- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pvd

Results for

Pvd - Import export

PLANSEE SE

Austria

Evaporation coils are available in many different lenghts, diameters, coil lenghts and coil pitches. These resistance heaters with their very high melting points will bring practically any metal to the boil. At the same time, their high corrosion resistance and outstanding material purity prevent any contamination of the substrate. The range includes evaporation coils made of the following materials: — Grain stabilized tungsten (WVM) for the evaporation of aluminum — Tantalum — Molybdenum — Molybdenum-lanthenum (ML) for particularly long service lives

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

PVD Coating Turned Parts by Ming Xiao Mfg Enhance your projects with our exceptional PVD Coating Turned Parts, meticulously crafted by Ming Xiao Manufacturing in China. What is PVD Coating? PVD, or Physical Vapor Deposition, is a cutting-edge coating technique that transforms ordinary turned parts into extraordinary components. It involves the deposition of thin, durable coatings to enhance surface properties. Suitable Materials for PVD Coating Our PVD Coating Turned Parts are compatible with a wide range of materials, including stainless steel, brass, and aluminum. Ming Xiao Mfg ensures unparalleled quality in every coating application. Colors That Captivate Experience a spectrum of possibilities with our PVD coatings, available in a variety of colors. From classic metallic finishes to vibrant hues, customize your turned parts to match your vision.

Request for a quote

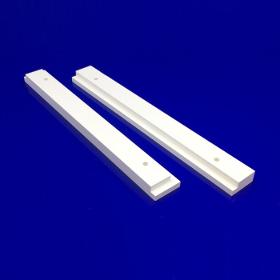

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Boron Nitride is very often machined to isolation components which works in PVD euipments. They are be installed as replacement parts in PVD Magnetron sputtering systems. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina PVD/CVD vacuum coating equipment insulation accessories > Used for ion coating machine, sputtering coating Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

PLANSEE SE

Austria

Tungsten layers are components of the thin-film transistors used in TFT-LCD screens. They are used wherever large screen formats, particularly high image definition and optimized contrasts are needed. But tungsten is also used as a diffusion barrier and a conductive connector in the microelectronics industry. Using the world's largest hot rolling mill for refractory metals, Plansee is able to produce the largest tungsten sputtering target on earth. The benefit to you of large formats: The coating process is more stable and the deposited layers are of higher quality. Thanks to the special forming processes Plansee's tungsten sputtering targets have a density of almost 100 %. As a result, your process benefits from a particularly high level of conductivity and time savings due to the excellent sputtering speeds.

Request for a quote

PLANSEE SE

Austria

Plansee produces material for wear-resistant coatings, adhesive layers, decorative or DLC coatings. Offering compositions tailored for advanced hard coatings with optimized mechanical and tribological properties. Further topics that might be addressed are: enhancing of thermal and chemical stability, adding of functional properties like self-lubrication, self-hardening and self-healing. To adjust the coating characteristics to the dedicated application, Plansee offers its scientific expertise in alloying of targets and cathodes with elements that influence the coating properties as follows: Grain size and morphology, Hardness adaption, High temperature oxidation resistance, Friction coefficient, Thermal stability, Thermal conductivity, Electrical conductivity, Antibacterial properties, Color effects. Offered sputtering targets and arcing cathodes: Titanium-Aluminum Aluminum-Chromium Chromium Titanium-silicon Titanium Zirconium Tungsten carbide Titanium-diboride

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IMETA SRL

Italy

PVD coating is commonly used on seaming chucks made of steel.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner provides a number of proven automation solutions for the automatic loading and unloading of coating carriers for CVD and PVD coatings. The abbreviations PVD (Physical Vapour Deposition) and CVD (Chemical Vapour Deposition) stand for different coating processes. When loading the PVD spears, we differentiate between "single-loading" and "back-to-back loading". In addition to part loading, spacers are loaded onto the spears in addition to the parts. In single-loading, a spacer is located behind each individual insert, whereas in back-to-back-loading, two inserts are placed "back to back" and only then is a spacer loaded. To implement "back-to-back-loading", a turning station is integrated into the machinery. This station is used to turn the corresponding insert by 180 degrees, loading it directly onto the respective spear.

Request for a quoteResults for

Pvd - Import exportNumber of results

8 ProductsCountries

Company type