- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plasma cutting

Results for

Plasma cutting - Import export

NOVELTY STEEL

Turkey

Plasma cutting operates by firing an electrically ionised heated gas (plasma) out of a nozzle at a high speed towards the metal. This will form an electrical ark within the gas. High level of heat is generated as electricity from the nozzle travels down this plasma. This heat melts the metal where cutting is achieved. Plasma cutters can cut stainless steel, aluminium, brass and copper along with mild steel. It’s particularly ideal for thick metal, up to 50 mm. If cutting highly reflective or very thick sheets of metal is required, plasma should be the ideal cutting method. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

ESTIMET SP Z O.O.

Poland

We use plasma to cut sheet metal. We have state-of-the-art equipment that allows us to precisely process materials such as carbon/structural steel, stainless steel, heat-resistant steel and aluminum, among others. Our machine allows us to cut parts that fall within the dimensions: 6000 x 2000 mm in length, max thickness 40 mm. During the plasma cutting process, melting of the material takes place. It is then ejected from the slot by a highly concentrated plasma arc with high kinetic energy. The plasma method can be used to cut large-size parts. Like laser cutting, it provides high precision. TYPE OF MATERIAL CUT (max thickness 40 mm): - carbon steel / structural steel - stainless steel, heat-resistant - aluminum

Request for a quote

ILK IHRACAT AS.

Turkey

Shape Your Project with Precision Plasma Cutting Service In industrial design and manufacturing projects, accurate cutting is a cornerstone of success. This is where our plasma cutting service comes into play, offering the ability to shape materials like metal, aluminum, steel, and more with precision. Get a Quote Now! Discover our plasma cutting service that offers the most precise and rapid solution for your projects. Share your needs, and our expert team will provide you with the best solution. For more information, you can visit our Contact page. Who Are We: Steeling.Net carries out partner marketing activities in the Turkish metal industry. Our partner manufacturers are companies that specialize in sheet and steel processing and have a wide product range.

Request for a quote

ILK IHRACAT AS.

Turkey

Shape Your Parts with Our Cut To Size Services In the manufacturing sector, accurately cutting parts to the right measurements and shapes is of vital importance for product quality. Through our professional precision cutting services, we execute your cuts with the utmost precision. Benefits of Cut to Measure Precision cutting is a technique that allows for accurate cutting of various materials like metal, wood, plastic, and more. With our expert team and state-of-the-art equipment, we cut your parts perfectly. Our Services: Laser Cutting: We accomplish even the most intricate designs with high precision using laser cutting technology. We provide laser cutting service between 0,5-70 mm thickness. Plasma Cutting: By cutting thick materials with a plasma, we achieve the best results.

Request for a quote

INOTECH MACHINING SRL

Romania

We offer laser cutting and plasma cutting services for multiple metal materials: - Aluminum, - Steel, - Stainless steel, - And copper. Our laser cutting machines: BYSTRONIC BYSPRINT FIBER 4020 4000W - Maximum dimensions of the material to be cut: 2000 x 4000 mm - Power: 4,000 W Maximum cutting characteristics: - Aluminum up to 15 mm thick - Stainless steel up to 15 mm thick - Steel up to 20 mm thick - Brass up to 8 mm thick - Copper up to 8 mm thick - Accuracy: +/- 0.01 mm BYSTRONIC BYSTAR 3015 - Maximum dimensions of the material to be cut: 1500 x 3000 mm - Power: 3,000 W Maximum cutting characteristics: - Aluminum up to 5 mm thick - Stainless steel up to 10 mm thick - Steel up to 15 mm thick - Accuracy: +/- 0.01 mm

Request for a quote

INOTECH MACHINING SRL

Romania

We offer laser cutting and plasma cutting services for multiple metal materials: - Aluminum, - Steel, - Stainless steel, - And copper. Our laser cutting machines: BYSTRONIC BYSPRINT FIBER 4020 4000W - Maximum dimensions of the material to be cut: 2000 x 4000 mm - Power: 4,000 W Maximum cutting characteristics: - Aluminum up to 15 mm thick - Stainless steel up to 15 mm thick - Steel up to 20 mm thick - Brass up to 8 mm thick - Copper up to 8 mm thick - Accuracy: +/- 0.01 mm BYSTRONIC BYSTAR 3015 - Maximum dimensions of the material to be cut: 1500 x 3000 mm - Power: 3,000 W Maximum cutting characteristics: - Aluminum up to 5 mm thick - Stainless steel up to 10 mm thick - Steel up to 15 mm thick - Accuracy: +/- 0.01 mm

Request for a quote

VOSSE SP. Z O.O.

