- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic products for the medical industry

Results for

Plastic products for the medical industry - Import export

PEEKCHINA CO., LTD.

China

Dental Disc made with PEEK polymer is a shock-absorbent, permanent solution for implant borne, fixed and removable prosthetic frameworks made with precision through CAD/CAM workflows. 1,Less inflammation Biological complications including peri-implant disease avoided in most patient cases with PEEK prostheses. 2,High implant survival Clinical studies demonstrate a high rate of implant survival in patients with a full-arch implant-supported fixed hybrid PEEK prosthethic. 3,Reduced bone loss Up to 3x-lower marginal bone loss compared to metal framework implants.

Request for a quote

PEEKCHINA CO., LTD.

China

Our wide range of biocompatible polymer materials and compounds are each designed to meet the specific and rigorous demands of implantable medical devices. PEEK materials are tailored to offer superior performance in a variety of applications including spine, orthopedic, trauma, dental and specialty devices. Innovative PEEK materials and our in-depth manufacturing knowledge combined with application expertise supports medical device companies to bring leading edge devices to market and open up new areas of growth.

Request for a quote

PEEKCHINA CO., LTD.

China

Medical-grade, biocompatible PEEK polymer materials Our wide range of biocompatible polymer materials and compounds are each designed to meet the specific and rigorous demands of implantable medical devices. PEEK materials are tailored to offer superior performance in a variety of applications including spine, orthopedic, trauma, dental and specialty devices. Innovative PEEK materials and our in-depth manufacturing knowledge combined with application expertise supports medical device companies to bring leading edge devices to market and open up new areas of growth.

Request for a quote

PEEKCHINA CO., LTD.

China

Medical-grade, biocompatible PEEK polymer materials Our wide range of biocompatible polymer materials and compounds are each designed to meet the specific and rigorous demands of implantable medical devices. PEEK materials are tailored to offer superior performance in a variety of applications including spine, orthopedic, trauma, dental and specialty devices. Innovative PEEK materials and our in-depth manufacturing knowledge combined with application expertise supports medical device companies to bring leading edge devices to market and open up new areas of growth.

Request for a quote

GDI CORPORATION

Bulgaria

We manufacture high-quality components of various sizes and materials, including PP, PE, PET, TPE, silicone, PC, PS and ABS. We have different sized machines and capabilities for 2-component molding.

Request for a quote

PEEKCHINA CO., LTD.

China

Our small size PEEK rods are specifically designed for medical device applications. With precise dimensions and biocompatible properties, these rods offer exceptional strength, chemical resistance, and radiolucency. Enhance the performance of your medical devices with our lightweight and durable PEEK rods.

Request for a quote

PEEKCHINA CO., LTD.

China

Medical-grade, biocompatible PEEK polymer materials Our wide range of biocompatible polymer materials and compounds are each designed to meet the specific and rigorous demands of implantable medical devices. PEEK materials are tailored to offer superior performance in a variety of applications including spine, orthopedic, trauma, dental and specialty devices. Innovative PEEK materials and our in-depth manufacturing knowledge combined with application expertise supports medical device companies to bring leading edge devices to market and open up new areas of growth.

Request for a quote

PEEKCHINA CO., LTD.

China

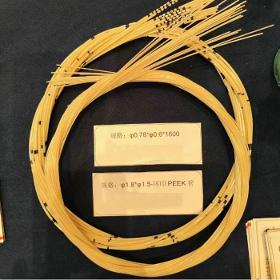

Medical-grade PEEK Tubing for Endoscopic Instruments Our PEEK tubing for endoscopy consumables is engineered to meet the most demanding requirements of medical applications. Crafted with precision, our tubing comes in a variety of sizes to suit your needs, including the specific dimensions of OD 1.4mm with a tight tolerance of +/- 0.02mm and ID of 0.96mm with a precise tolerance of +/- 0.03mm.

Request for a quote

PEEKCHINA CO., LTD.

