- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plant testing

Results for

Plant testing - Import export

KASAG SWISS AG

Switzerland

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Displacement and all mechanical values which can be converted to displacements (e.g. compressive and tensile force, strain, torque and vibration) may be measured by this DC/DC displacement sensor. Typical application areas are the measurement of displacement and strain on machines, servo systems, vehicles, on test plants, in civil engineering and tunnel construction. An integrated maintenance-free electronic and a high-level DC output signal provide an easy handling without any problems. Displacement sensors of series 87240 convert a displacement into an analog electrical signal. They consist of a differential transformer with moveable core, an oscillator and a demodulator. These components are integrated and encapsulated in a cylindrical housing made of stainless steel. The sensors are energized by DC voltage, which is converted to AC by the oscillator and brought to the primary coil of differential transformer.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Inductive displacement sensors of this series measure linear displacements and indirectly all mechanical values convertible into displacements by additional equipment (i.e. tension and compression forces, extension, torque, vibration). The sensor body equipped with a connector has an outer diameter of only 8 mm and therefore is especially well suitable for the integration in dimensionally restricted structures. Typical application fields are displacement and extension measurements on: —Machines —Servo systems —Motor vehicles —Test benches —Production plants The cylindrical case made of stainless steel, houses a differential transformer (LVDT). It consists of a primary and two secondary coils with axially moveable core. A displacement of this core changes the magnetic induction of the coils. The INLINE carrier frequency amplifier converts the displacement into a direct proportional electrical DC voltage.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

OUR IN-HOUSE TEST PLANT AND LAB In order to ensure the high quality and long service life of our agitators, we have set up an in-house plant for testing our agitators. At the end of the manufacturing process, all of our agitators undergo a specific test procedure with a final test run. Here, we can test agitators with a shaft length of up to twelve meters. When designing our agitators, we use fluid mechanics simulations in our in-house laboratory. All Geppert mixing systems are delivered with O&M Manual and worldwide technical service.

Request for a quote

ESCOM ENHANCED SOLUTIONS

Turkey

In the pursuit of advancing technology, various sensors undergo rigorous testing at power plants managed by ESCOM Power Plants Engineering Services. The ESCOM Enhanced Solutions R&D center is at the heart of this innovation, spearheading the design, development, and manufacturing of these sensors. LiTeM stands as a testament to ESCOM-ES's commitment to innovation and functionality, having been meticulously assembled and tested at one of the renowned power plants. The test results affirm LiTeM's superior efficiency, marking it as a revolutionary development specifically crafted to enhance the performance and safety of internal combustion engines.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ SUMONDO® single-use diaphragm valve consists of a diaphragm valve body and a manual or pneumatic operator. The single-use diaphragm valve body has an internally welded diaphragm. The single-use diaphragm valve body is fastened to the operator using a clamp. The valve body and the operator are locked using a defined closing and opening procedure. After use, the single-use diaphragm valve body and its diaphragm can be removed from the operator and disposed of. The operator can be used multiple times and remains in the plant. — Tried and tested actuator design — Impact resistant, corrosion resistant — The diaphragm valve body meets the purity requirements of the pharmaceutical industry (USP 85, USP 788) — Integral optical position indicator — Validation Guide on request — Gamma-sterilizable valve body

Request for a quote

XI'AN GREENSPRING TECHONOLOGY FRANCE

China

Product Name:POMEGRANATE EXTRACT POWDER Plant Part: Fruit Test Method: TLC Specification: 10: 1 4: 1 Appearance: Red powder Solubility: Better water solubility Type of Extraction: Grain Alcohol Certified: Kosher, Halal, Haccp, ISO

Request for a quote

SOUNDSORBA LIMITED

United Kingdom

Steelsorba is a high specification acoustic solution for sound absorbing industrial panel for walls and ceiling linings. It is designed to reduce the problem of noise reverberation. Steelsorba panels are a sound absorbing material resistant to mild impact and are simple and quick to install. All component parts of the system can be modified at installation to suit. Suitable areas for treatment are factories, workshops, plant rooms, test bays and other industrial environments. Acoustic Performance Installation Walls Odd leg U channels are plugged and screwed to the wall. Insert the panel into top channel and push panel flush to wall then lower into bottom channel. Use bottom channels vertically as capping to cut wall ends. Ceilings Odd leg U channels are plugged and screwed to the soffit. Insert the panel into top channel and push panel flush to soffit then slide into bottom channel. Use bottom channels as capping to cut ends. Use pop-rivets or screws to hold panels at ends as...

Request for a quote

CARBOMECH SP. Z O.O.

