- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- routers

Results for

Routers - Import export

ADS-TEC INDUSTRIAL IT GMBH

Germany

ADS-TEC Industrial IT offers two router/firewall series for network security in industrial environments. These are the IRF1000 and the IRF3000 series. These firewalls are an all-in-one solutions in terms of security. Several functionalities are offered in one product. The firewalls are convincing as a remote maintenance centre, router or edge device, which controlls networked machines and systems without cascading and securing them locally. Thanks to the integrated Docker technology, the IRF series can process data independently, making them the ideal platform for versatile applications in the Industrial Internet of Things. Depending on the model, the networks range from 400 Mbit/s to 8 x 1000 Mbit/s.

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The new concept in copy routers, this single head copy router has the ability to program X, Y, Z and C coordinate with 4 axis servo controlled motors. It is used for the processing of slots for locks, drilling handles, hinges, espagnolette holes, and opening water drain slot on PVC and aluminum profiles, this means no more template GENERAL FEATURES Designed for the day-to-day operations on PVC, aluminum and low alloy materials the four surfaces of profiles at the same time Equipped with servo controlled table mechanism to stop the turning table and machining the profile in any angle among the 0°/90°/180/270° Working capacity X: 300 mm, Y: 120 mm, Z: 115 mm Profile clamping width (Wmax / Wmin): 120 X 30 mm Profile clamping height (Hmax. / Hmin.): 115 X 30 mm Profile clamping length: (Lmax. / L min.): 3000 X 400 mm ER 16 tool collets Equipped with variable speed spindle adjusted from 0 to 12000 rpm with 2.2 kW PLC control system

Request for a quote

VENTION TECH GMBH

Germany

Cat 7 Ethernet Cable 6 FT,VENTION High Speed Cat7 Internet Network Patch Cord RJ45 Connector Professional LAN Cable Compatible for Router Gaming Modem PS4 PS5 Xbox

Request for a quote

PRESSTA EISELE GMBH

Germany

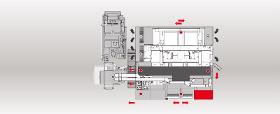

zum Bearbeiten von Aluminium- und Stahlprofilen mit 1 vertikalen Fräsmotor, Antrieb 1,1 kW, 220/240 V, 50/60 Hz Drehzahl 7.000 – 11.000 U/min 2 pneumatische Kopierbolzen, mit Kopierstift 5/8/10 mm pneumatische Werkstückspannung 2 horizontale Spannzylinder 1 pneumatische Sprühdüse Fräsbereich, Länge/Tiefe, 365 x 230 mm Profilhöhe max. 150 mm, Profilbreite bis 300 mm Bedienung über Schalter und 2 Handhebel

Request for a quote

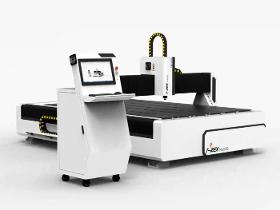

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

PRESSTA EISELE GMBH

Germany

Zum Fräsen von Aluminium und Kunststoffprofilen speziell im Fenster und Türenbau Profiltiefen bis 110 mm, Bearbeitung von 3 Seiten. Profilbreiten bis 300 mm, nur mit vertikalem Fräsmotor (z. B. für Briefkasten) Antrieb mit 3 Fräsmotoren, dadurch sehr stabiler Aufbau. Drehzahl der einzelnen Motoren stufenlos regelbar, 7.000 -11.000 U/min. Kopierfräsen im Verhältnis 1:1 mit allen 3 Frässpindeln, dadurch Einsatz preisgünstiger Serienwerkzeuge. Separate Bedienung der vertikalen und horizontalen Frässpindel über 4 Handhebel.

