- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rolling machines

Results for

Rolling machines - Import export

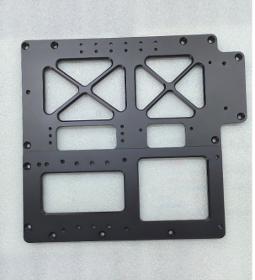

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

COPIER MACHINERY

Netherlands

Pipe beveling and cutting is way faster end efficient with electrically height-adjustable roller benches. Our TRB roller benches are highly stable and have two control options manual and automatic for very heavy pipes or automated pipe operations. TRB roller benches are easy to adjust for different diameter and reduces the production time. Also, automatic TRB can be integrated into a fully automated production line. Copier Machinery also designs roller benches with measurement and pipe push up system, especially for pipe cutting. Suitable for pipe diameters up to outside diameter 56”, with a length option up to 12 meters. All TRB roller benches are designed and manufactured by Copier Machinery, and they are scalable upon special requests and requirements.

Request for a quote

COPIER MACHINERY

Netherlands

Copier Machinery manufactures roller benches up to 12-meter length, specifically for pipe roll grooving applications. Steel ball transfer units are placed on the bench allow a pipe to move and turn to support the roll grooving application perfectly. Grooving roller benches are electrically height-adjustable and scalable upon special requirements.

Request for a quote

FÖHRENBACH GMBH

Germany

The rotary table combination RT3A100 consists of two directly driven rotary tables of the RT3A100 series. The B-axis has a swivelling range from approx. -10° to +110°; the C-axis can be rotated infinitely. The unit is driven by two integrated 3-phase synchronous motors. The drive guarantees highest dynamics and precision. An innovative clamping unit integrated in the housing guarantees high holding forces when the drives are switched off without position changes on the axes. By means of compressed are impact, the holding torque can be increased from 15Nm to 20Nm for special applications. The complete system is supplied as ready-to-connect unit.

Request for a quote

GSW SCHWABE AG

Germany

GSW Roll Feeds Precise and fast positioning with lasting performance. Built with the attributes of parallel adjustment of the top roll, highprecision roll guiding and mechanical stroke limitation for fastest cycles. In combination with most modern motion control systems our Roll Feeds feature a highly reliable production support with dynamic feeding performance of max 30 m/s² acceleration. For smaller crosssections we offer the HSseries Roll Feed model This dynamic and costeffective solution makes the upgrade from gripper feeds to the much more flexible roll feed technology affordable. from coil up to 2000 mm material width and up to 8 mm thickness max crosssection approx. 2000 x 5 mm Vmax approx. 80 200 m/min max cycles with pilot release approx. 100 220 SPM from plate or bar up to 20 mm material thickness

Request for a quote

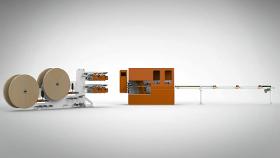

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

60m/min Core Rolling Machine is a machine that plays an important role in industrial production and is used to roll paper and similar materials. This machine has a technology that increases productivity and speed, especially in large-scale production. The 60m/min core maker Machine, which turns paper main bobbins into tubes at high speed and without interruption, significantly increases the speed and efficiency of the tube production process. 60M/min Core Machine is a machine used for making cores in the production of products such as toilet paper and kitchen towels in the paper converting industry. This machine, which is especially used in large-scale paper production facilities, turns the paper into cores and facilitates storage and transport processes. This machine attracts attention with its high speed and uninterrupted production capacity. High Speed and Efficiency: Designed for fast production processes, which increases production efficiency.

Request for a quote

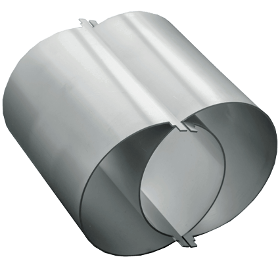

SINOP SMP

Czech Rep.

Individual and serial production Rolling on the plate rolling machine with four actuated rolls Roll diameter 70 mm CNC control Feasibility to roll intricate elliptical shapes Maximal work length 1040 mm, maximal sheet thickness 2 mm

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

We offer our customers the leasing of our test bays for testing your machines and systems.The above-mentioned machines can also be coupled in sets of three so that even higher outputs are possible. At LDW we also have several DC machines with other speed ranges and lower outputs. We also have three-phase load machines with speed ranges from 750 to 3,000 1/min at an output range of 1,400 to 3,000 kW. Our largest measurement shaft has a torque of 5,000 Nm (accuracy class <1%). We usually verify the torque via a DC-machine. We have several DC machines with speed ranges of 100 to 6000 1/min in the test bay (depending on requirements) at an output range from 100 to 1,500 kWThe maximum torque of our largest measuring shaft is 5,000 Nm (accuracy class <1%), we usually verify the torque via a DC-machine. Depending on the specific needs we have several DC-machines with speed ranges from 100 to 6,000 rpm and outputs from 100 to 1,500 kW.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Machines are only as reliably available as their spare and wear parts. We therefore offer a comprehensive range of all important services. Thanks to our extensive archive, we are in a position to offer spare parts and services even for older machines from LDW, AEG and Garbe-Lahmeyer. We only need the serial number of the old motor or generator to provide or manufacture the corresponding spare parts. We are happy to assist with any question you have concerning our spare parts services, tender preparation or on-time procurement and delivery. The quality specifications we have for new parts of course also apply to our spare partsDespite the high quality of our products, the service life of some components is essentially determined by operating and environmental conditions. To avoid costly downtimes it is essential to implement preventative measures. Stocking spare parts is one example of such a sensible measure.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

