- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision pneumatics

Results for

Precision pneumatics - Import export

KENDRION KUHNKE AUTOMATION GMBH

Germany

Pneumatic timers are used for the precise time control of pneumatic signals in pneumatic circuits or systems. The pressure-independent function of time delay starts when pressure is applied to the control port. After the pre-selected time is elapsed, an internal 3/2 way valve is switched. The pneumatic timer is reset to the initial condition if the control port is vented for at least 300 ms. The adjustable time delay depends on the chosen version and amounts between 0.5 and 180 s. Due to its design the control pressure level must not be below working pressure level. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Pneumatic timers are used for the precise time control of pneumatic signals in pneumatic circuits or systems. The pressure-independent function of time delay starts when pressure is applied to the control port. After the pre-selected time is elapsed, an internal 3/2 way valve is switched. The pneumatic timer is reset to the initial condition if the control port is vented for at least 300 ms. The adjustable time delay depends on the chosen version and amounts between 0.5 and 180 s. Due to its design the control pressure level must not be below working pressure level. As a result of the fire-risk evaluation according to EN 13463-1, the pneumatic timers are not subject to ATEX regulations. This means they may also be used in explosion hazardous areas as defined in IIG/ IID.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

All pipe use quick-change connector. 2. Height and space between filling heads can be changed quick and easy to operate. 3. All filling valve use ESG valve instead of traditional valve by general manufacturer. 4. All filling heads can be diving from the bottom of bottle to start filling. Features 1.1 Suitable material: Wine, beverage,vinegar, daily chemical and something that are low viscous,especially for the foamy liquid. 1.2 This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity instruction pneumatic action. 1.3 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity. 1.4 User may choose the filling volume and decide the filling heads per own production capacity. 1.5 The precision time of the pneumatic valve filling may set to 0.01

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT pressure relief valves for our high pressure pumps ensure optimum working pressure at all times. They can be configured to control pressure either by mechanical pre-adjustment or by remote pneumatic control. We are also able to manufacture many of our pressure relief valves in special materials, making them ideal for the process industry. In addition, our control rods are made from ceramic or stellite, making all our valves highly wear resistant.

Request for a quote

EFFBE GMBH

Germany

Reliable and precise at a pressure difference of 0.01 bar The diaphragm pressure cylinders in EFFBE pneumatic devices work reliably even under the harshest conditions and with no stick-slip effect. The pneumatic cylinders in EFFBE pneumatic devices work reliably even under the harshest conditions and with no stick-slip effect. Even extreme environmental conditions can not affect the performance of our rugged pneumatic devices with diaphragm. EFFBE pneumatic cylinders operate precisely and reliably at a pressure difference of 0.01 bar. As sensitive pressure regulators, they guarantee precise control processes with no stick-slip effect, which as a rule can not be achieved with piston cylinders. Further advantages of diaphragm regulators: EFFBE actuating cylinders are of simple design, maintenance-free and require neither grease nor oil for operation.

Request for a quote

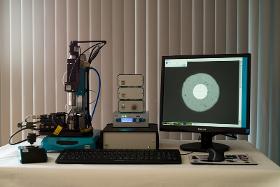

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

stable iron cast stand with coarse dovetail drive and motorized autofocus axis video system with high resolution camera, integrated incident illumination X/Y stage and downholder pneumatic ultra high-precision jaw chuck self developed imaging software with customer specific application program

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labeller \ Label printing and dispensing system for labelling bags Basic concept of the label printing dispenser: Bag labelling with variable data: The EDS620i-VCB label printing and dispensing system was developed for labelling sacks. The label is applied to the bag via a pneumatic label transfer unit. To achieve a precise application result, a pneumatic pressure roller is used. The sack label is then recorded fully automatically via a barcode scanning station and reported to the b+b Siterserver. The basis of the pressure dispensing system is the EDS 620i label pressure dispenser. This is designed for industrial operation and enables you to label your products and their packaging precisely, reliably and quickly using different applicators and label transfer modules.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

Pneumatic Precision Sowing Machines with Disc allow seed to be sowed precisely in the desired sowing range and intra-row distance. It is manufactured with 4-6-8 rows optionally. Seed bed is opened with the help of discs in sowing units. Each sowing unit consists of 2 discs made of special material. It can operate in fields with processed or semi-processed stem remains thanks to cutter discs that can be attached to front side of chassis and disc type sowing units. Because movement obtained from wheel is transmitted to sowing units by shaft mechanism, precision sowing can be performed in intra-row distances. Due to rubber wheels located on both sides of the Sowing Units, precise Depth adjustment can be made in all kinds of soil conditions.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

PNEUMATIC PRECISION SEEDING Machine Precisely sowing seeds in any soil condition in the desired range. Can be used for sunflower, corn, cotton, beet, soy, beans, chickpeas, zucchini and other seeds that require precision sowing. Levers on every unit provide easy adjustment for the sowing depth precision of the machine. Front pressing wheels can be attached for more precision while working with smaller seeds. Missing or excessive seeds are prevented with it’s 12 step precision sowing settings. Sowing row space can be adjusted via bolts. When the sowing is done, seeds can be emptied by the seed tank cap. Fertilizer tank can be added upon request.

