- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic resins

Results for

Plastic resins - Import export

NOVELTY STEEL

Turkey

The mold comprises two main parts: the injection mold (A plate) and the ejector mold (B plate), which are also known as moulder and mouldmaker. Plastic resin is introduced into the mold via a sprue or gate in the injection mold. The sprue bushing seals tightly against the nozzle of the injection barrel of the molding machine, allowing molten plastic to flow from the barrel into the mold, known as the cavity. The sprue bushing guides the molten plastic into the cavity impressions through channels on the A and B plates. These channels, called runners, enable the plastic to flow along them. The molten plastic moves through the runner and enters specialized gates, ultimately filling the cavity geometry to create the desired part.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

The Tyrolit diamond cup wheel assortment offers grinding cup wheels for angle grinders in diameters from 100 to 180 mm, ideal for finishing and leveling unevenness on concrete, screed, and other mineral surfaces. They are also popular for bevelling edges on various substrates. Operators can choose from various designs, including cup wheels with high stock removal rates, special cup wheels for even results ideal for bevelling granite slabs, and cup wheels for hard-to-reach places, which are also excellent for floor grinding. Our PCD cup wheels are perfect for removing tough materials like adhesive residues, plastic or resin coatings, and sealants. Available with or without protection segments, they offer a smoother operation or more aggressive machining for stubborn coatings. Other benefits include a long lifetime, no clogging, and high grinding power due to the PCD segments.

Request for a quote

TEMAS GROUP EXPORT PARTNERS

Turkey

DIETHYLENE GLYCOL (DEG) ENERJISUN DEG Purity 99.8 % wt. min Color [Pt-co ] 5 max MEG 0.05 % wt. max TEG 0.05 % wt. max Water 0.05 % wt. max Acidity as Acetic Acid Max 50 ppm Ash Content Max 50 ppm Specific gravity (20/20 ◦C) 1.1175-1.1195 Color Pt-co 10 max Distillation@760 mmHg IBP 242 ◦C min DP 250 ◦C max Introduction Diethylene glycol (DEG) is an odorless, colorless, clear and viscose liquid with a sweet taste, which is produced from the reaction between water and ethylene oxide. In fact, it is the coproduct of ethylene glycol alongside with triethylene glycol (TEG). General Applications Diethylene glycol is used in the manufacture of unsaturated polyester resins, plasticizers and polyurethanes. It is also used as textile lubricant, solvent in textile dyeing and printing, humectant, selective solvent for aromatics in petroleum refining, plasticizer for paper, cork and synthetic sponges, raw material for the production of ester

Request for a quote

AXON CABLE SAS

France

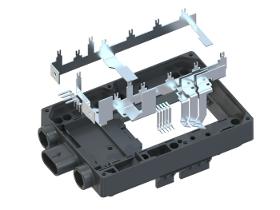

Stamped leadframes are designed to support and accomodate electronic components and PCBA. They can be made with full or selective tin, nickel, silver or gold plating depending on the final requirement. They can be made with pressfit terminals to be inserted into Printed circuit boards. 3 D stamped leadframes can also be designed to your needs. Overmolded leadframes made with high performance plastic resins are designed to support components which are protected in a housing. The overmolding housing allows for the integration of : - the connection area for power components bonding - the output connector to the customer interface - specific terminals to accomodate components to be soldered in electric capacitors for example.

Request for a quote

WEESAFE

France

General manufacturing and maintenance Wood and plastic processing Construction Fiberglass, resin and ceramic applications Light Industrial Cleaning PROTECTION STANDARDS Type 5 EN ISO 139821 Protection against hazardous dry particulates Type 6 EN ISO 13034 Protection against light spray of liquids EN ISO 10732 Protection against radioactive particulates contamination EN ISO 14126 Protection against infectious agents EN ISO 11495 Antistatic garment requirements SIZES M à XXXL FEATURES AND BENEFITS Disposable protective coverall WeePro provides superior protection to dust and liquid jets along. Coverall offers the perfect comfort and durability expected. WeePro fabrics material allows the moisture vapor to escape through the coverall. The ergonomic style pattern allows much greater freedom of movement. Elasticated hood, waist, cuffs and ankles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NITTO KOHKI EUROPE GMBH

Germany

All plastic model. Fluorine contained resin (PFA) body is injection molded. All parts made of fluorine contained resin. Orings in particular are FEPcoated fluororubber with excellent chemical resistance and no rubber elution. Unique new techniques such as “injection molding”, “tube connect system” and “nut type plug mount design” are used to prevent the generation of particles, incessant headache for semiconductor parts manufacturers. To connect with a plug, just push the socket on to it. Disconnection is done in simple and onehanded button operation. Unique “doublelock mechanism” prevents accidental disconnection of socket and plug. Branched tube port improves operability and reduces required piping space. Plugs come with a dust cap.