The repair works are located at our site in Bremen. Through the utilisation of all the resources of our manufacturing operations our customers enjoy all the benefits of repairs, maintenance and reconditioning in accordance with the DIN IEC60034-23 standard. For work on explosion-proof machines we can provide all the certificates required for order fulfilment in full compliance with legal provisions. LDW has a certified expert and the legally binding permits ATEX, PTB KTE etc. required for a professional execution. All AEG documents from around 100 years of electrical engineering are available in their entirety within our company. This enables us to carry out repairs, supply spare parts or complete machines that are electrically and mechanically interchangeable. As part of this process we upgrade these procedures in step with the latest technological developments. The energy balance is thereby significantly improved on a regular basis.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

It is increasingly important to make provisions and to keep one’s own machines in good condition. This reduces downtimes and prevents a decline in production. Our seamless diagnostics helps to ensure that machines run fault-free and enables advance planning of maintenance or repair work. The experts from LDW bring their equipment to the customer to inspect the machine on site. From partial discharge measurement through to vibration measurement – we clearly identify what technical state a machine is in. This allows downtimes to be planned ahead and ensures the efficient repair of the respective component.Diagnostics at our works in Bremen is even more effective, because we can directly consult an expert from the mechanical construction, electrical calculation or the R&D department for an assessment if necessary. The customers are provided with a comprehensive protocol after the measurements have been carried out. We then recommend the next steps for a repair or continued operation.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you idler pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The carrying frame prevents belt misalignment and guarantees protection of the belt edges. As the carrying frames only function efficiently when the drum casing is clean, they are equipped and delivered with dirt repellent 60° shore soft rubber. Our carrying frames can be used with both normal and reversing conveyor belts. Mode of operation When the conveyor belt is running straight, the axle through the roller casing forms an angle of 90° to the direction of movement of the belt. When the belt drifts, the roller casing moves, due to the dead weight of the belt, so that a forward motion occurs which brings the belt back to its normal position. The roller casing returns to its normal position as soon as the corrective procedure is completed. The mechanics of the movement are rendered possible due to a complex ball joint in the centre of the roller as well as the position of the axle in relation to the conveyor belt being less than 90°.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

For the special requirements of your belt conveyor system, we manufacture for you drive pulleys, carrying idlers, throbbing drums, lift pulleys with or without internally located cone. With diameters up to max. 1,000 mm and lengths up to max. 4,500 mm, these are suitable for all types of belt conveyor system. All pulleys are turned cylindrically or spherically. The axle connections can be delivered in alternative designs with internal bearings, welded, with wedged connections or with clamping set shaft connections. Special designs such as stainless steel and/or friction linings (ceramic, rubber) and accessories (pedestal bearings) can be delivered upon request.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Carrying rollers made of steel and HDPE Carrying rollers suitable in both heavy and light application conditions bulk goods and unit load rollers also available for delivery with cogs and conical rollers delivery of small quantities possible

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WINFA, S.R.O.

Slovakia

3 rolls; 400 mm roll diameter; 2 m long rolls

Request for a quote

YCSMAKINE

Turkey

YCS MAKINE is manufacturing shutter Door roll forming machines using high technology in its facility in Turkey since 2004. We bring together the Turkish engineering discipline with our knowledge and experience of more than 18 years in the metal door profile forming machines and related components, development, and production. We design and produce our Roller shutter roll forming machines based on their efficiency, reliability, life-long-running tooling, and craftsmanship. We are exporting 80% of our machines abroad and our profile forming machines running in more than 30 countries. Know-How and engineering capability for different Countries and customers customized demands. Certificates: CE /ISO 14401:2015/ISO 1002:2018/ISO 9001:2015

Request for a quote

YCSMAKINE

Turkey

YCS MACHINE (YUCESAN) is manufacturing shutter door profile Cold roll forming machines using high technology in its facility in Turkey since 2004. We bring together the Turkish engineering discipline with our knowledge and experience of more than 18 years in the metal door profile forming machines and other related components, development, and production. We design and produce our profile-forming machines based on their efficiency, reliability, life-long-running tooling, and craftsmanship. We are exporting 80% of our machines abroad and our profile forming machines running in more than 30 countries. More about us; More than 18 years of Experience in Metal Shutter profile cold roll forming machines production. Precise tooling and production using Japanese and German, Korean CNC machines. nous sommes fabricant de Profilage, Profileuse pour volet roulant Profileuse, de profilage, Ligne de poinçonnage profilage

