- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pre-pressing

Results for

Pre-pressing - Import export

EGESAN PRINTING AND PACKAGING

Turkey

The inquiries leaded by our Sales & Marketing Department are checked by our Graphics & Design department, firstly. After the controlling process, the draft is sent to our Production Department to be printed.

Request for a quote

FORBO SIEGLING GMBH

Germany

With Siegling Transilon, the gap is often bridged between the classical conveying function from “A” to “B” and an active function in the production process. For example, in the textile industry our processing belts stack thin layers of web, in large bakeries they form balls of dough, in the wood industry they compress chip mat in the pre-press, in dairies milk is coagulated on the belts to form cheese. Here are just a few examples of process operations. Cross-lapping of web layers in the nonwoven industry. High production speed and acceleration of masses while the web is guided directly between the belts places extremely high demands on the processing belts.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Strapping or banding of 3- and 4-point cartons User-friendly and intuitive Format change in less than 2 minutes Change between strapping and banderole in approx. 7 minutes Always the right band for the product - Zero defect 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm / 28mm, either Strap end detection system with automatic discharge of remaining strap DAT 'Direct-Access-Technology' EPP 'Exact Product Path' GreenTech energy concept, low power consumption OPTIONAL: Machine movable OPTIONAL:Bundle stop plate for second strap OPTIONAL: Bundle compensator backside OPTIONAL: Narrow products, min. package width 95 mm OPTIONAL: Fully automatic format adjustment, format change in 30 seconds Bundle stop plate with pre-positioning, no contact with bundle when clearing the bundle, with quick adjustment Bundle press, pre-positioning and electric driven Production data analysis via Ethernet/USB SMART TOUCH – Icon control concept Wear-free,...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Universal strapping of 3 and 4-point folding boxes User-friendly and intuitive Format change in less than 2 minutes Robust and extremely low maintenance ETS - pull-out strapping module High capacity 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap end detection system with automatic discharge of remaining strap DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam EPP 'Exact Product Path' GreenTech energy concept, low power consumption OPTIONAL: Machine movable OPTIONAL:Bundle stop plate for second strap OPTIONAL: Bundle compensator backside OPTIONAL: Narrow products, min. package width 95 mm OPTIONAL: Lateral belts with quick adjustment OPTIONAL: Fully automatic format adjustment, format change in 30 seconds Bundle stop plate with pre-positioning, no contact with bundle when clearing the bundle, with quick adjustment Bundle press, pre-positioning and electric driven Production data analysis via Ethernet/USB SMART TOUCH –...

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The perfect calibration press for the pre-assembly of single-piece fittings.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DE SMET ENGINEERS & CONTRACTORS

Belgium

De Smet Engineers & Contractors has been involved in all steps of the production of vegetable oils from oilseeds crushing for the construction of Edible Oils Plants; in this article you will find a more detailed understanding about the process of vegetable oil extraction: First step: Preparation of the oil containing material prior to solvent extraction Cleaning and Drying The plant feedstock must be cleaned so that foreign matters are removed. This applies particularly to sand/silicate and iron which may damage the preparation plant equipment. For some seeds or for some processes the incoming material moisture must be controlled and adjusted for better efficiency of subsequent operations. Mechanical preparation Most of raw materials needs to broken to reduce the particle size to ensure proper cooking and flaking. They are then heated in cooking / conditioning equipment and their moisture further controlled in addition to be softened before the next mechanical operations. After cooking, heated grits are flaked so that the oil cells are broken and the oil more readily available for further solvent extraction or mechanical pressing. Pressing Oilseeds containing above 20 to 25% (rapeseed, sunflower seeds, cottonseeds...) are generally pressed mechanically in order to extract most or part of the oil available in the feedstock. This operation is done through full pressing for maximum oil recovery leaving up to 5 to 10% in the final cake which is marketed as such or through a low pressure pre-pressing operation producing a cake with higher residual oil content which is then recovered in the solvent extraction plant. Dehulling Oil extraction plants produce a solid finished product in addition to the extracted oil; this product (cake or meal) is normally used as an important component for animal feed recipes. Depending on the meal destination, its protein content often needs to be increased and its fibre content minimized. Such characteristics are generally achieved through decortication or dehulling operations that separate the outer part of the feedstock before extracting the oil. Second step: Solvent extraction of the material suitably prepared Extraction In the solvent extractor, solids (Flakes from the flaking machines or cakes from the pre-presses) are conveyed through the equipment while a mixture of hexane and oil (miscella) is sprayed counter-current. The extractor produces therefore deoiled solids containing solvent and miscella. Desolventization Deoiled solids coming out of the extractor are conveyed to a dedicated equipment that completely removes the remaining solvent while preserving the meal quality: the desolventizer. This apparatus is usually combined with additional sections for drying and cooling the meal to the required storage and market parameters. Miscella distillation Solvent contained in the miscella is completely removed under vacuum and optimum temperature for preserving oil quality. The solvent from the distillation as well as the one removed at meal desolventization stage are then recycled to the extractor. Solvent recovery Since the air entering the process together with material fed to the extractor is laden with solvent when it is removed from the plant it first pass through a specially designed absorption column to limit emission to an acceptable level. Meal treatment The extracted meal is often subject for further treatment, including grinding to obtain the required granulometry or pelletizing to reduce its volume during transport.

Request for a quote

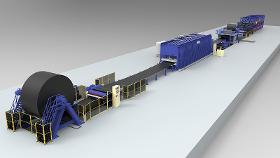

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

Description In digital high speed printing, paper loses moisture during drying. The moisture loss leads to considerable quality and efficiency issues. Electrostatic remoistening increases the water content in the paper after drying, returning to the level required and thus improves quality and productivity throughout the entire process chain. The contactless remoistening system DIGIMOISTER 1500 can be installed in any new or existing digital high speed press. The pre-charging and the two-substance nozzle technology are patent protected. Advantages: Precise remoistening results at highest production speeds Flat books or signatures Less electrostatic charges on the paper Dimensional stability (no expansion) No broken fibers in the paper Operation: Intuitive operation via a user friendly touchscreen remote control Easy set-up of web width and water amount Low maintenance costs

Request for a quote

TECH SLEEVES

Netherlands

Designed to analyse the quality of the sleeve or cylinder, providing insight on its condition. Subsequently, it can be placed with right pre-settings in the press to prevent press downtime. TIR system also stores records for future reference. More details about the TIR Measurement System is available on our website.

Request for a quoteResults for

Pre-pressing - Import exportNumber of results

10 ProductsCountries

Company type

Category

- Conveyor belts (1)

- Electronic components (1)

- Flexography - machines (1)

- Forming, rubber - machinery (1)

- Packing and packaging - machinery and equipment (1)

- Presses, hydraulic (1)

- Textile finishing (1)

- Textile finishing - machinery and equipment (1)

- Textiles - finishing, printing and dyeing machinery (1)