Poland

Plasma (gas) cutting service is an efficient metalworking method that is used in many industries. It uses a high-temperature electric arc to melt and cut through metals, resulting in a precise and clean cut, even for thick materials. It is an extremely versatile process that can be used for both straight-line cutting and the cutting of intricate shapes, making it invaluable in the production of metal structures, machine components or even artistic works.

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

* Plasma cutting up to 30mm * Flame cutting up to 100mm Due to our quick response, we cut materials in-house. We provide support and advice to customers for better material utilization and consequently lower costs. Maximum cutting dimensions are 6x2m.

Request for a quote

MAHERAS LTD.

Bulgaria

We have Plasma cutting machine. We can cut details from all kinds of steel.

Request for a quote

PETROLINE LLC

Ukraine

We perform plasma cutting of varying degrees of complexity. We adhere to a responsible approach to fulfill each order and guarantee the highest quality of products obtained. Or company specializes in: • production of various parts for the subsequent manufacture of metal constructions; • cutting of metal according to the sample, sketch or drawing provided by the customer; • execution of outlines and drawings according to sketches provided by the client; • performing metal cutting efficiently to minimize residuals

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

We provide plasma - laser cutting services with our modern machinery park.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Made on customer demand, they can be produced in different sizes and according to certain quality standards.

Request for a quote

RAMAZAN AYCAN SAC VE CELIK ISLEME MERKEZI SAN. VE TIC. A.S.

Turkey

Cutting of steel, dkp, stainless, aluminum, copper, brass and galvanized sheets are performed with plasma cutting machine. Our machines can perform plasma cutting from 1 mm to 35 mm. As Ramazan Aycan Inc., we provide plasma cutting services to cut sheet in desired sizes and thicknesses according to the demands of our customers; we provide you with guaranteed services with our expert staff.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 440i neo is one of the most flexible and most powerful high-precision plasma cutting units worldwide. Its wide cutting range from 0.5 mm to 120 mm i means considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 440i neo is ideally suited for steel service centers, steel producers and distributors. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 161i neo is the latest high-precision plasma cutting system for the cutting range between 0.5 mm and 50 mm. Equipped with the soft-switch inverter technology, it offers a wide range of possibilities for cutting and marking thin and medium-sized sheets. It meets the requirements of the metal and container construction industries, the engineering and automotive industries and many other sectors. The HiFocus 161i neo can be combined with 2D as well as 3D CNC-controlled guiding systems, i.e. gas cutting systems, robots and pipe cutting systems.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 360i neo is one of the most flexible and most powerful high-precision plasma cutting units. Its wide cutting range from 0.5 mm to 80 mm means a considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionionality on the market. The HiFocus 360i neo is ideally suited for steel service centers, steel producers and distributors because it can be combined with 2D or 3D CNC-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KJELLBERG VERTRIEB GMBH

Germany

The plasma cutting system HiFocus 600i neo sets new standards for plasma cutting: materials with a thickness from 0.5 to 160 mm can be cut precisely. Furthermore the system is suited for marking, bevel and underwater cutting. Consisting of two power sources (HiFocus 360i neo, power module HiFocus 600i neo) the system achieves a maximum cutting current of 600 A and can be adapted to guiding systems. With HiFocus neo the user benefits, compared to competitors, from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to the optimised technology, the consumables are handled gently and the plasma cutting process is more efficient. The plasma cutting system HiFocus 600i neo uses the approved Contour Cut technology for cutting contours, holes and webs fast and precisely in mild steel.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 80i is the smallest high-precision plasma cutting unit worldwide. It covers a cutting range from 0.5 mm to 25 mm. It provides highest quality when cutting thin and medium-sized sheets with an unbeatable price-performance ratio. A wide range of special torches and various fields of application in connection with robot systems make it ideal for the automotive industry.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 280i neo is one of the most flexible and most powerful high-precision plasma cutting units. It covers a cutting range from 0.5 mm to 70 mm. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 280i neo is ideally suited for steel service centers, steel producers and distributors.It can be combined with 2D or 3D cnc-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient. The HiFocus 280i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