Request for a quote

YÜCESAN MACHINE

Turkey

The machine consists of three parts. These; uncoiler, machine, conveyor. Conveyor and uncoiler are included in the machine. Uncoiler 1000 kg. There are two types of uncoilers, with motor and without motor. The machine is produced using 4140 steel molds with 50x56 rocwell hardness. The machine consists of guillotine cutting. Automation system language options; Turkish, English and French. An optional language can be added. The number of stations is 12. However, the number of stations can be changed according to demand. It produces 20-25 meters per minute.

Request for a quote

IUSYS

Portugal

IUSYS PR210 - Mattress Wrapping, Folding and Rolling Pressure plate size: 2070mm*2400mm Max Pressure: 100T Mattress Max. Size: 2300*2100*400mm Efficiency: 35s/pcs Diameter: Adjustable (22-50cm) Total Power: 46kw Foam density: ≥25kgs/m³,≤45kgs/m³ Voltage:As your requirement Total weigh totalt:20000KG Overall Dimension: 15000*3400*3000mm

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Our metal work unit is equipped with all the equipment required to carry out the majority of operations related to the production and shaping of metal objects: mortising machine, press, drilling machines, rolling machines, semi-automatic welding stations and TIG/Plasma/Oxycutting workstations. Our vast range of metal work equipment and the adaptability of the workshop’s covered areas are ideal for performing almost every type of shaping.

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our four-cylinder rolling machines offer a maximum width of 1900 mm, and pipe twisting up to a diameter of 220mm at max. 6mm gage. In smaller versions 1000mm, for diameter min. 125mm

Request for a quote

COPIER MACHINERY

Netherlands

The Groove Master works with an electro-mechanical driven system operated by an IPC. The grooving parameters and batch specifications (tube diameter, wall thickness, length, material, and the number of pipes in one batch) can be entered manually and saved for later or can be chosen among the available recipes within the program.

Request for a quote

ID GROUP

France

ergonomic slabs which maintain worker comfort and which at the same time resist the passage of rolling machines and heavy loads interlocking slabs on 4 sides for flexible arrangement quick installation antifatigue function thanks to its lower surface consisting of «FlexPoints» supports up to 45 tonnes / m² easily separable and reconnectable panels to obtain a new configuration yellow safety angles and ramps available to secure and facilitate access to the slabs by users and rolling machines very good resistance to chemicals

Request for a quote

MICRON AMERICA

Turkey

Continental Area Flat Rate Shipping fee $49.99 This machine can accommodate every die we manufacture. Simple straightforward design allows even a novice to professionally set grommets, rivets and snaps and Portable design allows you to take it to a job site. Package Deal Includes √ M 3 Grommet Machine √ #8 Rolled Rim Grommet dies with Hole Piercing dies and Teflon board √ 1 bag of #8 Rolled Rim Grommets and Washer (144 pcs of each) The Micron M 3 is our favorite manual fastener press. The versatility of this amazing fasteners press is simply unmatched as far as manual fastener presses are concerned. 1. Versatile The Micron M 3 is specifically designed to attach curtain grommets size #12 # 15 and #18. The M 3 does a great job of installing curtain grommets. This is rare for a manual grommet press the size of the M 3. If you are looking for a portable manual grommet press to attach curtain grommets, this is it.

Request for a quote

AKOMEX GROUP

Poland

LABELS PRODUCED ON PAPER OR FOIL LABELS PRODUCED ON A SILICONE OR FOIL BASE FLEXO TECHNOLOGY LINES FOR PRINTING AND ROLLING ROLLING MACHINES EQUIPPED WITH ELECTRONIC SYSTEMS FOR 100% IN-LINE PRINT INSPECTION SYSTEM

Request for a quoteResults for

Rolling machines - Import exportNumber of results

73 ProductsCountries

Company type

Category

- Rolling machines (19)

- Toilet paper (6)

- Bakery and confectionery industry - machinery and equipment (4)

- Lead sheets and bands (3)

- Packing and packaging - machinery and equipment (3)

- Bending machine tools (2)

- Copper and copper alloys (2)

- Custom packaging (2)

- Profiling shapers (2)

- Metallurgy - machinery and installations (1)

- Adjustment - machine tools (1)

- Bending - steels and metals (1)

- Cigarette paper (1)

- Confectionery - machinery and equipment (1)

- Copper sheets and bands (1)

- Cutting, plastics - machinery (1)

- Folders, paper (1)

- Folding machine tools (1)

- Food industry packaging machinery (1)

- Foods, precooked and gourmet (1)