- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roller machine

Results for

Roller machine - Import export

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO's Extended Life Specification Machined Type Needle Roller Bearings are treated with a newly developed special heat treatment that enhances the bearing's surface hardness and toughness, and suppresses the generation and growth of damage on the surface. Significant life extension can be achieved under high load or under the condition of lubrication contaminated with foreign substances. In a life comparison test, IKO's special heat treated Extended Life Series products lasted 5 times longer than standard heattreated products.

Request for a quote

GURTEC GMBH

Germany

Excellent roundness and balance reduces vibration and ensures quiet operation and extended roller life Dimensions: Roller diameter 127-194 mm (5 to 7-5/8”) Shaft diameter up to 60 mm (2-3/8”) Bearing 6305, 6306, 6307, 6308, 6309, 6310

Request for a quote

GSW SCHWABE AG

Germany

High feeding accuracy, quick cycles and simple operation Servo feeding in compact design with maintenancefree AC servo motor Fits just about any press +/ 0,025 mm feeding accuracy through incremental servo encoder Lightweight rollers with special hard chrome layer Mechanical pilot release Sturdy steel plate bolton design Height adjustment via threaded spindle Catenary rolls and edge guides at machine entrance Stock guides at exit Highperformance control with good functionality; with remote control for setup on 3,5 m cablel 24 V DC proximity switch adjustable piloting lever to be mounted to press pneumatic pilot release

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used in the sieving and classification of the grains milled by the Roller Mill Machine

Request for a quote

KONYA MILL

Turkey

This is the main part of the mill machinery factory which grinds the wheat. We have two types of Rollers: Manual and Automatic system with PLC. The grinding unit also includes the other machines as semolina grinder. For more information, pictures and videos you can both contact by mobile or whatsaap or email: export.milltek@gmail.com Also you can refer to our website by clicking the following link: http://www.millteknoloji.com/urunler/47-ogutme-unitesi/

Request for a quote

METAL IN LTD

Bulgaria

Metal In Ltd have two punching machines – TRUMPH and Raskin and two CNC bending machines TRUMPH. This allow us to produce punching details with maximum sizes 1250x2500 mm and maximum thickness 4 mm. Machines are with maximum length 3000 mm and power 120 tones. We also have eccentric presss machines with maximum power of kick 160 tones and hydraulic presses with maximum power 100 tones. We have our own production of punching and bending instruments. The company have three roller bending machines for sheet iron, profiles and tubes. Except upper mentioned operations we also make MIG-MAG and WIG welding, cleaning and powder coating.

Request for a quote

FEMIA INDUSTRIE

France

Separates the free beans from the mechanically harvested green bean clusters. Machine primarily comprised of a drum fitted with hooks of special shape. Mobile machine mounted on rollers so that the position of the drum can be adjusted in relation to the fall of products above the drum.

Request for a quote

PARSMEGA MAKINA

Turkey

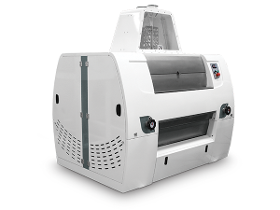

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided as a curtain between the roll rolls.

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Machined Type Needle Roller Bearings are bearings with a low cross sectional height and large load ratings. The outer ring has stable, high rigidity and can be used even for light alloy housings. These bearings are available in metric series and inch series, both of which include a caged type and full complement type. They are suitable for a wide range of conditions including heavy load with either highspeed or lowspeed rotation. In addition, bearings are available with or without an inner ring. The type without an inner ring uses a shaft as the raceway surface, making the design compact.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

Our CLube technology maintains the lubrication performance for an extended period of time, reducing lubrication schedules and the time it takes to manage them.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

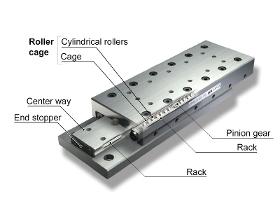

The AntiCreep Cage Crossed Roller Way Unit prevents cage creep by using a rack and pinion mechanism in the crossed roller way that is mounted to a groundfinished rigid table and bed. The builtin rack and pinion mechanism is the perfect solution for cage creep issues. It provides reliable operation in various situations where a crossed roller way would be difficult to use, including applications on a vertical axis. No correction for cage creep is necessary, even under high velocity or long term operation. Interchangeable Mounting Dimensions Since the rack is placed inside the way, it maintains the same outside dimensions and offers complete mounting compatibility with the conventional crossed roller way unit; making it easy to replace the conventional type crossed roller way units in machines and equipment, as well as using it in new designs. UltraHigh Precision and Smooth Motion A combination of a precisely finished raceway surface and a nonrecirculating type linear motion

