- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure plants

Results for

Pressure plants - Import export

KASAG SWISS AG

Switzerland

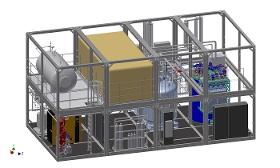

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quote

KASAG SWISS AG

Switzerland

You now operate in an environment where production safety and perfect product quality have top-most priority. You must be able to place unlimited trust in your partners and to demand everything you need. With KASAG as your partner in design, engineering and production of apparatuses, pressure vessels, pressure containers, reactors, heat exchangers, modules and plants for global use, you are on the safe side. Core competences of KASAG: Design, calculation, construction according to diverse regulations, pressure equipment approvals, such as PED (EN13445, AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Manufacturing permits and knowhow for the delivery of pressurised containers, apparatuses, plants to almost all the countries in the world. Welding of stainless steel and special materials such as Hastelloy, Inconel, Duplex Comprehensive spectrum of non-destructive tests Surfaces that meet the highest standards

Request for a quote

APROVIS

Germany

What you can expect from an APROVIS process gas heat exchanger: - Suitable for low and high temperature ranges - Operating pressures up to 160 bar - Compact design for use in confined spaces - Suitable for a wide range of gases - Implementation of customised solutions

Request for a quote

KASAG SWISS AG

Switzerland

Pressure vessels, reactors, Pharmaceutical and biotech pressure vessles, Process containers, storage tanks, Modules, components, plants, High-pressure apparatuses,Heat exchangers, vaporisers, condensers, Cryo pressure vessels, technologies Nuclear technology, Vacuum chambers, vacuum apparatuses, Columns, according to PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Pharmaceutical and biotech apparatuses are calculated and manufactured according to your requirements. Stainless steel and special materials are used in the production. After that, the products are grinded, electropolished and tested using non-destructive testing methods, such as ferrite measurements, used for the determination of the ferrite content, or by using the riboflavin test to measure total discharge and CIP/SIP capability. All materials, methods and processes used have been documented in full in detailed QA documents and can be tracked at any time. You can depend on KASAG.

Request for a quote

KASAG SWISS AG

Switzerland

You now operate in an environment where production safety and perfect product quality have top-most priority. You must be able to place unlimited trust in your partners and to demand everything you need. With KASAG as your partner in design, engineering and production of apparatuses, pressure vessels, pressure containers, reactors, heat exchangers, modules and plants for global use, you are on the safe side. Core competences of KASAG: Design, calculation, construction according to diverse regulations, pressure equipment approvals, such as PED (EN13445, AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) Manufacturing permits and knowhow for the delivery of pressurised containers, apparatuses, plants to almost all the countries in the world. Welding of stainless steel and special materials such as Hastelloy, Inconel, Duplex Comprehensive spectrum of non-destructive tests Surfaces that meet the highest standards

