- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipes for high pressure

Results for

Pipes for high pressure - Import export

KASAG SWISS AG

Switzerland

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Autofrettage is a method for increasing fatigue strength of components for use at high and pulsating pressures. In short, Autofrettage compresses a container’s inner surface, making better use of the material’s structural properties. The process can reduce fatigue concerns in pulsating applications and lets engineers reduce tubing thickness in high-pressure applications without sacrificing strength, life, or safety. The autofrettage method is based on the reciprocal relationship of the plasticized inner zone and the elastically deformed outer zone. The components are placed under so much pressure that their interiors become plastically deformed. After relaxing, pressure stresses are created in these areas, which prevent the outer areas from reforming to their original shape. Instead, it remains stretched. This prevents crack formation in the later application, increases the service life of

Request for a quote

NOVELTY STEEL

Turkey

Piping includes a pipe or system of pipes, pipe spools, tubing, fittings, expansion joints, hoses, or other pressure bearing components as appropriate. Pressure piping systems transport fluids under pressure. Components of pressure piping include: a. Pipes: The main conduits for fluid transport. b. Fittings: Connectors, elbows, and tees that join pipes together. c. Valves: Used to control and regulate the flow of fluids. d. Flanges: Connect pipes to other components like valves, pumps, or tanks. Novelty Steel is an experienced fabricator of pressure vessels for power, oil and gas, chemical, food and mining industries. With vast CNC Machinery Park and experienced engineering team, Novelty Steel produces bespoke CNC Machined parts according to the European Norms. Our fabrication portfolio covers: * Pressure Vessels * Boilers * HRSGs * Heat Exchangers * Pipe Spools * Piping Components * Pipe Supports * Process Skids

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

application: 1. analysis meter 2.pumps 3.light pipes 4.high-pressure water jet 5.shale gas detection

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWAaerob 110 - 1700 ventilation system consists of an oil-free compressor with noise suppressor, a switching system with operating hours counter and a timer, as well as a complete connection fittings set with manometer, check valve and connection line. The ventilation quantity and duration are adjusted by the timer based on the compressor run time. Fine pearls of oxygen are injected from the air. Ideal for short pressure pipes and high flow speeds in the pressure pipe Area of application for pressure pipes <= DN 200 Use with or without accompanying pipe (depending on the high and low points in the pressure pipe)

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

DVK-HD® high pressure pipe couplings are perfect for a quick and well-priced mounting for pressure conveyors. They have the following characteristics: for outer pipe diameter from 60.3 to 206.0 mm length: 100, 150, 200 mm or longer metal casing made of aluminium AlMgSi 0.5 F22 massive aluminium clamps (double secured) screws M12 with massive threaded bars pressure-resistant up to maximum of 12 bar (see table) vacuum-resistant up to maximum of 0.8 bar (see table) circular version, therefore very easy to mount white EPDM gasket or nitrile gasket, temperature-resistant and food-safe optionally available with silicone gasket (-60°C to +200°C) Mounting these pipe couplings is safe and hazard-free because no welding works are necessary. They also can easily be dismantled – connecting pieces and pipes can be reused.

Request for a quote

AVK REWAG

Netherlands

Grip type coupling provides a tensile / axial restraint connection for all metal pipes, allows pipe section replacement, suitable for high pressure, and is available in DN 15-400 Easy installation by use of a torque wrench, limited space required for installation due to compact design Pressure range up to 42,7 bar (620 PSI) depending on size Progressive sealing and anchoring Max. angular deflection 5° for DN 15-50, 4° for DN 65-175 and 2° for DN >= 200 Main components of stainless steel 316 Green PTFE coated bolts Light weight, appr. 30% in comparison with flanged connections 60% noise reduction compared to rigid connections

Request for a quote

AVK REWAG

Netherlands

Grip type coupling provides a tensile / axial restraint connection for all metal pipes, allows pipe section replacement, suitable for high pressure, and is available in DN 15-400 Easy installation by use of a torque wrench, limited space required for installation due to compact design Pressure range up to 42,7 bar (620 PSI) depending on size Progressive sealing and anchoring Max. angular deflection 5° for DN 15-50, 4° for DN 65-175 and 2° for DN >= 200 Main components of stainless steel 316 Green PTFE coated bolts Light weight, appr. 30% in comparison with flanged connections 60% noise reduction compared to rigid connections

Request for a quote

AVK REWAG

Netherlands

Grip type coupling provides a tensile / axial restraint connection for all metal pipes, allows pipe section replacement, suitable for high pressure, and is available in DN 15-400 Easy installation by use of a torque wrench, limited space required for installation due to compact design Pressure range up to 42,7 bar (620 PSI) depending on size Progressive sealing and anchoring Max. angular deflection 5° for DN 15-50, 4° for DN 65-175 and 2° for DN >= 200 Main components of stainless steel 316 Green PTFE coated bolts Light weight, appr. 30% in comparison with flanged connections 60% noise reduction compared to rigid connections

Request for a quote

AVK REWAG

Netherlands

Grip type coupling provides a tensile / axial restraint connection for all metal pipes, allows pipe section replacement, suitable for high pressure, and is available in DN 15-400 Easy installation by use of a torque wrench, limited space required for installation due to compact design Pressure range up to 42,7 bar (620 PSI) depending on size Progressive sealing and anchoring Max. angular deflection 5° for DN 15-50, 4° for DN 65-175 and 2° for DN >= 200 Main components of stainless steel 316 Green PTFE coated bolts Light weight, appr. 30% in comparison with flanged connections 60% noise reduction compared to rigid connections

