- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- printing on electrostatics

Results for

Printing on electrostatics - Import export

HANNECARD GROUP

Belgium

Electrostatic assist is used in rotogravure printing to prevent missing dots and ensure higher-quality images with high ink and color density. To guarantee the best and homogenous printing results ever seen, Hannecard developed the unique solutions HanneResist & HanneVision where carbon nano particles are added to its elastomer coatings. Thanks to this unique combination a more homogeneous electric field is generated, offering more accurate attraction of ink on the printed medium and resulting in a superior printing quality. This new technology also better controls the electric charge submitted to the roller, thus lowering the risks for over-charging and sparks. Our HanneResist & HanneVision covering solutions are suited for the decor & cardboard packaging (especially cigarette packaging) printing industry and complies with all electrostatic assist systems (top loading, direct charge (core charging) and side loading)

Request for a quote

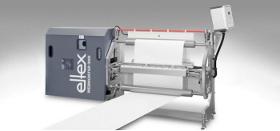

ELTEX-ELEKTROSTATIK-GMBH

Germany

Description In digital high speed printing, paper loses moisture during drying. The moisture loss leads to considerable quality and efficiency issues. Electrostatic remoistening increases the water content in the paper after drying, returning to the level required and thus improves quality and productivity throughout the entire process chain. The contactless remoistening system DIGIMOISTER 1500 can be installed in any new or existing digital high speed press. The pre-charging and the two-substance nozzle technology are patent protected. Advantages: Precise remoistening results at highest production speeds Flat books or signatures Less electrostatic charges on the paper Dimensional stability (no expansion) No broken fibers in the paper Operation: Intuitive operation via a user friendly touchscreen remote control Easy set-up of web width and water amount Low maintenance costs

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

The infeed paper or film web is discharged by the discharge bar to eliminate any existing residual static charges. The nip voltage required in the printing nip is transferred into the conductive layer of the impression roller coating via the impression roller bar. The nip voltage (300 to 900V DC) causes the ink to transfer from the cells to the substrate with point-to-point accuracy and without high impression roller pressure. The discharge bar mounted on the outlet side eliminates any residual charges on the surface of paper or the film. A 2-layer impression roller is used for the ESA Top Loading systems GNH63. The impression roller guarantees the even distribution of the charge in the printing nip.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

In the past, Eltex Remoistening systems have guaranteed high quality printed products mainly on fastrunning and wide machines. The WEBMOISTER 3000 ensures high-quality products in all heatset web offset machines. Using a new nozzle concept, both lighter and heavier grammages can be remoistened at all web speeds with ultimate precision and homogeneity. The new pneumatic atomizing nozzles are capable of applying smallest water quantities without developing waste water. The modular structure of the nozzle bar allows the WEBMOISTER 3000 to remoisten paper webs in widths of as much as 3 meters. In heatset web offset printing, paper loses moisture during drying. The WEBMOISTER 3000 remoistening system increases the water content in the paper after drying, returning to the level required and thus guarantees high quality in all heatset web offset products.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

The POWERTACK electrostatic ribbon tacking system is used in the folders of heatset web offset and publication gravure printing presses. Their task is to electrostatically block the incoming paper ribbons to prevent dog ears. This is a standard feature for new presses and available for retrofitting on all common heatset presses of the world. High voltage generators generate positive and negative high voltage which is passed on to the charging bars mounted in the folder. The positive and negative bars are arranged opposite each other. The ribbons pass between them. The resulting force causes the paper ribbons to attract each other, the air in between is displaced and the ribbons are pressed against each other. As a result, the press can run at a higher speed with better folder accuracy.

Request for a quote

HESKINS LTD

United Kingdom

H6902 printed ESD (electrostatic discharge) floor marking material using the qualities of PermaRoute to make a high definition, industry-specific, printed floor marking material. Utilising the construction of PermaRoute means this material will hold fast, whilst displaying an important message for the area it is intended for.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Printing on electrostatics - Import exportNumber of results

6 ProductsCountries

Company type