Request for a quote

MECANUMERIC

France

Fixed table, mobile gantry, 4 cartesian axes, 2 polar axes Refer to the exemples of applications : Electric vehicles parts Parts for subways Parts for trams Bus parts Side windows Aircraft interior furnishing Parts for the train industry Parts for racing motorcycles MILLING EQUIPMENT OPTIMIZED FOR THE MACHINING OF BIG FORM PARTS REALIZED BY THERMOFORMING PROCESS IN FOLLOWING MATERIALS: . Plastics and composites . Synthetic resins . PU and PS foams . Wood and by-products . Aluminium . Brass and alloys AVAILABLE SIZES: Model X travel mm Y travel mm Z travel mm T2515 3100 2100 870 TECHNOLOGY: . Transmission by ball screws on the 4 cartesian axes (X1, X2, Y, Z) . 2 rotative axes (C : +/- 200° and A : +/- 200° as per electrospindle) . Many electrospindles available Numerical control and motoriz ation • SIEMENS SINUMERIK 840DI numerical control : X, Y, Z, C, A.axes Colour screen STN 10.4 inches OP010. Brushless motorisation type 1FK7 with numerical variators. Air-conditioned...

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 3 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 3-stage dedusting system with ionisized air. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Dedusting capacity up to 25 kg/h. Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

HELIO®Clean 2 is a combined conveying-/ mixing-/ and dedusting device for virgin material and regrind. The dust is removed through a 2-stage dedusting system. The compact design makes it ideal for mounting on the feed zone of the processing machine or on a drying container. The separated dust content is sucked out into an external collection bin. Available in 1- or 2-component version, filling is carried out by the integrated compressed air conveying technology with Venturi suction lance(s). Quality: Dust in granules causes lowered mechanical properties of technical plastic resins, leads to problems with surface finish in case of transparent parts, to high rate of rejects basing on smudges or white/black dots in transparent injection moulding parts like for example optical lenses of PC and PMMA. Professional cleaning of resins brings the quality to the original state again and optically perfect parts can be produced.

Request for a quote

STAMIXCO AG

Switzerland

The GXR Static Mixer (Licensee of Bayer, AG) is used for mixing, dispersing and homogenization of viscous materials. It is a high performance motionless mixer design that creates a very high degree of mixing in a short length. It is capable of mixing materials with very large differences in viscosity and volumetric ratios. Mixing Capabilities Mix fluids with similar viscosity Mix high and low viscosity fluids (1 million : 1) Mix fluids with large differences in volumetric ratio (1,000 : 1) Disperse and mix polymers with blowing agents Thermal homogenization Viscosity homogenization Applications Two (2) component viscous materials such as Liquid Silicone Rubber (LSR), adhesives, polysulfide, sealants, epoxy resins, polyurethanes, etc. Plastics Injection Molding Plastics Extrusion Polymer manufacture and processing The mixing elements may be safely pressed out of the housing by pushing on the support ring which avoids any damage to the mixing grid The GXR mixing elements are presently also available in inexpensive plastic construction (50% glass-filled Nylon and polypropylene) Helical Static Mixer The HT helical static mixer pioneered the inline motionless mixing industry over 40 years. It is a cost effective static mixer design with moderate mixing performance capabilities. It is most suitable for use in small diameter turbulent flow and laminar flow applications where the mixing task is simple and where it’s characteristic features of low pressure drop and open geometric structure are best for the specific application. For difficult applications, the high performance GX static mixer is recommended for laminar flow applications. The Helical static mixer is available in metal and plastic construction in a wide variety of configurations and sizes.