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

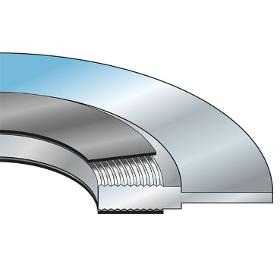

In order to be able to meet the individual requirements of our customers, we offer various types of spiral wound gaskets: For example, you can choose between standard versions with a smooth surface and various special models. All articles are based on a stainless steel strip and high-quality filling materials such as graphite and PTFE, which underlines the excellent quality standard. The spiral wound gaskets of billi are characterized by a constant elasticity during hot-cold cycles. Classical applications in the chemical industry include all types of gas lines, directional valves and pumps. Furthermore, spiral wound gaskets are the optimal solutions for pressure vessel openings in steam systems as well as low and high pressure in nuclear power plants. For the best possible functionality of spiral wound gaskets, the careful considered choice of model is of central importance: the versions with centering ring, for example, assures an ideal fit between the bolts.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e‘ certified immersion heater EEx e T1 – T6 ATEX The “FHK-Exe” type electric immersion heaters are EExe certified. These heaters are custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The range of immersion heaters type FHK-Exe offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust Ex’e’ terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electrical flange type immersion heaters The range of immersion heaters type FHK offers an economic heating solution for process tanks, pressure vessels and similar plant. The standard heater consists of a number of rod elements TIG welded into a process flange. A robust terminal box protects the electrical connections. The number of elements fitted depends upon the media to be heated and the kilowatt rating required. Dependent on application, the heater can be provided with temperature control by contactor or thyristor.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Immersion heater ATEX II 2 G Ex d IIC T3 – T6 ATEX EN60079-0 und EN60079-1 The Exheat „RFA” range of flameproof rod-type immersion heaters is suitable for installation in process tanks, safety showers, engine sumps, pressure vessels and similar plant, located in zone 1 and 2 Hazardous Areas where flammable atmosphere is a group IIA, IIB or IIC gas. They are suitable for heating all process liquids or gases which are non-corrosive to the materials of construction.

Request for a quote

KASAG SWISS AG

Switzerland

Our specialists have vast knowledge and many years of experience in non-destructive testing (NDT) of welding seams, welding constructions, pressure vessels, containers, equipment and plants. We use and offer the following testing procedures for that purpose: X-rays RT Dye penetrant testing PT Visual inspection VT Material testing/ Positive Material Identification PMI Helium leakage testing LT Riboflavin test Pressure tests of up to max. 1000 bar Surface roughness testing Ra/Rz Ferrit measurement Fe Wall thickness measurement Video endoscopy Pressure-loss test (liquid) With KASAG, you remain on the safe side.

Request for a quote

KASAG SWISS AG

Switzerland

We bring your ideas to life KASAG has a high level of competence, with many years of experience in design and construction of plants, apparatuses, pressure vessels, pipes and welded structures. Our engineers can assist you with the following: Strength calculation according to the global regulations, such as PED (EN13445 / AD-2000), ASME (U-Stamp), China Stamp (A1), TP TC 032/2013 (EAC) FEM-calculations (Finite element analysis) and providing proof for overpressure and underpressure, load alteration, earthquake, joint flanges, nozzle loads Consultancy for interpreting and analyses of computation results, material choice, regulatory authorities Constructive, design based on Autocad 2D and Inventor 3D Comprehensive plants engineering, such as compilation of technical specifications, P&I schemes, risk analyses, pipeline/piping planning

Request for a quote

SOJET, LDA

Portugal

Lances for connection to our Plants, for spraying liquids or foams, with tap (T) or branch gun (G).

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ N082, N182 and N782 pressure reducers ensure that a constant outlet pressure is maintained in process plant utilizing the pressure differential.If the pressure rises on the outlet side, the spring force is lower and the valve closes as the spring is raised. The pressure is reduced until the spring force and the outlet pressure are the same. If the pressure falls, the valve opens as the spring force presses against the diaphragm surface via the control aperture. The outlet pressure can be read off a diaphragm-protected pressure gauge (not available for N782) and the spring force adjusted using a set screw as required. - The working pressure can be very easily adjusted using a set screw and secured with the integrated lock nut. If required, the setting that has been made can be lead sealed - The flow-efficient design of the valve body ensures good flow rate values - Control errors are kept to a minimum due to the large control face and the spiral spring

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

Pressurized DUP aim is to disperse the contaminants still present into the stock to a dimension no more visible to the human eyes.

