state of pressure boilers and vacuum-blasting cabins. Thanks to the cartridge filter coupled inside the cabin, a clear view is provided during sandblasting and the jet-pulse system filter is automatically cleaned with the air used. Words sandblasting cabinets produced by BF BLAST according to needs; They can be optimized as rotary tables, drums, and double doors. The table below shows the types of vacuum cabinets

Request for a quote

BLASQEM, LDA.

Portugal

The NORMFINISH NP12 blasting booth is an abrasive projection system with water (wet sandblasting system), suitable for the "soft" finish of parts. Equipped with a special pump that allows a continuous supply of water and abrasive to the stripping nozzle. At the outlet of the nozzle, to the water / abrasive mixture, compressed air is added to increase the speed and additional power of the working mixture. The mixture is collected in a funnel, with pump stirring to keep the abrasive in suspension. Dust-free process Degreasing and sandblasting in one process Low impact on surfaces Smoother surfaces, with less adhesion to contaminants. Dimensions of the blasting chamber (width x depth x height): NP12: 1110 x 885 x 870 mm

Request for a quote

PETROGAZ

Turkey

Product Description:Industrial LPG Storage Bullet Tank Volumes:13 m3…to 500 m3 Standards:EN 13445, EN 12542, AD 2000 (MERKBLATTER), ASME, Sec. 8 Div. 1. Steel Plate Quality:P355 NH,NL Design Temperature:EN 13445, EN 12542, AD 2000 (MERKBLATTER), ASME, Sec. 8 Div. 1. Design Pressure::According to The Standard Test Pressure:According to The Standard Loading & Unloading:Upon Customer Request and Standards. Control and Certification:Independed Third Party Weldings:All welded joints are tested according to the manufacturing standard. X-Ray, UT, Penerant, Magnetic Particular Tests are performed. Paint Work:Tanks are sand blasted and coated. Dogan Yıldız offers High Quality Paint Work with Long Life Time by using it’s High Technologic Sandblasting & Painting Booths System.

PETROGAZ

Turkey

Product Description:Bobtail LPG Tank Volumes:10 m3…to 34 m3 Standards:EN 12493 ADR, AD 2000 (MERKBLATTER). Upon Customer Request manufacturing can be done according to ASME or other Standards Steel Plate Quality:P355 NH-NL, P460 NL. According to EN 10028-3 Design Temperature:EN 12493, AD 2000 (MERKBLATTER), ASME, Sec. 8 Div. 1. Design Pressure:According to The Standard Test Pressure:According to The Standard Loading & Unloading:Upon Customer Request and Standards. Control and Certification:Independed Third Party Weldings:All welded joints are tested according to the manufacturing standard. X-Ray, UT, Penerant, Magnetic Particular Tests are performed. Paint Work:Tanks are sand blasted and coated. Dogan Yıldız offers High Quality Paint Work with Long Life Time by using it’s High Technologic Sandblasting & Painting Booths System. LPG Transfer Systems:PTO&Hydraulic, PTO&Shaft, Electrical.

PETROGAZ

Turkey

Product Description:Semi-Trailer AMMONIUM Tank Volumes:30 m3…to 50 m3 Standards:EN 12493 ADR, AD 2000 (MERKBLATTER). Upon Customer Request manufacturing can be done according to ASME or other Standards Steel Plate Quality:P355 NH-NL, P460 NL. According to EN 10028-3 Design Temperature:EN 12493, AD 2000 (MERKBLATTER), ASME, Sec. 8 Div. 1. Design Pressure:According to The Standard Test Pressure:According to The Standard Loading & Unloading:Upon Customer Request and Standards. Control and Certification:Independed Third Party Weldings:All welded joints are tested according to the manufacturing standard. X-Ray, UT, Penerant, Magnetic Particular Tests are performed. Paint Work:Tanks are sand blasted and coated. Dogan Yıldız offers High Quality Paint Work with Long Life Time by using it’s High Technologic Sandblasting & Painting Booths System. AMMONIUM Transfer Systems:Hydraulic, Electrical Type of Axles:Mechanical Suspension, Pneumatic Suspension.

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sandblasting systems - Import exportNumber of results

6 ProductsCountries

Company type