- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plc automation

Results for

Plc automation - Import export

PARSMEGA MAKINA

Turkey

Powering and controlling the motors within the system is done via MCC panels. Contains equipment required for MCC panels, main supply units and remote control. It also has the necessary communication infrastructure for PLC, central automation and SCADA systems. The system automatically protects the motors and all electrical equipment in the field against excessive voltage drops and rises.

Request for a quote

MAGMETT METALL INC.

Turkey

Introducing Powder Coating: A Premier Solution for Impeccable Surface Finishing Welcome to our state-of-the-art powder coating facility, where excellence meets innovation. Powered by a cutting-edge Power and Free conveyor system, our facility operates seamlessly under the meticulous control of PLC automation. Dedicated to delivering unparalleled quality, we proudly hold the prestigious Qualicoat and Seaside certificates. These esteemed accolades validate our commitment to producing profiles in all RAL colors, as well as special colors tailored to meet the unique needs and demands of our esteemed customers. At Powder Coating, we prioritize environmental sustainability. In line with our eco-conscious approach, we have consciously chosen organic solvents-free surface chemicals. By doing so, we ensure that our surface treatment processes remain free from harmful substances, safeguarding the environment for future generations.

Request for a quote

JS INTEGRAL SP. Z O.O.

Poland

JS INTEGRAL manufactures control cabinet enclosures based on technical documentation provided by the customer, complying with the relevant requirements of PN-EN standards, including mining standards. Application • for the installation of electrical equipment: distribution, security, signalling, controlling, measuring and other • for the installation of electronic and automation equipment, including PLC logic controllers and other devices for controlling, visualizing and monitoring of processes in BMS and HVAC systems • to ensure a high degree of protection of the built-in equipment against mechanical damage, dustiness or flooding

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Energy Source → Electrical / Resistance Specifications → Usage at 130 °C → Robotic Options for Sensitive Resin Curing Processes → Custom-Made Design for High Temperatures → 220 ÷ 380 V / 50 ÷ 60 Hz → Homogeneous Heat Distribution → Exhaust Option → Full Automation with PLC → Recipe Management and Trend Tracking → Scada Compatible → Continuous Manufacturing

Request for a quote

GEO TEKNO LTD. CO.

Turkey

Usage and Capacity → Drying and Curing Processes for Sensitive Polymer Production → Customized solutions for the Automotive and Electronics industry Energy Source → Electrical / Resistance Specifications → Process specific, local sensitive temperature control → Temperature sensitivity of ± 2 °C → Fully Automatic Loading Option → Automatic Door → 110 ÷ 220 ÷ 380 V / 50 ÷ 60 Hz → Custom Shelf Designs → Exhaust Option → Full Automation with PLC → Recipe Management and Trend Tracking → Scada Compatible

Request for a quote

PROSAW LIMITED

United Kingdom

The Metlsaw NF range of plate saws are the premier saw for precision sawing of non-ferrous plate from 6mm – 300mm thick. Fully automatic sawing system Up to 12" thickness capacity 50 HP Arbor Motor Positioning (cut to length) tolerance to +/- 0.075mm Surface Finishes to 8 Micro-inch High speed close tolerance cutting Can eliminate/reduce secondary machining of parts Fast set up and part number memory Rapid sawing speeds Full size touchscreen operator interface PLC Controls by Rockwell Automation (AB) Easy Blade Change Available widths of 1.8M – 6M as standard

Request for a quote

OZKOC HYDRAULIC MACHINE CO.

Turkey

Deep Drawing is the most common tecnique for forming either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. The material is held tight between the ram and the blank holder to avoid the formation of wrinkles while the force of the ram pushes the die down to wrap it around the punch. Conventional Deep Drawing Press find use in metal forming, especially in automotive, kitchenware, defense, security and many other sectors. This is the most common tecnique for producing either symetric or asymmetric metal parts. It is a multi-purpose deep drawing method suitable for every structure. In need of pressing speed or cushion adjustment for better product surface , Ozkoc Hydraulic presses have option for speed settings on touch screen via proportional valves. The press automation is PLC supported, and programmed with Siemens S7.1200 software. The press is two push buttons controlled