Poland

Comprehensive Composting Plant Construction Services We offer professional services for the construction of composting plants for waste processing. Our solutions are tailored to the individual needs of our clients, ensuring efficiency, compliance with environmental regulations and operational safety. Scope of Services Construction and Installation: - Site Preparation: We perform earthworks, ground leveling and necessary foundations to prepare the site for the construction of a composting plant. - Installation: We install all necessary technological equipment and systems, including conveyors, composting chambers and aeration systems. - Start-up: We provide full start-up of the composting plant, including testing of all systems and their calibration to ensure optimal performance. Ventilation and Control Systems: - Installation of Ventilation Systems: We install advanced ventilation systems that provide appropriate air conditions for the composting process.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

Systems & Modules SMS designs, manufactures and supplies complete systems & modules for evaporation, drying and membrane applications. Our scope of supply includes: Consulting / Feasibility Studies Pilot Test Process Design Plant Engineering Project Management Procurement / Manufacturing / Delivery Erection / Installation Start-Up / Commissioning After-Sales Service Skid-Mounted Modules For more than 40 years SMS has been supplying skid-mounted units for the benifit of our customers. The skids are fully assembled, including piping, wiring and testing in the SMS Workshop or in our partners´ workshop. The modular design significantly reduces the required amount of work for assembly and start-up which minimizes the downtime of the existing plant equipment and - as a result - just minor effects occur on the current production.

Request for a quote

COMPUR MONITORS GMBH & CO. KG

Germany

Tracer – Leak detection in the ppb range Application The Tracer has its strength where other methods of leak detection would fail, because they have cross sensitivities to other gases. Such selectivity is requested in plants using or producing extremely toxic substances. These plants always have a „Zero Emission Policy“ in force. Here high sensitivity in combination with good selectivity is required. Sensor technology Electrochemical sensors can be designed to be very selective and sensitive at the same time by the right material choice for electrodes and electrolyte. These sensors will not respond to less dangerous substances that might be around in the plant such as hydrocarbons, carbon monoxide, hydrogen or even humidity. A detection limit of Phosgene as low as 2 ppb is no problem for this sensor technology! The Tracer is capable to detect even the smallest traces of toxic gases. The detection limit is in the low ppb range depending on the substance to be detected. As a leak detector might be exposed to very high concentrations, it must not be used as a personal monitor. To avoid it being abused as such, it displays no concentration, but only a dimensionless figure or a bar graph. Using the Tracer To locate a leak, move the sample intake along the surface to be inspected. The measured value will increase when a leak is approached. The display can be selected between bar graph and digital. A control tone and LED will increase in frequency with increasing measured value similar to a Geiger counter. The Tracer will protect itself from poisoning. If the measured value goes out of range the pump will go off and start again when it drops below 95% of the range. The graphic display is easy to read. At night or in dark places in the plant a backlight can be switched on. Consumables such as sensor, filter or sampling probe can easily be replaced without tools. Field test results – the high range version The first tests in plants have proven that an ultra-low measuring range does not always do the job. Therefore Compur Monitors has completed the Tracer product range by a new HIGH range version. It uses an orifice in front of the sensor increasing the measuring range by a factor of 20. The user can do that without changing the amplifier adjustment. All it takes is just replacing the LOW range sensor by a HIGH range sensor and so cover a measuring range from the low ppb range up to the two digit ppm level! The Tracer comes with 4 AA size disposable batteries. This version is not explosion proof. Ex Version Upon request the tracer can be delivered in an explosion - proof version with rechargeable batteries.

Request for a quote

SIM AUTOMATION GMBH

Germany

- Quality control and safeguarding - Individual test values and criteria - Customer-specific measuring and testing plants - Single measuring systems with manual assembly - Fully integrated and automated testing plants using robots - Optical, acoustic or electrical systems with/ without parts contact, data preparation, analysis Measuring and testing systems we were involved in: - Camera systems with corresponding image processing - Part recognition, positioning, color and surface examination, checking for damages - Optical / tactile / ultrasonic tests using sensors and displacement measurement systems - Leakage and pressure tests - Inspection and monitoring of filling level - Run-out properties and accuracy - Backlash measurement - Electrical tests and measurements - Electrical values, check measurements, switching and opening properties Used in all branches: e.g. pharmaceuticals industry, medical engineering, cosmetics, electronics and automotive industries.