Request for a quote

MVD MACHINERY

Turkey

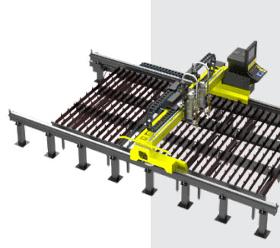

P-Series Plasma machines are used for cutting thick metals, It is a reliable and robust plasma source. Hypertherm cutting head, CNC control unit and power source provides precise and high quality cutting. P-Series Plasma machines are designed for precision cutting, High Performance, High Speed It can be equipped with Pipe cutting, 5 axes beveling head, multi plasma heads and Oxy cutting heads.

Request for a quote

ATOM KARINCA LASER

Turkey

CUTTING CAPACITY 300 mm Mild Steel 50 mm Stainless Steel 50 mm Aluminum plasma cutting We provide high-quality results in cutting various thicknesses of mild steel, stainless steel, and aluminum materials. We also provide beveling up to 45 degrees and marking.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

Do you need a compact machine which is flexible and easy to use for your daily work? The MultiTherm® Eco is the perfect universal machine for oxyfuel and plasma cutting. Efficient cutting productivity due to a high level of automation and easy set-up and operation produces quality components - quickly and efficiently.

Request for a quote

KASAG SWISS AG

Switzerland

With our highly modern 3D plasma cutting equipment, we undertake plasma cuts of spherical bottoms/heads, dished boiler heads, pipes, profiles and metal sheets in material thickness of 1 - 50 mm. Metal sheet change:2,000 x 3,000 mm (2,000 x 6,000 mm) Pipes, profile:diameter 30 - 500 mm / length 3,000 mm (6,000 mm) Heads, cones: up to diameter 2,500 mm Material thickness:1 - 50 mm

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

he SmartBlade has been conceived for use in small workshops with limited space available and offers all the advantages of a fully-fledged plasma cutting machine. The machine concept focusses on the operator and flexible working –the simple operation ensures for you the desired cut quality for all tasks. The SmartBlade is the economical entry level machine for everyone who demands the best quality even with complex vertical cuts.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

The SmartBlade has been conceived for use in small workshops with limited space available and offers all the advantages of a fully-fledged plasma cutting machine. The machine concept focusses on the operator and flexible working –the simple operation ensures for you the desired cut quality for all tasks. The SmartBlade is the economical entry level machine for everyone who demands the best quality even with complex vertical cuts.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

You value flexibility? The MultiTherm® is multi-talented thanks to its variety of equipment options to fulfill your current and future application requirements. The MultiTherm® is a versatile cutting machine for plasma cutting, laser cutting, oxyfuel cutting and as well as in combination. The MultiTherm® is versatile and efficient with highest requirements concerning top quality and productivity.

Request for a quoteResults for

Plasma cutting - Import exportNumber of results

88 ProductsCountries

Company type

Category

- Plasma cutting machines (26)

- Cutting - steels and metals (16)

- Cutting - machine tools (5)

- Harvesting machinery and equipment (3)

- Industrial sheet metal work (3)

- Oxygen cutting - machines (3)

- Turning - steels and metals (3)

- Steels and metals - welding and brazing (2)

- Casting, steel (2)

- Milling - machine tools (2)

- Milling - steels and metals (2)

- Laser - cutting and welding machines (1)

- Bakery and confectionery industry - machinery and equipment (1)

- Bending - steels and metals (1)

- Filtering equipment and supplies (1)

- Grinding - steels and metals (1)

- Import-export - construction and publics works (1)

- Mechanical engineering - custom work (1)

- Metal structural work (1)

- Stainless steels (1)