Request for a quote

ERALP BOILER & ENERGY TECHNOLOGIES

Turkey

Thermal oil boilers are used for meeting thermal energy requirement safely and effectively over 300-320°C degree. Thermal oil systems provide to reach higher temperature that heat transfer liquid cannot reach in the atmospheric pressure. The heating surfaces of the hot oil boilers of Eralp Boiler are manufactured in accordance with DIN 4754 and in spiral bent boiler pipes that are nested in a suitable style. There is no stagnant point in the hot oil circulation. Oil speeds are also secured by flow control systems. As Eralp, we can produce steam boilers working with Liquid fuel, Biomass, Gas and Solid fuel. We increase the system efficiency with the economizer to be added to the back of the boiler. We use steel drawn pipes in accordance with EN 10216-2 norm of European origin in our production as a standard. The system is secured with the automation and PLC control systems used. Energy loss is prevented by reducing the thermal bridges in the insulation.

Request for a quote

AUTOMAZIONI INDUSTRIALI CAPITANIO SRL

Italy

AIC – Automazioni Industriali Capitanio is a global system integrator providing advanced and tailored automation and robotic solutions for the steel industry, with the aim to continuously improve both efficiency, competitiveness and safety of the production processes. With more than 1000 applications worldwide and more than 40 years of history, AIC can boost an unique experience in both greenfield and revamping projects in meltshops, continuous casting machines and long products rolling mills. Thanks to the team of over 70 highly skilled professionals, the company designs, manufactures and commissions turn-key electrical, automation, PLC safety systems and robotic applications, ensuring long-time experience and technical know-how for engineering, AC and DC drives, PLC and SCADA for complete Levels 0, 1 and 2 automation and process control that are the critical issues of Mini Mills. For more information please visit the website www.aicnet.it or send us an email at aic@aicnet.

Request for a quote

HORNER AUTOMATION IRELAND

Ireland

Our range of RCC no-screen controllers combine control, I/O, and networking into a single, integrated package, ideal for applications where a screenless controller is the best fit. The RCC controllers are equipped with a range of digital and analog inputs and outputs – providing users with superior I/O options.

Request for a quote

HORNER AUTOMATION IRELAND

Ireland

3.5” (160 x 128 Pixel) Monochrome Touchscreen Display Improved Logic Scan Rates – 0.8ms/k Logic Real Time Clock (± 90 secs/month) Mini USB B 2.0, Programming & Data access HSC (500 kHz) Operating Temperature range -10 to +60 °C PWM: Models 2,3,4 & 5 – 10 Khz and Model 6 – 65 Khz High Capacity MicroSD Slot (support for up to 32GB) GPRS and 3G Modem Support CAN Protocols – CsCan, CANopen, DeviceNet and J1939 6 Models available, 5 with varying I/O 1 model without I/O

Request for a quote

HORNER AUTOMATION IRELAND

Ireland

Micro OCS Series are embedded I/O controllers. All units feature a built-in logic engine, operator interface, networking and I/O.

Request for a quote

YENIADA FLEXO PRINTING MACHINERY

Turkey

2 Color Online printing machine for production lines. Servo motor driven , SIEMENS 7" Touch Control Screen and PLC controlled automation systems added. Ink pump & Ink tank for each color group included .

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

Line of Machine equipment for the production of wall blocks controlled by PLC automation. Machine with a powerful hydraulic configuration, is able to produce blocks into 140-150 pallets per hour. This kind of Machine produces 12 pieces of 20-th blocks in 1 cycle. The batching plant that provide the Machine by mortar is controlled semi/full automatically that’s up to client. The PARS12 blocks making machine has also the operative and quick mold changing system. It makes the machine ideal for producing different kinds of blocks. General Options Easy to install Easy commissioning and repair Pneumatic and hydraulic cylinders Efficient operation with high productivity Low investment and operating costs Easy to clean Opportunity for long-term work System simplicity Reliable emergency system

Request for a quote

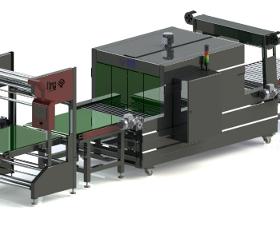

GRIFT MAKINA

Turkey

We have the production of machines in the desired sizes and dimensions. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. There are special production machines in our production. It is designed to pack your desired size products in a precise and fast way. Design and production are carried out according to the desired product type and specifications. It is suitable for products that do not melt with an instant temperature of 200 degrees in the tunnel. It has a sensitive and fast retention feature with SSR switching system. The supply voltage is 380 V/ 50 Hz.