Request for a quote

PERO AG

Germany

PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. PERO Centre of Competence in Königsbrunn in a dedicated area measuring 1,100 m², there are more than 15 separate units available for parts cleaning tests. In manufacturing plants, parts cleaning is one of the key activities along the production line. The productivity of a manufacturing plant is determined by the availability of the cleaning technology. At the PERO Centre of Competence, PERO specialists work together with operators to develop the cleaning method that best suits their needs.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

In the field of minimum application unit we can offer different application units such like floating knife, mini kissroll, knifeoverroll and screen or predosed kissroll units. These units offer the following advantages compared to a traditional padder process Lowaddon technology with a fabric moisture of 60 g/sqm, lower water consumption and thus high energy savings during the subsequent drying processes, low residual liquor (2.5 litres per metre working width) and thus fewer chemicals which have tob e disposed of during a batch change. Test can be carried out at any time on our test plant in our Technology Centre in Germany.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp's continuous saws are a tried-and-tested solution for plants with highest outputs. The saw throughput does not depend on the number of cuts and is therefore superior to other cutting solutions, particularly for large master boards. Continuous saws also permit in-line quality grading. This means that the combined sanding and saw line is able to deliver sorted stacks of nished boards from the master boards in a single stage of work. This allows investment and operating costs to be minimised. The cut-to-size saws may be combined in-line with a sanding machine or set up separately just as a cutting system Features and functions Continuous saws for longitudinal and horizontal cuts Scoring unit and main saw blade for top-quality edges Reliable guiding of the board using chains and/or rollers to ensure accurate cutting Trimming of the edges directly by the tool, no additional conveyors and follow-up work required

Request for a quote

KONTAKT LLC

Ukraine

The gas receiver units are special equipment for the CNG filling stations, manufactured exclusively according to the customer’s technical specifications and designed to expand the processing capabilities of the CNG filling stations. The following must be obligatorily agreed with the customer: Supporting metal construction of the cassette of cylinders. Piping design. The details of the distribution unit. Cylinders for the receiver units, as a rule, are provided by the customer, have a certificate of conformity and a registration certificate of the corresponding model. On delivery of the completed equipment to the customer, the Kontact LLC plant provides: Plant design tests. Assembly, adjustment and testing at the customer’s facility. More information on our website.

Request for a quote

ESMO AG

Germany

In the production phase, our experienced engineers will implement our innovative ideas in turn-key plants. The close coordination between our project managers and our assembly teams ensures efficient and high-quality production results. After the successful completion of the test phase, the plant will be handed over to you. Safety certificates and declarations of conformity (CE marking) will be issued upon your request. Electrical Assembly esmo automation provides and installs electrical cabinet systems and components as per customer specifications. We will check your equipment prior to commissioning, and support you in any maintenance issues as well. Furthermore, we conduct safety checks and adapt obsolete facilities to current standards. Design + Engineering We plan and design control cabinets and create wiring diagrams for your individual applications. With the support of professional tools, such as EPLAN P8, we develop customized designs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTLAKE EUROPE

Belgium

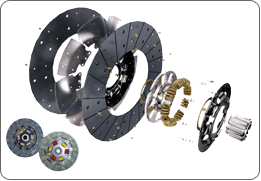

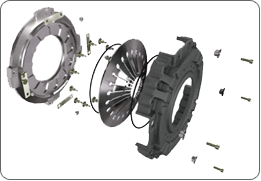

Design and production facilities for all types of car, light commercial and heavy commercial vehicle clutch plates. All friction materials used are non-asbestos, non-toxic and lead-free. Friction materials produced in house – Unique for a clutch manufacturer. Hubs, damper springs, retainer plates and components - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE specifications. Tests include overall plate parallelism, cushion deflection, compressed and relaxed thickness, spring rate and torque capacity/characteristics.

Request for a quote

WESTLAKE EUROPE

Belgium

Castings for Pressure plates are produced in our own factory from high quality cast iron produced in accordance with the requirements of BS1452 and DIN1619. The material must be compact, devoid of blowholes and/or inclusions, crack free and uniform in hardness and texture. Cover pressings are produced using the most sophisticated press equipment available. Pressure Plates, Diaphragm Springs, Straps and all other components undergo strict analysis for chemical composition, tensile strength, hardness and microstructure. All components parts undergo rigorous inspection and measurement controls before entering the production areas. Diaphragm springs - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE load specifications before assembly. Tests including clamp load, release load, pressure plate lift, finger height, stress and fatigue testing using the latest sophisticated test and inspection facilities.

Request for a quoteResults for

Plant testing - Import exportNumber of results

20 ProductsCountries

Company type

Category

- Sensors (2)

- Autoclaves (1)

- Automation - systems and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Electricity - import-export (1)

- Erection and dismantling of industrial plants (1)

- Food flavourings (1)

- High-pressure cleaning machines (1)

- Industrial valves, operating equipment (1)

- Industrial waste management (1)

- Taps - adjustable controls (1)

- Technical textiles for industrial applications (1)

- Wood veneer - machinery and equipment (1)