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Thrust Bearings consist of precisely machined cages and rollers. They have high rigidity and high load capacity and can be used in small spaces. Thrust Needle Roller Bearings use needle rollers, while Thrust Roller Bearings use cylindrical rollers. Various types of raceway rings are available, and can be selected according to the operating conditions. When the bearing mounting surface of a machine is heattreated and finished by grinding, Thrust Bearings can be used without raceway rings, making the machine more compact. They are best suited for applications where high accuracy is required at high speeds and under fluctuating heavy loads, such as the drive mechanisms for automobiles, machine tools, and highpressure pumps.

Request for a quote

NIPPON THOMPSON EUROPE B.V. (IKO)

Netherlands

IKO Needle Roller Cages for General Usage are bearings that provide excellent rotational performance. Their specially shaped cages, with high rigidity and accuracy, precisely guide the needle rollers. Since needle rollers with extremely small dimensional variations in diameter are incorporated and retained in this needle roller cage, they utilize the machining accuracy of the way and are useful in small spaces when combined with shafts and housing bores that are heat treated and accurately ground as raceway surfaces. In addition, since they are lightweight and have high rigidity as well as a large lubricant holding capacity, they can withstand severe operating conditions such as high speed rotation and shock loads, and they are used in a wide range of applications.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit rollers are the result of continuous innovation aimed at improving this product segment. The high quality of our tools provides numerous advantages, especially for general grinding tasks like cleaning and finishing. Our rollers ensure consistently high-quality results on uneven surfaces throughout their lifetime. With a broad range of applications, they are ideal for removing welding marks, scratches, oxidation residues, and large-scale surface pretreatment. New to Tyrolit are spiral rollers with a patented shape that facilitates easy, comfortable work while preventing typical roller marks. Our rollers for floorstand grinders are perfect for finishing, polishing, and cleaning uneven or curved surfaces made of steel, stainless steel, and nonferrous metals. Available in various grit sizes, they cater to different needs: 40-60 for high stock removal, 80-120 for medium grinding, and 150-320 for a perfect surface finish.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

SAMSYS GMBH

Germany

ar feeder for special profiles wanted ? To extend the MULTI 3000 to the bar feeder for special profiles, the Uni-erector can be mounted optionally. It enables the erection of rectangular profiles and special profiles for further transport to connected machine tools. Thus a smooth reloading process is possible. By simply setting a parameter, the erector can be selected or deselected. This enables a quick changeover from round material to a special profile. By deactivating it, the bar loader can load round or hexagonal material as normal. While with activated parameter the bar feeder will load the special or rectangular profile while the reloader is erecting. The use of square material is also optionally possible. The erector consists of two opposite rollers. To erect the material, these rollers move together during reloading. When the bar is threaded into the machine tool, the rollers open again. The distance between the rollers can be easily adjusted.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Soft turn of the bundles Low maintenance Optimal access Very quiet operation Intrinsically safe machine, protection door-less concept Bypass without bundle turning, manually Upstream and downstream interlocks with complete plug connection In conveying direction left or either right Power cable, length 3m OPTIONAL: Bypass without bundle turning, automatically OPTIONAL: One pop-out roller on entry side OPTIONAL: Machine movable Table height steplessly adjustable Many specific options available, easily configurable

Request for a quote

NORELEM FRANCE

France

These precision slideways with roller bearings are used in machine and fixture construction, metrology, optical instruments and precision mechanics. The scale division on the micrometer dial is 0.02 mm. The stated permissible load values (F) are designed for a service life of 1 million travel cycles. The torque values apply only to centred slides. An additional centring hole is located at holes D2 and D3 on the top of the slide. Other connecting elements can be precisely mounted on the slide in combination with our centring rings 20240. F = permissible loading for dynamic and static loads. TI E/E1 = number of fastening holes E/E1/M inside. TA E/E1 = number of fastening holes E/E1/M outside. TI E4 = number of fastening holes E4/D1 inside. TA E2 = number of fastening holes E2/D1 outside.