Request for a quote

STAMIXCO AG

Switzerland

The GX static mixer has been used successfully for the laminar flow mixing and/or dispersion of viscous fluids for over 35 years. It is a high performance static mixer capable of mixing materials with equal or very large differences in viscosity and volumetric ratio. Mixing is accomplished in a short length with a very high degree of mixing. Mixing Capabilities Mix fluids with similar viscosity Mix fluids with high and low viscosity (1 million : 1) Mix fluids with large differences in volumetric ratio (1,000 : 1) Disperse and mix polymers with blowing agents Thermal homogenization Viscosity homogenization Applications Polymer manufacture and processing. Two (2) component viscous materials such as Liquid Silicone Rubber (LSR), adhesives, polysulfide, sealants, epoxy resins, polyurethanes, etc. Plastics Extrusion Materials of Construction, Housings and End-Connections The GX static mixer can be supplied in most materials of construction, pipe/tube housings with virtually any end connection (Figure #13). GX-P mixing elements in 9.3 - 9.4mm outside diameter size are also available in plastic construction. History of GX Static Mixing Structure The GX static mixer was invented by Bayer AG of Leverkusen, Germany in the mid 1970’s. Bayer used the GX static mixer extensively in their polymer plants and subsequently licensed the design to Sulzer Chemtech of Winterthur, Switzerland who trademarked the design as the SMX* static mixer. Sulzer did a tremendous amount of fundamental high quality R&D work on the SMX structure and commercialized the SMX static mixer in tens-of-thousands of successful installations. The founders of StaMixCo held key technical and management positions in the Koch Engineering (the later Koch-Glitsch)-Sulzer Chemtech team that commercialized the SMX static mixer. Bayer licensed their 2nd generation of the SMX static mixer to StaMixCo which is branded as the GXR structure with integral support ring around the X-Grid mixing bars as described in a previous section of this web site. * StaMixCo is not a distributor of or affiliated with Sulzer Chemtech. SMX is a brand and trademark of Sulzer Chemtech.

Request for a quote

RÜHL FEUERLÖSCHMITTEL GMBH

Germany

GFK Systems PUR Systems Fire Extinguishing Agents Cleaning + Disinfection Infothek About us Contact Products Polyester Foam Resins Polyester Resins Applications Service Quality Newsletter Contact, Glass Fibre Reinforced Plastics Polyester Foam Resins Compared to conventional matrix systems for fibre-reinforced products, UP foam resins offer material and weight reductions of up to 30 % thanks to their micro-cellular foam structure. In simple sealed moulds, glass fibre reinforced plastic components that are smooth on both sides are produced cost-effectively under a vacuum in comparatively short cycle times. The production of sandwich components resistant to bending, with a foam core, and the direct integration of metal reinforcements and threaded elements – for example for large vehicle components – has also proven itself. Typical properties Dense matrix / composite of approximately 0.6–0.7 g/cm³ / 0.7–1.2 g/cm³ Fibre content 20-50% of total weight Moulded part mass per unit area of 3000–5000 g/m² Flexural modulus of elasticity 3000–8000 MPa Bending resistance of 35–185 MPa Impact resistance of 35–65 KJ/m² (with 20–35% glass content) Reinforcing materials: Continuous glass fibre mats Composite glass fibre and fleece mats Natural fibre mats Special formulations and versions Systems with long processing times for very large components Foam resin formulations with elevated dimensional stability under heat Systems for fibre-reinforced components with a high level of characteristics Coordination with gel coat / top coat for surface refinement Flame protection formulations Electrical industry: UL 94 V0 Rail vehicle construction: DIN 5510 (S4, SR1, ST2)

Request for a quote

3DWAYS

Portugal

438.000 Additive Manufacturing Hours Members of TC-206 (AM Norms and Certification) 9 Prototyping Technologies 29 Machines Prototyping is crucial to test hypothesis, validate them and get products to market fast and with low risk. Our extensive prototyping experience allows us to quickly provide you with high quality prototypes in any material you need. What do I get with 3DWays prototyping services? Final, high quality, functional prototypes. Our prototyping services include: 1.Prototypes in plastic, resin, metal and wood 2.Selection and integration of the various prototyping technologies 3.Finishing of prototypes to make them look just like the final product 4.Integration of mechanical, electronic and standard parts

Request for a quote

BRUNNER MUSICA SAS

Italy

20 button Concertina Plastic resin case with scratch resistant finish Key of G-C this diatonic model is available in yellow,light blue, red and green

Request for a quoteResults for

Plastic resins - Import exportNumber of results

15 ProductsCountries

Company type

Category

- Plastics - industrial machinery and equipment (2)

- Chemicals - import-export (1)

- Coupling, pneumatic (1)

- Diamond tools (1)

- Electrical & Electronic Components (1)

- Grinding - machine tools (1)

- Injection moulding of rubber and plastic (1)

- Masks, safety (1)

- Musical instruments and accessories (1)

- Prototypes, industrial (1)