- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure filters

Results for

Pressure filters - Import export

PARSMEGA MAKINA

Turkey

This type of filters are used to separate dust particles from dust-laden air, they can be used with positive or negative pressure, the filter bag is cleaned by 0.5 bar pressurized clean air that does not contain oil and water.

Request for a quote

ERDEM REFRIGERATION

Turkey

DEFINITION AND FUNCTION: The feature of Pressure Filter is filtering of solid particals which taken during the assembly or installation or servicing of a system. ESSF Pressure Filter series are hermetic design for connect on liquid line. The table shows the dimensions and filtration area. PROPERTIES: Maximum working pressure is 45 bar. Minumum flow resistance.

Request for a quote

BÜCHI AG

Switzerland

Metal vessel: 5, 10, 20 liter Pressure: -1.0 (FV) to +6.0 bar Temperature: -10 °C to +200 °C Filter: sintered 8 to 115 micron Material: stainless steel, Hastelloy® C22 These robust and compact pressure filters are designed for filtration, pressurizing the vessel with up to 6 bar pressure. They offer a removable filter basket, a quick opening / closing system and a perfect fit to Buchi pressure reactors, allowing for an easy operation. The filter vessel is jacketed and can be temperature controlled by a circulator. Process connections are standard Tri-Clamp configuration.

Request for a quote

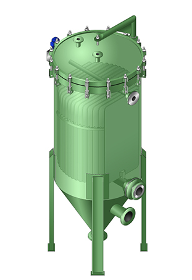

OGE GROUP

Germany

Pressure Filters The Filter is composed of a pressure tank containing the filtering elements and the washing device or dry cake removal system. The filtering elements are vertically mounted cloth covered plates in Stainless Steel/Titanium/PVC/PE/PP (so called leaves) or special candles (made in plastic materials or stainless steel).

Request for a quote

PLANET-AIR GMBH

Germany

The oil-lubricated SILVER-LINE compressor L-S50-25 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 25 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-lubricated SILVER-LINE compressor L-S200-50 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 50 liter air tank.

Request for a quote

PLANET-AIR GMBH

Germany

The oil-free SILVER-LINE compressor OF-S90-15 is standardly equipped with a filter pressure regulator (manual condensate drain) and a 15 liter air tank.

Request for a quote

AHP PLASTIK MAKINA

Turkey

Used for disperse quality of color and black masterbatches in base polymer

Request for a quoteFAUDI GMBH

Germany

Advantages High flow rate No back flushing during the regeneration Easy discharge of the filter cake Short regeneration time Possible use of various filter belts Cleaning station for filter belts New, extremely pressure-stable design Area of application Pressure Belt Filters are used for the filtration of coolants in metal machining processes, preferable grinding sludges from rough-machining. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil and emulsion Filter material filter belt

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The energy costs of a compressed-air system are decisively influenced by the pressure drop occurring during compressed-air filtration. To maintain the required operating pressure, this pressure drop needs to be compensated by correspondingly higher compressor performance. The consequence: increased energy demand, premature wear of the compressor ... and therefore higher costs. The better solution: CLEARPOINT compressed-air filters by BEKO TECHNOLOGIES.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Special FTJ filter fleeces are particularly suitable as precoat or support fleece on horizontal plate pressure filters or plate filters The following precoat agents are used: Diatomaceous earth Bleaching earth Cellulose Cornmeal The FTJ nonwovens Cora®Dot and Cora®Spun effect corresponding savings on precoat agents with extremely fine filtration.

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Every year, millions of tons of household garbage and other refuse are deposited in landfills around the world. Bio-chemical decomposition processes of organic bonds in these landfills produce up to 150 - 250 m of landfill gases per tonne of household garbage. Due to a methane content of up to 60%, landfill gas ranks number six on the list of climate-disrupting methane producers worldwide, but it is also an important source of energy with enormous potential if used sensibly. Up to a content level of approximately 40% methane, landfill gas may still be recovered usefully in modern block heating plants. The important factor in this case is an effective and project-specific pre-cleaning process for the gas. We can help by providing you various gas cleaning systems, gas drying systems, and activated carbon filters, and pressure increasing stations. The components may be used as individual models or delivered as a complete system that is built into a container. Landfill gas...