Request for a quote

KULLEN-KOTI GMBH

Germany

Our brushing machine type BM 1138 has been constructed previously for heavy-duty conveyor belt cleaning in coal mines and foundries. Today we supply it for almost all kinds of industry where conveyor belts have to be cleaned. BM1138-characteristics The particular criteria are: - rugged machine core in welded construction. - high cleaning performance. - minimum belt wear. - small assembly dimensions. - easy retrofitting. - simple mounting to all carrier systems. - integrated vertical adjustment of roller brush. - exchange of the brush coils without removing the roller brush. The brushing machine can be installed at the converyors according position 1-8.

Request for a quote

BF BLAST MACHINERY INDUSTRY AND TRADE

Turkey

It is a type of sandblasting machine used mostly for the purpose of sandblasting sheet metal, profile, and steel constructions in the manufacturing sector. The conveyor is manufactured as a roll or wire band depending on the need. Tunnel-type sandblasting machines are primarily preferred for preparation before painting in integrated facilities.

Request for a quote

AUROMAK MAKINA

Turkey

Our roller part washing machine is suitable for the use of solvents and similar chemicals and is manufactured using a tex certified expuruf products. While removing the dirt with pressurized liquid spray, it provides a cleaner and faster cleaning by means of brushes.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

MULTISPINDLE DEEP DRILLING MACHINES AND SPECIAL DEEP DRILLING AND MILLING CENTRES – TBM roto, TBM flex, TBM mono TBM roto - Machining of rotationally symmetrical workpieces - Used in the automotive industry and medical technology, among others - Customized solutions, automation, handling, workpiece clamping, workpiece cleaning, etc. - Durable machines for parts with maximum precision 24/7 - Optimized accessibility for maintenance and service TBM flex - For individual and series production - Skiving and roller burnishing possible - Machining of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders TBM mono - Very small drilling diameter with large drilling depth - Crane loading possible - Service and maintenance-optimized accessibility - Short set-up times

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL single-roller tools are usually used for roller burnishing. They machine a wide range of complex contours and surfaces such as concave fillets and grooves as well as cylindrical and conical outer surfaces and bores. These tools comprise series EG, EF and FAK. EG tools are divided into tool families EG5, EG14, EG45 and EG90. They burnish cylindrical outer surfaces and bores, conical bores, plane surfaces and fillets. For deep rolling of fillets and thread root radii EF, FAK and FA tools are used. Single-roller tools consist of a tool body equipped with a tool shank, a spring assembly that allows the roller head to move with no play and very low friction. The standard version contains a dial indicator for indirect indication of the spring force. As an option, the tools can be equipped with ECOsense process monitoring for external display of the spring force. The roller head is attached to the flexible, spring-loaded section of the tool body.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quote

SCHNELL SPA

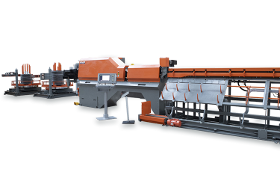

Italy

Fast automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4), equipped with Senso Technology.

Request for a quoteResults for

Roller machine - Import exportNumber of results

71 ProductsCountries

Company type

Category

- Bearings - ball, needle and roller (7)

- Industrial cutting machine tools (5)

- Roller shutters (4)

- Oils, cooking - machinery and equipment (3)

- Packing and packaging - machinery and equipment (3)

- Rolling mills - machinery and installations (2)

- Flour milling - machinery and equipment (2)

- Galvanization - steels and metals (2)

- Metallurgy - machinery and installations (2)

- Polishing - steels and metals (2)

- Abrasives, mechanical (1)

- Aluminium sheets and bands (1)

- Automation - systems and equipment (1)

- Battery chargers (1)

- Bearings, crankshaft (1)

- Bearings, roller (1)

- Bending - steels and metals (1)

- Carpentry - machinery and equipment (1)

- Construction - portable power tools (1)

- Conveyor systems (1)