Request for a quote

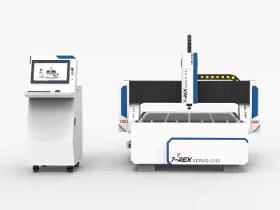

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

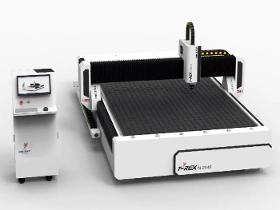

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

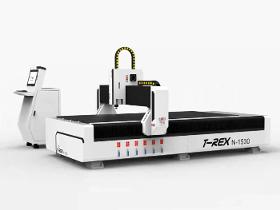

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

The CNC milling machine for all upcoming tasks. Fast, precise and inexpensive. Including CNC control and 2D and 3D CAD/CAM ConstruCAM-3D software. Free lifelong LIVE Support ! CE-compliant commission only with protective housing and the suction socket.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Due to the built-in ball screws, our CNC Router High-Z/T achieves an extremely precise accuracy and an almost no longer measurable backlash of about 0.01mm. In addition, high travel speeds of up to approximately 108mm per second (6500 mm per minute) can be achieved. Installation of protective housing and the suction socket is necessary for CE-compliant commissioning of our CNC machines.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

The particularly short distance of the unique DOUBLE BALL SCREW DRIVE from SAMAG increases the rigidity and thus the machining accuracy immensely. Compared to traditional drive concepts, the TFZ concept is up to 27 times stiffer and more precise. Reduction of vibrations on the drilling and milling unit through DOUBLE BALL SCREW DRIVE and POWER TOWER DESIGN, this is how it works: Second ball screw with additional guide and second pivot bearing on the rear rail (V) Upstream double-guided and particularly strong ball screw drive of the X-axis Minimum distance (l) between tool tip (TCP) and front swivel bearing (A) 1-spindle concept guarantees short, stable tools with excellent accessibility to the workpiece and the machining point Generously sized work spindle to achieve maximum performance parameters Stiff milling spindle with additional, patented support Variable steady rest positioning system to increase drilling accuracy with spacer between spindle and steady rests

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SMART STRETCH TECHNOLOGY – INTELLIGENT USE OF SPACE. SMART STRETCH TECHNOLOGY – means flexibility in widening the work area in optimal harmony with your processing workpiece, while maintaining the same, cost-optimized machine size. Variable spindle distances in the X axis within the MFZ 7 Adaptation of the workspace design to the machining workpiece Lower machine investment costs thanks to workspace flexibility Lower additional production costs due to optimal machine installation space Shorter delivery times thanks to modular machine design Ecological, because only as much “machine” is manufactured as is required for your workpiece Higher productivity by increasing the number of spindles with the same working space per spindle in the same machine size Definition of the machine by the workpiece and not by the spindle distance

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

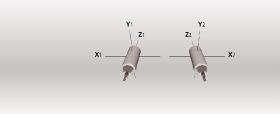

2-SPINDLER WITH TWO INDEPENDENTLY CORRECTABLE 3D UNITS (X, Y, Z) FOR HIGHEST PRECISION WITH CRITICAL TOLERANCES. COMPARABLE TO TWO 1-SPINDLE MACHINING CENTERS STEREO 3D SETUP – CONSTRUCTIVE DECOUPLING OF THE 2-SPINDLE SYSTEMS. 2-spindle with two independently correctable 3D units (X, Y, Z) Highest precision for critical tolerances Comparable to two 1-spindle machining centers Easy tool setup and lower tool costs New range of workpieces - finish processing of complex components Minimal setup time for new workpieces

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Machining time on 3-spindle solution 97s Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Processing time less than 80s per workpiece possible Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

3 or 4 spindle machining Complete processing on MFZ Processing time less than 55s per workpiece

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quoteResults for

Routers - Import exportNumber of results

52 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (10)

- Milling - woodworking machinery (7)

- Machine tools, cutting - parts and accessories (5)

- Milling - machine tools (4)

- Cables - accessories (2)

- Control boxes - electric (2)

- Cutting, plastics - machinery (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Milling - steels and metals (2)

- Cutting - steels and metals (1)

- Engraving, industrial - steels and metals (1)

- Machine tools, metal machining - parts and accessories (1)

- Metal engraving - machine tools (1)

- Networks - installation and maintenance (1)

- Telecommunication by internet (1)

- Woodworking - machinery and equipment (1)