Request for a quote

GLOBMAC GLOBAL BLOCK MACHINES

Turkey

This machine is designed to produce inter locks , blocks. insulated blocks, curbstone it can produce 140-150 pallet per hour 25 interlocks pcs/1 press 10 blocks pcs / 1 press press time is 25-30 seconed it has two system: full automatic and semi automatic it can be use with stacking system or with out stacked pallet must be transport with forklift for machine with stacking system. machine works on the wooden pallet there are two types of mortar reading system. It is manual and automatic weighing system cement water and sand weighn and mortar are mixed all motions on the machine provided by hydraulic system movements on the system will be controlled by PLC automation system via sensors in automaticmachine, machine press number unit of productions , problems on the machine can be seen on the PLC touchscreen panel.

Request for a quote

GRIFT MAKINA

Turkey

Powder products packaging machine. The price changes according to the desired sensitivity and weight. Flour,powder coating,,salep,coffee v.b filling machine for powder groups Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is designed for companies that are just starting out and have low production capacity. It is quite simple and precise to use. As a type of bag, it is suitable for use for ready-made bags. It has automatic feeding and can do fast and precise weighing on ready-made bags. Pieces may vary by minutes upon request and request. A controllable servo motor is available for a fast and precise filling. The desired product weight is obtained by the number of turns of the filling screw. The size and dimensions of the screw may vary depending on the type of product and the desired filling amount. The mixer system located inside the chamber prevents the product from jamming.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GRIFT MAKINA

Turkey

It works with the pneumatic system. Ability to make precise filling with manual 1% accuracy of weight adjustment We are able to manufacture STANDARD production machines between 0-5000 KG. Dec. We are able to manufacture special production machines between 5000-25000 Dec. We have the possibility of customer-specific design. Easy and clear control panel with touch plc screen Automation and mechanical systems are completely manufactured in our structure. It is suitable for precise and fast packaging of granular products. Control is provided by a separate processor independent of the machine. Control is provided by a separate touch screen independent of the machine. It provides possibilities such as automatic cleaning, automatic product feeding and different language options. It is manufactured with different sizes, types, speeds and different number of pads. Compared to these, the shrouds are easy to disassemble and easy to clean.

Request for a quote

TECHTRON

United Kingdom

We offer a state-of-the-art contract chemical blending facility comprising four five-tonne bespoke vessels that have been designed especially for us. Some of the vessels are mounted on load cells for increased accuracy and all are controlled from a fully-automated PLC control panel. The liquid blending tanks have been constructed from food grade 316 stainless steel and are fitted with fully-automated cleaning in place (CIP) regimes for hygiene purposes. Two of the vessels in situ have the unique capability of handling exothermic chemical reactions with inline plate heat exchangers and temperature control systems. These vessels are also fitted with direct acid and base feeds to minimise exposure of the liquid blending personnel. The chemical blending tanks can be fed by a double filtered UV treated mains water feed system, or alternatively, from a full deionised water plant complete with reverse osmosis that is generating water to a pharmaceutical specification.

Request for a quote

EKINEX

Italy

The Ekinex® EK-IA1-TP CODESYS® PLC is an advanced, freely programmable logic module equipped with a KNX interface allowing the simultaneous execution of several complex logic blocks. The devices is equipped with an integrated bus communication module and is designed for rail mounting inside electrical cabinets.

Request for a quoteResults for

Plc automation - Import exportNumber of results

21 ProductsCompany type

Category

- Agglomeration and emulsification machines for the food processing industry (4)

- Automation - systems and equipment (3)

- Brick-making - machinery and equipment (2)

- Chemical industry - machinery and equipment (2)

- Aluminium and aluminium alloys (1)

- Casting, steel (1)

- Containers, metal (1)

- Flexography - machines (1)

- Home automation (1)

- Inorganic bases and compounds (1)

- Oils, cooking - machinery and equipment (1)

- Power stations, oil-fired (1)

- Presses, hydraulic (1)

- Sawing machine tools (1)