Request for a quote

TOSCANO AGRICULTURAL MACHINERY

Turkey

PNEUMATIC PRECISION SEEDING Machine Precisely sowing seeds in any soil condition in the desired range. Can be used for sunflower, corn, cotton, beet, soy, beans, chickpeas, zucchini and other seeds that require precision sowing. Since the machine is in disc type, plant wastes in the field does not prevent the machine from operating. Wheels on both sides of the units adjust the depth precision of the machine. Missing or excessive seed will be prevented with it’s 12 step precision sowing settings. V shaped pressure wheels compresses the seeds and prevents unwanted layers on top. Sowing row space can be adjusted via bolts. When the sowing is done, seeds can be emptied by the seed tank cap.

Request for a quote

FILLTECH GMBH

Germany

The profiFill 4.0 is a highly flexible filling solution for CO 2/N 2O or mixed gasses. Through a pre-programmed filling process, which can be easily configured, adjustable individual solutions and consistent documentation can be ensured. The ProfiFill station is a universal filling station. No matter what cylinder your market requires, our equipment can be adapted to your needs. A clamping unit ensures safe and ergonomic filling. Highlights Ergonomic, durable, fast Lifting unit for short cylinders Pneumatic valve open/close unit Maintenance-free DryLin T-Linear guiding 4 load cells for precision and easy calibration Pneumatic filling head Legal for trade Technical Data: Weighing range: 0-150kg / 0-330lbs. Filling range: 6-50 kg / 0-330 lbs. Cylinders: up to 300 x 1800 mm / 11.8 x 70.8 in. Dimensions: 910 x 800 x 2300 mm / 35.8 x 31.5 x 90.5 in. Weight: approx. 300 kg /661 lbs. Weight Scales & Controls 999 storable cylinder types (PLU) Automatic filling process; automatic closin

Request for a quote

TRIAG INTERNATIONAL AG

Switzerland

Precise positioning Mechanical | Pneumatic

Request for a quote

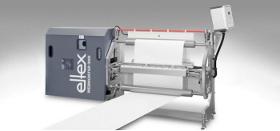

ELTEX-ELEKTROSTATIK-GMBH

Germany

In the past, Eltex Remoistening systems have guaranteed high quality printed products mainly on fastrunning and wide machines. The WEBMOISTER 3000 ensures high-quality products in all heatset web offset machines. Using a new nozzle concept, both lighter and heavier grammages can be remoistened at all web speeds with ultimate precision and homogeneity. The new pneumatic atomizing nozzles are capable of applying smallest water quantities without developing waste water. The modular structure of the nozzle bar allows the WEBMOISTER 3000 to remoisten paper webs in widths of as much as 3 meters. In heatset web offset printing, paper loses moisture during drying. The WEBMOISTER 3000 remoistening system increases the water content in the paper after drying, returning to the level required and thus guarantees high quality in all heatset web offset products.

Request for a quote

AGRIMIR AGRICULTURAL MACHINERY

Turkey

Trailers Cultivators Rotary Cultivators Sprayers Seed Drill Chisel Plows Fertilizer Spreaders Disc Harrows Disc Mowers Disc Ploughs Drum Mowers Feed Mixers Field Sprayers Garden Sprayers Hay Rakes Heavy Duty Disc Harrows Offset Disc Harrows Post Hole Diggers Potato Planters Potato Harvesters Rotary Tillers Rotovators Sickle Bar Mowers Subsoilers Threshing Machine Mounted Sprayers Trailer Sprayers Turbo Atomizers Wheel Rakes Forage harvesters Stone collector Interrow cultivators Soil Tillage,Seed Drills,Fertilizer Spreaders,Crop Protection, Sprayers,Mowers,Hay machinery,Balers,Forage harvesters,Potato planting,Potato harvesting machinery,farm

Request for a quote

BSM MAKINA

Turkey

Designed for 90 assembling of a aluminum profiles Top press and knive movoment is pneumatic system Milimetric ruler system for height and progress of knives Centerin setsquare is pneumatic Discharge button is available for precision adjustment Two pneumatic pedal is using for clamping/li> Polyamide plate profile surface avoid damage 45 side supports arms are available

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The Peter Wolters AC 2000 double-sided batch processing machine is designed for high-precision series production of workpieces. Thanks to its modular design, the AC 2000 can be used as a fine grinding, lapping, honing and polishing machine. Like all machines in the microLine© series, the AC 2000 relies on proven core components such as the high-precision pneumatic loading system, the non-contact micro-measurement control, the powerful drive technology and the PC-supported machine guidance. The software used for this is specially developed by Peter Wolters and enables complete menu-driven and intuitive operation of the machine. For optimum access to the working area, the entire upper part of the machine can be swung out.

Request for a quote

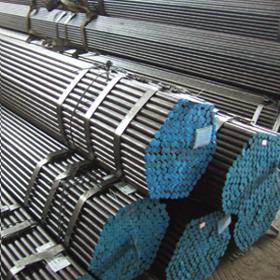

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Precision pneumatics - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Agricultural machines and accessories (2)

- Valves for pneumatic equipment (2)

- Planting and sowing machinery and equipment (1)

- Anti-vibration supports (1)

- Axles, vehicle (1)

- Bottling and filling - machinery and equipment (1)

- Electronic components (1)

- Industrial valves, operating equipment (1)

- Labelling machines (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Measurement - Equipment & Instruments (1)

- Milling - machine tools (1)

- Pipes and tubes, stainless steel (1)

- Pipes and tubes, steel (1)

- Polishing - machine tools (1)