SOJET, LDA

Portugal

Spraying system with state-of-the-art high-pressure motor pump set equipped with bypass, filter and pressure gauge. Pump equipped with ultra-resistant ceramic pistons. Motors are used with great success in the most diverse industrial activities, in particular in hygiene, humidification and cooling processes. Thanks to their exceptional technical characteristics, these groups can work continuously with low maintenance.

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's own filter technology is innovative and fast-growing. Why are we involved in filter technology? The answer is simple: high pressure cleaning technology using water as an environmentally friendly medium requires a high quality filter and recycling solution. In some cases, traditional filter manufacturers are unable to meet these requirements, which is why KAMAT also offers its own customer-specific solutions in the field of filter technology. High-pressure water cleaning technology has many advantages: A water jet can be used gently on the surfaces to be cleaned, water is generally available as a medium and at the same time is environmentally friendly without extensive delivery costs. When it comes to accessories, high pressure cleaning systems have special requirements that are difficult to meet. For this reason, KAMAT has developed its own customised high-pressure filter solutions. KAMAT high pressure filters are available for operating pressures up to 4,000 bar.

Request for a quote

MIKROPOR

Turkey

"Mikropor manufactures a line of High Performance Compressed Air Filters, Moisture Separators in two different ranges; 50 bar range made of Aluminium. No welding, strong and reliable design. 350 bar range made of Steel. No welding and designed for reliability at very high pressure applications.Mikropor High Pressure Range Compressed Air Filters are NO-weld design. These Filters are built with ample wall thickness and as a result are extremely robust. In-house high pressure test facilities assure the performance. All inner and outer surfaces of 50 bar Aluminium design Filters are Anodised, where 350 bar Carbon Steel design Filters are epoxy electro powder coated."

Request for a quote

MIKROPOR

Turkey

"Mikropor Makroline Air Intake Filters are designed to provide maximum performance for customers with extremely high dust capacity and low pressure drop air intake filter demands.Makroline filters are also suitable for use in higher temperature environments. Mikropor Makroline Air Intake Filters are designed for medium and heavy dust load conditions for applications such as Air Compressors, Construction Machines, Agricultural Machines, Harvesting Machines, etc."

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MIKROPOR

Turkey

Our Oxygen Generators are a Pressure Swing Adsorption (PSA) system supplying pure oxygen to the airline. Zeolite molecular sieve (ZMS), an effective adsorbent, separates oxygen and other molecules like nitrogen and argon gas in the dry air. Non-oxygen molecules are adsorbed by ZMS under constant pressure, so oxygen is produced. Azot Üretim ve Saflaştırma Sistemleri Our Oxygen Generators are two-bed PSA systems filled with ZMS adsorbers. Including filters, a pressure regulator, valves and assemblies; the oxygen generation process is mainly the separation of oxygen and nitrogen from the clean and dry air. Our brand new MOG Series PSA Oxygen Generators offer an extremely economic way to generate the high capacity and purity level oxygen as customer required. We offer our customer oriented solutions for metal, medical, glass, mining, paper industries; ozone systems, laboratories, fishing farms, industrial ovens etc.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GLP - Peumatic top-entry agitator The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the...

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

BDSENSORS GMBH

Germany

PA 440 field display for for the current loop with contacts Features: — field display for pressure transmitter with output signal 4 ... 20 mA / 2-wire or 0 ... 10 V / 3-wire — 4-digit LC display — pressure compensation element with PTFE-Filter Optional Features: — IS-version — 2 contacts — 4-digit LED display — plastic housing Functionality: — free scalable display — switch mode, hysteresis, parameterizable deceleration of the contacts — no external power supply necessary

Request for a quote

BDSENSORS GMBH

Germany

The differential pressure transmitter DPT 200 has been especially designed for the process industry and can be used for level measurement of closed, pressurized tanks, pump or filter controlling, etc. The possibility passes different pressure seals at the DPT 200 adding with different membrane materials to reach an optimal adaptation to the application. Features: — differential pressure von 1 mbar bis 20 bar — static pressure bis max. 400 bar — turn-down max. 100:1 — accuracy: 0.075 % FSO — HART®-communication — output signal: linear or square root extraction — aluminium housing Optional Features: — IS-version: Ex ia = intrinsically safe Version (group II) EX ia= intrinsically safe Version for firedamp mines (group I) Ex d = flameproof enclosure (group II) — LC-Display — stainless steeel housing