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Our highest impact solid stream. Interior design featuring minimal pressure drop generates large flow of solid stream jet. Impact of turbulent flow inside the piping can be minimized. Applications High pressure cleaning: Wire and felt parts of paper making machines, vehicles, returnable containers, machinery, parts Trimming: Paper making

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with uniform distribution throughout pattern area. Small 1/8 pipe connection size for high pressure cleaning. Applications High pressure cleaning: Automotive, containers, tanks, wire and felt parts of paper making machines, wire cylinders, filter presses, other industrial cleaning and degreasing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROPEM

Belgium

Europem can supply complete flare systems as well as Flare Tips on their own for replacement or upgrade and refurbishment projects. The following standard Flare Tips are available: EP-PF Pipe Flare EP-EAS External Assist Steam EP-IAS Internal Assists Steam EP-EAS/IAS External/Internal Assist Steam EP-AA Air Assist EP-GA Gas Assist EP-CAA Compressed Air Assist EP-HP-PF High Pressure Pipe Flare EP-HP-MAS High Pressure Multi Arm Sonic EP-MP Multi Point EP-BP Burn Pit Special tailor made Flare Tips can be offered for specific applications. Europem Venturi Flame Shield (VFS) Europem has developed the proprietary Venturi Flame Shield giving double protection against flame lick. The VFS also pushes air up towards tip exit, leading to an enhanced and more stable combustion process. The VFS can be integrated into most Europem Flare Tips but is particularly suitable for H2S flares, ammonia flares, hydrocarbon flares and lean waste gas flares.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Nova Swiss high-pressure pipes and nipples are made from stainless steel and either straightened or bent to custom angles and autofrettaged as required. They are seamless, cold drawn and hardened to ensure high strength and corrosion resistance. During the manufacturing process, the chemical composition and mechanical values of the material are tested and recorded in accordance with strict criteria.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

INOEX GMBH

Germany

WARP 100 is an inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a gapless measurement. This is particularly important for pipes with high quality requirements, such as pressure or gas pipes. The maximum line speed for 100% coverage is up to 11.8 m/min. WARP 100 is available in three sizes and can be used for measurement in the diameter range from 25 to 630 mm. Measured variables such as wall thickness, diameter, ovality, eccentricity as well as process conditions (e.g. sagging) are precisely recorded, documented, and further used for automatic process control. Other advantages/features: — Measurement with 100% pipe coverage in diameter range from 25 to 630 mm (three sizes) — Wall thickness range from 2 up to 125 mm (depending on material) — Detection of thin sections within the tube — 100% documentation of production according to specifications

Request for a quote

ARUBIS

Belgium

In addition to the range of industrial plugs, Plugtite has developed a range of nozzle adaptors to be used during maintenance of hydraulic lines and channels. Resistance to most oils and chemicals Temperature range from -25°C up to 90°C Does not shrink, leak or discolor Resistant to sunlight for greater shelf life Does not split/crack or deteriorate Easy to use. Insert, squeeze, press home and apply air-gun The compressed rubber ensures a tight fit By using the plugtite rubber nozzle adaptor in conjunction with an air gun it prevents splash-back of any oils, chemicals, liquids, or other debris from the channel /tube/pipe whilst cleaning under high pressure, thereby protecting both the user and the environment in and around the equipment from contamination, and, at the same time ensures that all the air pressure is directed into the channel ensuring a stronger pressure for improved performance.

AHP PLASTIK MAKINA

Turkey

The internal pressure creep test is a test procedure for determining the strength of thermoplastic pipes. The samples are subjected to a constant hydrostatic internal pressure at a constant temperature. The high reliability, durability of the material used and the constant temperatures in the test tank with respect to both volume and time provide particularly reliable test conditions. Wide range of tank dimensions and connection options, enables flexibly to various operating conditions. According to ISO 1167 , ASDTM D 1598 , ASTM D 1599 , Pneumatic door , water circulation , digital temperature controller , elastomeric foam insulation , ss304 for contact surfaces with water , outer body is powder coated paint • Have a level control that ensures that the test medium is topped up automatically • It has over-temperature shutdown separate control circuit • The special cir¬cu¬la¬tion system guarantees high accuracy and uniform temperature distribution.

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

SANHA GMBH & CO. KG

Germany

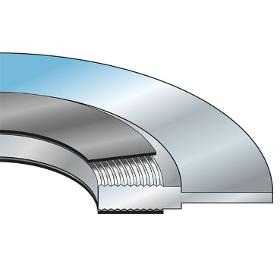

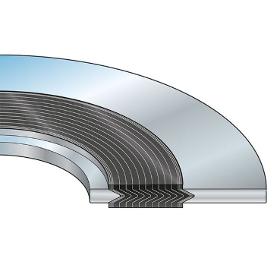

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Reducing coupling

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Bend 45° F/F

Request for a quoteResults for

Pipes for high pressure - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Connectors, plumbing (10)

- Hoses, pipes and tubes - plastic (4)

- Pumps (4)

- High-pressure cleaning machines (2)

- Gear pumps (2)

- Nozzles - ferrous metal (2)

- Piston pumps (2)

- Testing equipment (2)

- Air-conditioning systems, vehicles (1)

- Autoclaves (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Coupling, pneumatic (1)

- Finished Metal Products (1)

- Industrial piping (1)

- Motor mechanics - hand tools, non power (1)

- Precision measuring instruments (1)

- Rubber products (1)

- Steels, nickel (1)

- Valves, hydraulic (1)

- Water - production and distribution (1)