China

What is PEEK Catheter Tubing? Polyether ether-ketone (PEEK) is a thermoplastic polymer that can be extruded into catheter tubing with desirable properties such as high tensile strength, buckling resistance, good pushability and radiopacity. Why would you choose PEEK medical Tubing? Unlike polyimide, PEEK is melt processable and can be extruded into small diameter tubes for vascular catheters and larger diameter, thin wall tubes for non-vascular applications, such as Natural Orifice Transluminal Endoscopic Surgery (NOTES) devices. What medical devices or procedures is PEEK commonly used in? PEEK vascular catheters provide strong and flexible, small diameter tubing. Non-vascular applications such as endoscopic and laparoscopic procedures often demand larger diameter, thinner wall PEEK tubes.

Request for a quote

AYBERKSAN PLASTIK KALIP SANAYI

Turkey

One of the indispensable elements of the health field is the medical sector. Many devices, equipment, machines and test kits used in this sector have become indispensable elements in terms of quality health care. The importance of domestic entrepreneurs is very great in this sector, where we are 80% dependent on foreign sources. The fact that any investment to be made will reduce our country's dependence on foreign health in the field of health and play a major role in gaining strength in the economic and social field cannot be ignored. As AYBERKSAN Plastik Kalıp Sanayi, we know the importance of being in the medical sector and we are directing our investments in this direction. We respond to the needs of the medical sector with the production of molds and plastic injections for the needs in the pandemic period, test kits with sensitive content, and devices used in disease treatments.

Request for a quote

PEEKCHINA CO., LTD.

China

Medical-grade Biocompatible PEEK PEEK Biocompatible is a cutting-edge solution designed to revolutionize the field of biocompatible materials. Engineered to meet the highest standards of biocompatibility, our PEEK polymers are the ideal choice for applications in the medical and life sciences industries. These materials provide exceptional strength, durability, and precision, ensuring the safety and well-being of patients and the success of research endeavors. With PEEK Biocompatible, you can confidently pursue medical device innovation, implant solutions, and life science projects, all aimed at improving and safeguarding lives.

Request for a quote

RPWORLD

China

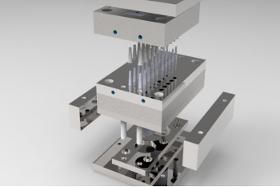

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

RPWORLD

China

RPWORLD Injection Molding service provides high accuracy and consistency for your custom parts. How to achieve that? The combination of our stringent quality control and stage-of-the-art quality inspection equipment ensures the consistency and high quality for your different batch of parts. - Consistent high quality RPWORLD stringent quality control combining with stage-of-the-art inspection equipment ensures the highest quality for your different batch of parts. - 30+ engineering-grade materials 30+ plastic materials in stock, including glass fiber, nylon with carbon fiber, talcum powder, glass bead, and materials of anti-high temperature, flame-resistance, anti-impact, food-grade and medical-class. - Short lead times With automatic equipment working 24/7, our injection molding service help you get custom parts in as fast as 7 days. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quote

GALEX D.O.O.

Slovenia

After defining all product parameters, a test series is created. For creams, the amount is 10 kg, and for tablets 500 tablets. Products from the test series can be used to carry out trials on your customers and to perform product registration. Since the test series is not yet a large production, some things can still be changed and corrected at this stage. This way, we can ensure you are provided with the end product, exactly the way you wanted it to be.

Request for a quote

WESTLAKE PLASTICS EUROPE

France

With the new tightening procedures for cleaning and disinfecting implant ancillaries, PPSU offers an interesting solution guaranteeing a longer life cycle for products. Though it costs usually more than other medical grade polymers (POM, PP), it can nevertheless prove to be more economical in the long term due to its durability. This is especially true for complex designs which are expensive to machine. PPSU does not have any problems with the cleaning & pre-disinfection products. Our material is lot controlled, serialized and is delivered with a certificate of conformance. Coloured resin has been tested under ISO10993/5/10/11/18. The material is not for permanent implantation. PPSU behaves very well after a large number of sterilisation cycles in an autoclave at 134°C/273°F, it can be sterilized through other methods (ETO; gamma, plasma, dry heat). it is polishable for a perfect finish.