Request for a quote

ESCOM ENHANCED SOLUTIONS

Turkey

WiDPr-es is a wireless, batteryless differential pressure sensor developed by ESCOM Enhanced Solutions (ESCOM-ES). WiDPr-es harvests its own power from ambient energy sources, making it a self-powered and maintenance-free solution. The sensor transmits data wirelessly using advanced technologies like Wi-fi, LoRa and Bluetooth Low Energy (BLE) enabling real-time pressure monitoring in HVAC systems, filter condition monitoring, and in other industrial filters, etc. No need for kilometers of cables, wiring, cable trays, trenches, conduits, supports, and no need for batteries, battery replacement and disposal, etc. - Wireless, Batteryless, self-powered, Energy harvesting, IoT - Differential Pressure, HVAC filter monitoring - Bluetooth, LoRa, Wi-Fi - Plug & Forget, Maintenance free, No cable, No Battery

Request for a quote

OMEGA AIR

Slovenia

HF filters are designed for high efficient removal of solid particles, water, oil aerosols, hydrocarbons and other vapours from compressed air systems. To meet the required compressed air quality appropriate filter element (B, P, R, M, S, A) must be installed into filter housing. Optional external condensate drains should be used for efficient condensate draining from filter housing.

Request for a quote

OMEGA AIR

Slovenia

BF HP filters are designed for protection of the downstream compressed air system and equipment against defects and other failures in high pressure applications. Due to their robust welded carbon steel construction, are used for installation in heavy industrial applications with high air flows.They ensure high efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 25 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 6 different grades of filter elements (B, P, R, M, S and A). Optional external condensate drains should be used for efficient condensate draining from filter housing. Fluid group 1 on request.

Request for a quote

OMEGA AIR

Slovenia

HF O2 series of filter housings have been specifically developed for high efficient removal of solid particles from compressed Oxygen applications.

Request for a quote

OMEGA AIR

Slovenia

CHP carbon steel high pressure filters are designed for high efficient removal of solid particles, water, oil aerosols, hydrocarbons and other vapours from high pressure compressed air systems up to 420 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 6 different grades of filter elements (B, P, R, M, S and A). Optional external condensate drain should be used for efficient condensate draining from filter housing.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SFZ are designed for sandwich plate mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for sandwich plate mounting ▪ Available as left or right version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 30 l/min / 8 US GPM Materials ▪ Filter head: Free Cutting Steel ▪ Filter bowl: Cold Drawn Steel Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SMPF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 110 bar / 1.600 PSI. Used together with STAUFF SME series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass valve Clogging Indicator ( available as an option ) ▪ Visual or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SME series Construction ▪ Medium pressure filter designed for in-line assembly Operating Pressure ▪ Max. 110 bar / 1.600 PSI Nominal Flow Rate ▪ Max. 90 l/min / 25 US GPM Connections ▪ Option of BSP or SAE O-ring thread Materials ▪ Filter head: Aluminium ▪ Filter bowl: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quoteResults for

Pressure filters - Import exportNumber of results

108 ProductsCountries

Company type

Category

- Compressors (14)

- Filters, liquid (10)

- Filtering equipment and supplies (7)

- Oiling - machines and systems (4)

- Air treatment - equipment and systems (3)

- Pressure regulators (3)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Dust extraction installations and equipment (2)

- Oil filters (2)

- Precision measuring instruments (2)

- Sterilisation and disinfection - medical equipment (2)

- Water treatment, industrial - systems and equipment (2)

- Air filtration equipment (1)

- Assemblies, hydraulic (1)

- Automation - systems and equipment (1)

- Car body repair shops - services (1)

- Chemistry - laboratory products (1)

- Energy sources, alternative - equipment and systems (1)

- Hygrometers (1)

- Industrial equipment hire (1)