- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses- thermoforming - plastics

Results for

Presses- thermoforming - plastics - Import export

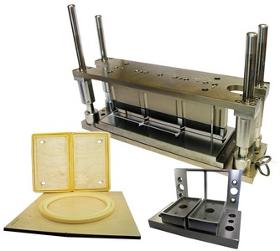

PRO COUPE INDUSTRIES

France

Thermoform tooling for ULMA®, MULTIVAC®, MECAPACK®, CFS® TIROMAT®

Request for a quote

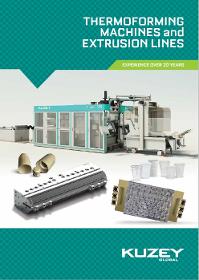

KUZEY GLOBAL

Turkey

Thermoforming machines for disposable food cups and sheet line extrusion , ofset printing machines

Request for a quote

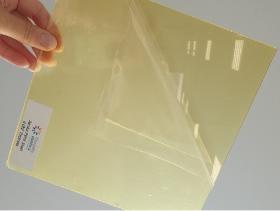

WESTLAKE PLASTICS EUROPE

France

An innovative techno-material combination for aero / defense / rail parts: With a resin manufacturing partner, Arkema, we have succeeded in extruding sheets in an amorphous state (PEKK material already qualified for aerospace) which crystallizes during thermoforming. The fact that the plates are amorphous allows thermoforming deformation and then crystallization offers all the thermal / mechanical / chemical properties of an ultra high performance polymer. Value proposition: advance in the replacement of metal parts / reduce process costs for machined PEEK parts / open the door to the manufacture of large parts (aircraft interior, drones, defense systems, railways, electrical boxes, ducting systems, etc. )

Request for a quote

YENIMAK MAKINA

Turkey

Maximum Mould Size : 650x435mm Maximum Forming Area : 620x405 mm Maximum Cutting Area : 630x405 mm Negative Forming Depth : 120 mm Maximum Sheet Width : 710 mm Minimum Sheet Width : 300 mm Upper Heater Heating Power : 32.5 kW Lower Heater Heating Power : 32.5 kW Continuous Power Consumption : 40 kW Total İnstalled Power : 80 kW Vacuum : 105 m³/h Dry Running Cycle : 60 cycle/min Weight (approx.) : 7000 kg Length : 7000 mm Width : 2300 mm Height : 2500 mm Required Compressor : 3 m³/min Required Cooler : 20000 kcal/hour

YENIMAK MAKINA

Turkey

Maximum Mould Size : 850x650 mm Maximum Forming Area : 820x620 mm Maximum Cutting Area : 820x620 mm Positive Forming Height : 160 mm Negative Forming Depth : 160 mm Maximum Sheet Width : 910 mm Minimum Sheet Width : 400 mm Upper Heater Heating Power : 71 kW Lower Heater Heating Power : 71 kW Continuous Power Consumption : 142 kW Total İnstalled Power : 225 kW Vacuum : 250 m³/h Dry Running Cycle : 60 cycle/dak Weight (approx.) : 14000 kg Length : 10300 mm Width : 2800 mm Height : 3000 mm Required Compressor : 8 m³/min Required Cooler : 50000 kcal

Do you sell or make similar products?

Sign up to europages and have your products listed

RIDAT

United Kingdom

Ridat Semi Automatic (SA) Vacuum Forming Machines offer, as standard high specifications, consistent production and a wide range of standard models and readiness to respond to requests for bespoke specifications. Fully automatic moulding processing sequences with manual placement of thermoformable sheet and removal of the vacuum formed product. Key machine features include: Ceramic heaters with multi-zone heater control for balanced heat Power assisted and timer controlled heater box movement Hinged clamp frame - powered by two air cylinders Mould chamber fully sealed to maintain vacuum pressure High capacity vacuum reservoir and pump for instant vacuum supply Microprocessor Controls and HMI Display CE Mark

Request for a quoteResults for

Presses- thermoforming - plastics - Import exportNumber of results

7 ProductsCountries

Company type