Request for a quote

WESTLAKE PLASTICS EUROPE

France

Westlake Plastics manufactures medical grade polymer stock shapes in rods and sheets for orthopaedic trial parts and instruments, dental applications and other surgical tools and accessories requiring medical grade standards and biocompatibility. Within its range of medical grade polymers, Westlake offers: - Polycarbonate (PC) gamma sterilized under its Zelux® GS brand name - Polyetherimid (PEI) under its Tempalux® brand name - Polypropylen (PP) under its Propylux® brand name - Polyphenylsulfon (PPSU) under the Radel® brand name - Ultra High-Molecular Weight Polethylen (UHMW-PE) under its Lennite® brand name These polymers can be used for various medical and surgical tools, knee / hip / shoulder trial parts for orthopaedic implant kits and various other medical grade applications (sterilizable cases and containers) requiring high biocompatibility specifications (USP Class VI and ISO10993).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLEXPLAS

Turkey

Flexplas offers turn-key extrusion lines for Medical Tubing production to the manufacturers in the medical and laboratory equipment sectors. Our customers can produce a broad spectrum of medical hoses out of Flexplas extrusion lines such as flexible PVC medical tubing in O.D. range 2 – 12 mm, PP and PE medical tubing in O.D. range 2 – 4 mm, multi-lumen medical tubing, and more. Flexplas high-speed medical tube extrusion lines are reliable and robust systems to help you serve the medical sector the best quality medical hoses and tubes. Features: *High speed extrusion line for manufacturing of medical tubing *Customized design to meet customer requirements *Master control panel with Smart PLC system with color touch screen. Remote control of the complete line with one master control panel *CE marking certifying full compliance with corresponding EU standards.

Request for a quote

POLYER LLC

Russia

The large line of PP & PS lates we have in our range .

Request for a quote

DEDALUS LTD.

Croatia

Colors: Clear, black or white, dimension can be customized! Can be mounted vertically or horizontally Made from clear acrylic for durability and elegance Universal design for all glove brands Choose from single, double or triple to hold one, two or three boxes of gloves. +Lightweight and durable, easy to use and clean, ideal instrument for a dental office. Colors: Clear, black or white Simple structure, minimalist style, practical for dispensing dental bibs,paper towels, napkins and so on.

Request for a quote

SUPER AMBALAJ / PLASSAN

Turkey

Waste and Medical Waste BAG

Request for a quote

GRI MOLD AND PLASTIC CO.

Turkey

With more than 20 years of experience, Gri Kalıp manufactures molds in world standards. Our company aims to achieve optimal price-quality balance in all projects by adopting the experience and quality standards that it has gained abroad especially in plastic injection molds. Increasing the production capacity of our company, reducing the costs of mold production, is also of great importance for the development of our industry at the same time. Because the greatest cost in mold production is the time of labor and engineering, we aim to shorten the time by producing practical solutions in mold systems with more efficient working principle and not compromising our quality standards or mold materials. For you, Gri Kalıp can be included in the mold making process and you can take advantage of these experiences.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB produces plastic products for the electrical industry. Our company provides that services: mould tool manufacturing, plastic injection moulding, insert overmoulding, DC (dual- component) injection moulding, gas assisted injection moulding, thermoset moulding, plastic blow moulding, decoration, tampo printing, screen printing, wet painting, assembly and packaging, local and international delivery.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB produces plastic products for the vehicle manufacturing industry.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB manufactures plastic products for the furniture industry. Furniture industry companies can give any request to produce plastic parts, plastic furniture parts or any other industrial products.

Request for a quote

PLASPAR PLASTIC INJECTION

Turkey

If you are looking for a company that can cover your plastic production needs, PLASPAR is the right one to choose. We provide plastic production services for all of your needs, with years of experience and customer centered service. Whether you have the mould or not, just provide us the data and we will cover the rest, with competetive prices. Feel free to contact us!

Request for a quoteResults for

Plastic products for the medical industry - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Plastic products for the medical industry (23)

- Moulds, plastic and rubber industry (4)

- Plastic products for the vehicle manufacturing industry (4)

- Plastics - industrial products (3)

- Bottles and jars, plastic (1)

- Packaging contractors (1)

- Plastic products for the electrical industry (1)

- Plastic products for the electronics industry (1)

- Plastic products for the furniture industry (1)

- Plastics moulding (1)