Request for a quote

HASS PIPE

Turkey

HASS produce and supply Steel or Carbon pipes, both seamless and welded, for different purposes: resistance to low or high temperatures, medium or high pressures, for industrial plant appliances, and also suitable for corrosive environments. Our Pipes fulfill the ASME, EN and PED conformity requirements. Hide Text We effect further tests on our products cooperating with certified laboratories and external licensed companies in order to grant the highest level of conformity to the technical specifications required by our customers.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braided of Flexible Expanded Graphite Tape with High Temperature Metal Mesh Reinforcement Practical useful application data: max. temperature in oxidizing atmosphere: +400 °C Characteristics Universal plant wide use in static applications Extrusion stability through ultrafine 10 myh metal mesh reinforcement on each strand Non hardening, good reset capability, coefficient of thermal expansion corresponds to the coefficient of steel High temperature and pressure resistance Suitable for: power plants, petrochemical plants, boiler houses Easy to cut, assemble and disassemble Low coefficient of friction minimizes the adjustment force in valves For valve applications rings should be approx. 25 - 30 % compressed at installation A 66 can be used as bullrings for style A 44, A 44 I and P 60 Die formed rings are recommended Operating range Pressure [p max]: 500 bar Temperature: t = -200… +650 °C pH: 0 - 14 Density: 1.15 g/cm³ Practical useful application data: max. temperature in...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Multilayer construction of expanded graphite with Inconel reinforcement Practical useful application data: max. temperature in oxidizing atmosphere: +450 °C Characteristics Universal suitable, rectangular preformed Sealing tape of expanded pure graphite with Inconel reinforcement Recommended gap width 0.5 mm, maximum gap width 1.0 mm Excellent adaptability on different housing forms and ovality Excellent transformation of axial compression into radial sealing force Operating range Temperature: t = -200… +650 °C pH: 0 - 14 Practical useful application data: max. temperature in oxidizing atmosphere: +450 °C Main application Fittings Valve pressure rings Suitable for Power plant Boiler houses Recommended minimum surface pressure at assembly 20 N/mm 2 Brettschneid Tape Form of delivery 5 x 12 mm in 1 kg Spool approx. 14 mtr 7.5 x 15 mm in 2.5 kg Spool approx. 18.5 mtr 10 x 15 mm in 2.5 kg Spool approx. 14 mtr 15 x 30 mm in 5 kg Spool approx. 9.5 mtr 19 x 30 mm in 5 kg Spool...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

VENTAPP radial fans are used in wood-processing plants where air or loaded air is conveyed under increased pressure. They convey gases, bres, and particles; they are used for wetting, drying or ltering of media. In energy plants, in bre drying, for mat formers and dust extraction systems they form integral parts of Siempelkamp plants. Features Pressures beyond 20,000 Pa Temperatures up to 700 °C Impeller wheel diameters up to 3,150 mm Circumferential speed up to 200 m/s Gas-tight and pressure-resistant design ATEX Advantages High eciency Smooth operation Robust design Low caking, high wear resistance High dependability and operational safety Diverse accessories Maintenance and repair service Variants Drive type Casing positioning Size of all components Angular position Material Colour

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

FRIEDR. GUSTAV THEIS KALTWALZWERKE GMBH

Germany

Our cold-rolled steel strip is mainly used where particularly high requirements have to be fulfilled: -Quality - Dimension tolerances - Mechanical technological properties - Structural compositions - High-quality surfaces As a long-standing partner of the automotive industry we have for decades provided a considerable amount of our cold-rolled steel strip to renowned international automotive manufacturers and their sub-suppliers. There our material is reshaped using punching, bending, drawing and deep-drawing processes. Another important sector of our clients are renowned manufacturers of safety components, electrical equipment, pipes, profiles, pressure vessels, nuclear plants and manufacturers of a wide variety of other industrial products. They all appreciate our comprehensive selection and combination of technical processes and working materials. We support our clients’ product development. With efficient manufacturing processes, the continuous further development of our technologies, broad range of services and comprehensive consulting expertise.

Results for

Pressure plants - Import exportNumber of results

23 ProductsCompany type

Category

- Mechanical engineering - custom work (4)

- Autoclaves (1)

- Biotechnologies (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Conveyor belts (1)

- Filtering equipment and supplies (1)

- Heat exchangers (1)

- High-pressure cleaning machines (1)

- Pipes and tubes, steel (1)

- Pumps (1)

- Seals (1)

- Valves for industrial fittings (1)

- Wood veneer - machinery and equipment (1)